kelly hose specification factory

Flexible drilling rubber hoses play an important role in petroleum extraction. They should suffer high operating pressure, extreme operating temperature, abrasion and other inferior elements. Our special compounded synthetic rubber has been proven an effective and economical way to reject these problems. All our oilfield drill hoses are manufactured as API 7K or other related specifications.

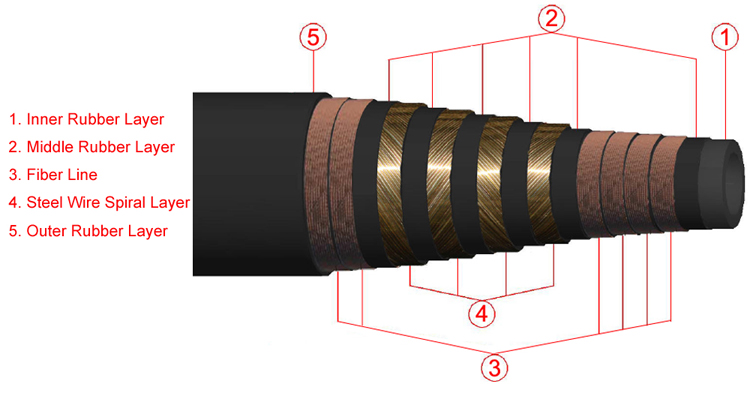

Steel cable reinforcement loads most working pressure up to 15,000psi. The wires are usually zinc-plating or copper platting to improve steel wire resistant against rust and corrosion. Due to the thick reinforcement, the hoses should be handled or stored in correct way to avoid kicking or crushing. They will substantially decrease their rated operating pressure.

Rotary hose, Kelly hose, cement hose, mud hose, jumper hose and vibrator hose and choke & kill hoses are the most popular oilfield rubber hoses. They convey high-pressure drilling fluid from one place to another. Many end fittings are provided to satisfy different applications. Most end fittings are made according to API standards. Special order is also available.

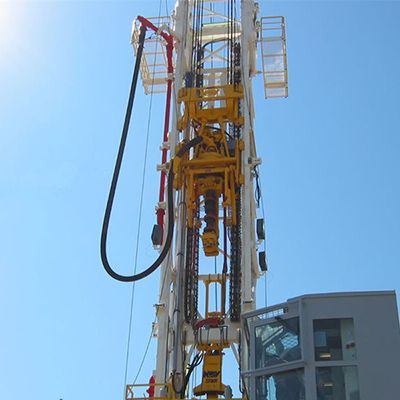

Kelly hose is used to connect the standpipe to the swivel. It allows the drill string to be raised and lowered while the drill fluid is pumped through it. Kelly line usually contains two layers of plated steel cables to reach 5000 psi operating pressure. Inside tube is made of special NBR to improve abrasion and corrosion capability. Rubber cover is compatible with the ozone, sunlight and oils for a long time. It is supplied with multiple end fittings – API flanges, threads, butt-welded union and other as specified.

Flexible connection between standpipe and swivel (Rotary Drilling) or between pump and standpipe (Rotary Vibrator) for pumping mud at extra high pressure in oil drilling and exploration work. Meets the high demands of directional drilling and down linking with negative pressure pulses and elevated temperatures. This hose can also be used as a Motion Compensator hose for stabilization of rotary drilling and pumping equipment against vertical wave action on offshore drill platforms. The Motion Compensator hose is not recommended for phosphate ester fluids.

The kelly rotary drilling hose is flexible Connection between standpipe and swivel(Rotary Drilling) or between pump and standpipe(Rotary Vibrator) for pumping mud at extra high pressure in oil drilling and exploration work. Kelly Rotary drilling hoses are used in oil fields, well cementing, well repairing, geological explorations, small drilling machine, and water

A rotary/pumper hose is used in oil well drilling. It acts as the crucial instrument in the connection being made between the standpipe and the swivel.

A rotary hose is also used as a means of permitting the kelly to be either raised or lowered through the drilling process while also allowing the drill bit to be raised with the drillstring. For this reason, it is also often referred to as a “kelly hose.”

Rotary hoses also function during the process that allows the drilling fluid to be pumped through the hose when the bit and drillstring are raised and lowered.

This process is imperative in the completion of the drilling process. The drillstring portion of the drilling line and the connection to the rotary hose is thus crucial.

A large-diameter (3- to 5-in inside diameter), high-pressure flexible line used to connect the standpipe to the swivel. This flexible piping arrangement permits the kelly (and, in turn, the drillstring and bit) to be raised or lowered while drilling fluid is pumped through the drillstring. The simultaneous lowering of the drillstring while pumping fluid is critical to the drilling operation.

Made of heavy rubber and steel cables the hose is basicly flexible piping that allows the Kelly and the bit and drill string to be raised and lowered while the drilling fluid is pumped through drill string.

lowering the drill string and pumping drilling mud is very important to the drilling process and when these hoses go down or fail in service a entire rig can shut down.

Made of heavy rubber and steel cables the hose is basicly flexible piping that allows the Kelly and the bit and drill string to be raised and lowered while the drilling fluid is pumped through drill string.

Rotary Drilling/Pumper hose is mainly used for conveying water-based or oil-based mud and other fluids in the working temperature of -30 °C to +82 °C.

The reinforcement is made from 2-8 layers of high tensile and high strength spiraled steel wire, making the hose have solid structure and resistant to high pressure.

The cover is made from high quality synthetic rubber, mainly chloroprene rubber, making the hose resistant to abrasion, corrosion, cut, weather, ozone, aging and sunlight.

A Kelly hose (also known as a mud hose or rotary hose) is a flexible, steel reinforced, high pressure hose that connects the standpipe to the kelly (or more specifically to the goose-neck on the swivel above the kelly) and allows free vertical movement of the kelly while facilitating the flow of drilling fluid through the system and down the drill string.

Flexible drilling rubber hoses play an important role in petroleum extraction. They should suffer high operating pressure, extreme operating temperature, abrasion and other inferior elements. Our special compounded synthetic rubber has been proven an effective and economical way to reject these problems. All our oilfield drill hoses are manufactured as API 7K or other related specifications.

Steel cable reinforcement loads most working pressure up to 15,000psi. The wires are usually zinc-plating or copper platting to improve steel wire resistant against rust and corrosion. Due to the thick reinforcement, the hoses should be handled or stored in correct way to avoid kicking or crushing. They will substantially decrease their rated operating pressure.

We are global leader in the design, manufacture and supply of high pressure hoses.As drilling operation methods evolve, become deeper, with increasing pressure and higher temperatures,

We have over 50 years of experience in metallic reinforced bonded elastomer hoses and has been the first company to obtain certification for all three governing industry standards: API 7K, 16C and 17K standard.

We have since built up a broad portfolio for a variety of drilling applications, such as flexible choke & kill Lines, rotary & vibrator hoses, managed pressure drilling hoses to meet the needs of both onshore & offshore drillers and distributors.

Our key offering includes rotary drilling / vibrator hose grade D and E, choke and kill, cement and sour hoses. The supports the pumping of mud at very high pressure during drilling and exploration campaigns.

Protects the polymer lining from mechanical damage, prevents blistering in case of high pressure gas service and decompression with vacuum service, supports the wall of the flexible hose.

The lining material is selected to withstand chemical and heat effects of drilling mud, well effluents, cement slurry, hydraulic fluid or whatever substance is conveyed through the hose.

High-pressure mud hose also called rotary hose, vibrator hose or jumper hose, is used to convey drilling fluid from mud pump to the mud standpipe manifold on the drill floor.

The high pressure hoses are a bonded construction comprising steel and elastomeric materials. The principal characteristic of bonded construction is the build-up of individual layers in the flexible hose wall which are then combined into one unit through vulcanisation. Hose assemblies are manufactured as a single bonded unit to specified lengths where the couplings are a chemically bonded integral part of the hose.

Protects the polymer lining from mechanical damage, prevents blistering in case of high pressure gas service and decompression with vacuum service, supports the wall of the flexible hose. This layer is optional and present only for rough bore hoses, such as for flexible choke & kill lines with TauroFlon™ liner.

Fluid barrier of the flexible line. Protects the hose construction from corrosive and abrasive effects of the conveyed medium. The thickness of lining depends on the internal pressure, the inside diameter and the conveyed medium. The lining material is selected to withstand chemical and heat effects of drilling mud, well effluents, cement slurry, hydraulic fluid or whatever substance is conveyed through the hose.

From 2003, Letone has always been committed to manufacturing rubber hose for 14 years, which provides high-grade and high-end rubber hose for the field of spaceflight and maritime industry, petroleum industry and highway, and PLA etc. Just as careful and elaborate rubber hose, LETONE has now become a high-tech enterprise integrating research, production, sales and services after years of steady development, shining brilliantly in the international market as an iconic enterprise among China"s rubber hose.

8613371530291

8613371530291