what is a mechanical seal manufacturer

A mechanical seal is simply a method of containing fluid within a vessel (typically pumps, mixers, etc.) where a rotating shaft passes through a stationary housing or occasionally, where the housing rotates around the shaft.

When sealing a centrifugal pump, the challenge is to allow a rotating shaft to enter the ‘wet’ area of the pump, without allowing large volumes of pressurized fluid to escape.

To address this challenge there needs to be a seal between the shaft and the pump housing that can contain the pressure of the process being pumped and withstand the friction caused by the shaft rotating.

Before examining how mechanical seals function it is important to understand other methods of forming this seal. One such method still widely used is Gland Packing.

Packing needs to press against the shaft in order to reduce leakage – this means that the pump needs more drive power to turn the shaft, wasting energy.

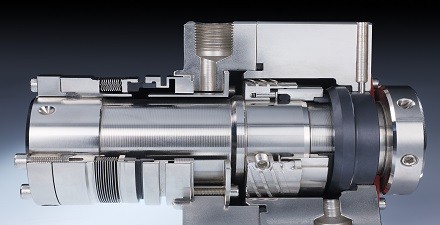

The stationary part of the seal is fitted to the pump housing with a static seal –this may be sealed with an o-ring or gasket clamped between the stationary part and the pump housing.

The rotary portion of the seal is sealed onto the shaft usually with an O ring. This sealing point can also be regarded as static as this part of the seal rotates with the shaft.

One part of the seal, either to static or rotary portion, is always resiliently mounted and spring loaded to accommodate any small shaft deflections, shaft movement due to bearing tolerances and out-of-perpendicular alignment due to manufacturing tolerances.

The primary seal is essentially a spring loaded vertical bearing - consisting of two extremely flat faces, one fixed, one rotating, running against each other. The seal faces are pushed together using a combination of hydraulic force from the sealed fluid and spring force from the seal design. In this way a seal is formed to prevent process leaking between the rotating (shaft) and stationary areas of the pump.

If the seal faces rotated against each other without some form of lubrication they would wear and quickly fail due to face friction and heat generation. For this reason some form of lubrication is required between the rotary and stationary seal face; this is known as the fluid film

In most mechanical seals the faces are kept lubricated by maintaining a thin film of fluid between the seal faces. This film can either come from the process fluid being pumped or from an external source.

The need for a fluid film between the faces presents a design challenge – allowing sufficient lubricant to flow between the seal faces without the seal leaking an unacceptable amount of process fluid, or allowing contaminants in between the faces that could damage the seal itself.

This is achieved by maintaining a precise gap between the faces that is large enough to allow in a small amounts of clean lubricating liquid but small enough to prevent contaminants from entering the gap between the seal faces.

The gap between the faces on a typical seal is as little as 1 micron – 75 times narrower than a human hair. Because the gap is so tiny, particles that would otherwise damage the seal faces are unable to enter, and the amount of liquid that leaks through this space is so small that it appears as vapor – around ½ a teaspoon a day on a typical application.

This micro-gap is maintained using springs and hydraulic force to push the seal faces together, while the pressure of the liquid between the faces (the fluid film) acts to push them apart.

Without the pressure pushing them apart the two seal faces would be in full contact, this is known as dry running and would lead to rapid seal failure.

Without the process pressure (and the force of the springs) pushing the faces together the seal faces would separate too far, and allow fluid to leak out.

Mechanical seal engineering focuses on increasing the longevity of the primary seal faces by ensuring a high quality of lubricating fluid, and by selecting appropriate seal face materials for the process being pumped.

When we talk about leakage we are referring to visible leakage of the seal. This is because as detailed above, a very thin fluid film holds the two seal faces apart from each other. By maintaining a micro-gap a leak path is created making it impossible for a mechanical seal to be totally leak free. What we can say, however, is that unlike gland packing, the amount of leakage on a mechanical seal should be so low as to be visually undetectable.

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

A.W. Chesterton® is a manufacturer of industrial fluid sealing and maintenance products including hydraulic seals, pneumatic seals, mechanical seals and packing, oil seals, o-ring seals, metric seals, lip seals and many other products. We are ISO 9001/14001 and MRP II Class A certified.

AccroSeal® is committed to manufacturing high quality seals to your design at competitive prices. The AccroSeal® technical sales team works directly with your engineering department to solve the most difficult sealing applications. Our sealing product portfolio includes wipers, lip seals, o-rings, piston rings, v-rings, and more produced from our exclusive Accrolon® engineered compounds.

American High Performance Seals Inc. designs and manufactures hydraulic seals, rotary shaft seals, oil seals, gaskets and other high performance rubber and plastic parts. AHP Seals designs and manufactures the most durable seals available and delivers them within 1-4 days.

Since 1981, American Seal Supply Co. has been distributing top-quality fluid seals and packing to its varied customer base. Among our product offerings are oil seals, rubber seals, o-ring seals, metric seals, Teflon® seals and lip seals. We also supply hard-to-find and custom-made seals.

American Seal & Packing is a leading manufacturer & distributor of mechanical seals, Grafoil, gasket material, cut gaskets and quality o-rings. We are constantly working to provide innovative solutions to mechanical seal problems. With our wide selection of products we"re finding better ways to serve our customers all the time. Contact our expert staff for a quote to meet your needs.

Appleton Packing and Gasket was born out of the need for better service. Among the many products we offer are mechanical seals, oil seals, gaskets, mechanical packings and o-rings. We attribute our success to the trust placed in us by our customers. Our continuing goal is to offer outstanding quality products at competitive pricing, in a manner which will best satisfy customer needs.

Beacon Gasket & Seals Co. is fully tooled to cut your requirements from compressed non-asbestos, gylon, gore-tex, flexible graphite, teflon, silicone, red rubber and neoprene rotary seals and other hydraulic sealing systems. Specializing in MTBF Solutions and representing the best manufacturers in the industry, we are excited about our expanding product offerings and the opportunity to serve you.

CoorsTek provides custom engineering, materials expertise, operational excellence and rapid execution to make our world measurably better! Technical ceramic, engineering plastic and specialized metal components help us build tomorrow’s technology. CoorsTek hydraulic seals offer extreme-temperature, high-pressure, chemically inert, static and dynamic seals for the most demanding applications.

CW Marsh offers you the best of both worlds: the toughest, most versatile natural material available for sealings and the benefits of a century of technological advancements and product innovation. CW Marsh produces leather vee packings, cups, u-packings, flanges, and back-up washers, all manufactured and backed with the same old-world dedication to quality, service and dependability.

At D&D Engineered Products Inc. we manufacture top of the line hydraulic seals, gaskets, various o-rings, high temperature tapes, compression packings, and much more. We promise to cater our product to any needs you may have, such to ensure your satisfaction. If you would like more information please give us a call.

East Texas Seals, Inc. is a distributor of O"Rings and Gaskets for Parker Seal. If you need an O"Ring, Seal or Gasket, we can fulfill your needs. We have supplied the Oil Field industry with O"Rings to adequately keep their oil rigs up and running. East Texas Seals, Inc. works closely with the U.S. Government and Defense departments, shipping and storage companies and all commercial sectors.

EPM, Inc. is your one stop shop for seals, with billions of styles including rod seals, piston seals, symmetrical seals, V-Rings, wipers, rotary shaft seals, wear rings, static seals, back-up rings, o-rings, buffer rings, u-cups, oil & grease seals, cast iron piston rings and gaskets. Whether you need one or one million, EPM offers fast turnaround and great prices on seals up to 21inches or 600mm.

With an extensive customer service center for catering to customer needs, Freudenberg-NOK manufactures a number of different seals. These offerings include hydraulic seals, pneumatic seals, o-ring seals, rod seals, piston seals and pump seals.

Garlock Sealing Technologies is the global leader in high-performance fluid sealing products for the world’s processing industries. Their 12 manufacturing facilities in the U.S., Canada, Europe, Asia and Latin America collectively produce the broadest range of fluid sealing products designed specifically for industrial applications. Some products include metal gaskets, o-rings and oil seals.

Here at Gasket & Seal Fabricators, we supply die cut, lathe cut, extruded, molded and spliced gaskets of all types, sizes and shapes. We specialize in both commercial and military spec materials, including many UL, FDA and NSF recognized materials. Our in-house capabilities include various types of die cutting equipment such as punch presses, both manual and automatic roll feed, clicker presses, and beam presses. Contact us for more information!

We manufacturer high quality hydraulic seals that are ideal for a wide range of industries. Here at Global O-Ring and Seal, LLC we are a trustworthy manufacturer who is known for our ability to adhere to all of your special requests. These seals come in a number of different materials including Buna, Viton, Silicone, Teflon, Aflas and more. Please give us a call today to learn more!

Greenville Industrial Rubber & Gasket is your source for industrial rubber products and accessories. For over 35 years, we have been providing the industry with top-quality rubber products including: gaskets, conveyor belts, packing, hoses, industrial hose fittings and hydraulics. In addition to industrial rubber products, we also stock a wide selection of safety products, adhesives, and other accessories.

We are a preferred supplier to most of the leading global manufacturers of hydraulic equipment, air compressors, transmissions, hydraulic clutches, valves and shock absorbers. We manufacture hydraulic seals and pneumatic seals among other products. Let us work together to enhance your applications.

Over 100 years, Hallite Seals International has been at the cutting edge of fluid power technology, manufacturing a wide range of rod / gland, piston, and static seals, as well as support and bearing components, for technically challenging applications, from a wide range of materials which include Polytetrafluoroethylene (PTFE), Polyurethane (AU), nitrile rubbers (NBR) and Fluoro-elastomers (FKM).

For over 34 years, Harwal has continued to be the leader in metric oil seals. With one of the largest seal selections, 1,000,000 seals in 7,000 different sizes in stock, be assured we"ve got what you need. We also offer V-rings, standard inch sizes, end caps, Teflon® seals, wipers and gamma seals!

For over 34 years, Harwal has continued to be the leader in metric oil seals. With one of the largest seal selections, 1,000,000 seals in 7,000 different sizes in stock, be assured we"ve got what you need. We also offer V-rings, standard inch sizes, end caps, Teflon® seals, wipers and gamma seals!

Hi-Tech Seals is capable of either creating parts with our in-house machining department or utilizing our relationships with industry leading seal manufactures. Our sales staff works with customers to find the best solution to replicate existing or design new parts. Different manufacturing options include machining, molding and extrusion.

At HydraPak, we make replacing your hydraulic seals easy, so you can get your seal repair jobs completed quickly, saving you time money. Even the most difficult seal repair challenges can be handled by our knowledgeable staff to get your equipment. We offer expertise in products for high-tech applications, as well as the ability to source everything from o-rings to sheet goods to sealing devices.

Being a seal manufacturer and distributor, JEM Seal Co. offers mechanical seals, hydraulic seals, oil seals, rubber seals, and more. Our mining equipment industry seals are used exclusively by Hallite Mining. Our stock of piston seals, rod seals, and wipers are in stock for your specific needs.

Encapsulated O-ring manufacturer and Precision extruder M-Cor Inc. is a leading U.S. producer of high performance sealing products for extreme environments. Extruded profiles are converted into o-rings, Teflon® encapsulated o-rings, camlock gaskets, chemical transport tubing and other sealing products. With in house tooling capabilities, we are able to immediately respond to customer requests.

Martin Fluid Power distributes on a worldwide basis, hydraulic seal repair kits, o-ring seal repair kits, metric seals, Teflon® seals and a lot of other types of seals, plus gaskets and packing. Our products come in many different shapes, sizes, materials and colors to suit your specifications.

Speed is of the essence at Michael-Stephens Co. Within 24 hours of your request, we can customize nitrile oil seals for you in a variety of profiles and materials. We work with a wide range of Teflon®-filled items. We also supply hydraulic seal kits; our website lists the wide range of manufacturers we carry.

Pacific International Bearing is capable of providing solutions for all types of applications with an educated and committed staff here to service your needs. PIB offers quality seals from Chu Hung Oil Seals Industrial Company (manufactured in Taiwan). They hold ISO 9001 Quality Certificates to provide top quality oil seals. Seals come in a variety of sizes and lip designs to suit your need.

With over 175 years of accumulative sealing experience, this team has helped pioneer the development of high performance seals around the world. Our core people excel at innovative seal design, high performance materials utilization, and efficient production techniques with a Certified ISO 9001: 2000 and AS9100 Rev. Some products of ours include, rotary shaft, rod and piston seals.

We are not only technically knowledgeable about hydraulic seals, but we also have the hands-on experience to back it up. We have over 30 years of industry experience, and we can use that experience to benefit you. We have faced nearly every problem and know the right solution for most problems. We can offer both stock and custom seals to benefit you. We will always put the customer first, so contact us today!

R&B Plastics is a supplier of custom machining serving a variety of industries including electronic connectors, plastics, filters, bearings, hydraulics and valve seals. With 34 years experience, R&B Plastics provides quality products to both the U.S. Government and major aerospace companies such as Boeing Corporation.

R.T. Dygert International is one of the largest distributors located in Minneapolis, MN and an office/warehouse in Niles, IL. RT/Dygert International prides itself on its responsive, service-driven culture and its reputation for its core values of quality, honesty and integrity and committed to a process of continuous improvement. Some of the products include piston and rod seals and o-rings.

Seal Master® specializes in manufacturing custom-built inflatable seals. These products include metric seals and rubber seals available in different sizes and shapes. Our seals are used in a wide variety of applications, including valves, robotics, conveyors, gates, brake devices and actuating devices.

Established in 1979, Southwest Seal and Supply has grown to become one of the most predominant distributors of sealing, hydraulic hoses, fittings, couplings/connectors, gasketing and fluid control products in the Southwest. We offer a wide range of products including the best in selection, quality, and value-added services.

System Seals offers a complete range of industrial hydraulic seals: small or large diameter, low or high pressure, reciprocating or rotary motion, dynamic or static sealing. We carry in-stock standard sizes plus are flexible enough to cater to all sizes. Rod Seals, Piston Seals, wipers & guide elements.

The T-Bird Group is a collection of distributors and manufacturers of seals, bearings, v-packings, unified pistons, wear rings, wipers, wear strips, u-cups, and machined plastic components.

Texacone Company, Inc is a manufacturer of fabric-reinforced elastomer and urethane molded products. Texacone specializes in molded seals up to 65" diameter in solid or split from a wide variety of fabric-reinforced elastomers. High temperature materials also available. Some of our products are: v-rings, flared u cup, piston cups and flanges.

Mechanical seal varieties are used to prevent the unwanted release of pressure, lubricants, hydraulic fluids and other properties of a system that makes use of them. Seals are also used to prevent the contamination of those systems by dirt and other hazards. Equipment like agitators, mixers, gas seals, pumps, valves, actuators and many other kinds of machinery all involve the use of some variety of mechanical seal.

In addition to preventing leaks, mechanical seals also keep contaminants from entering and help to maintain pressure levels. Piston seals, flange gaskets and diaphragm seals are also kinds of mechanical seals, and they are all essential to the functioning of certain kinds of equipment.

Most mechanical seals are specially designed to prevent leaks in particular applications and cannot be interchanged with those seals used in other mechanisms. A piston seal, for example, cannot be used as a flange gasket; they are shaped differently, made out of different materials and feature different mechanical properties. The shape, size, and composition of a given mechanical seal always depends on the conditions in which it will be applied.

Also, depending on the narrowness or broadness of a given understanding of the words "mechanical seal," certain kinds of seals may or may not qualify. Simple plastic lids qualify by the broadest definitions, while some of the strictest definitions might only include seals applied in industrial process equipment or in heavy machinery.

In either case, mechanical seals perform the same task: to isolate and contain materials in an enclosure. Correctly pairing seals with their applications is essential to the safe and effective use of the equipment in which they are installed. For example, Teflon is often chosen for use in hydraulic cylinders because it is resistant to corrosion induced by exposure to hydraulic fluids.

Natural rubber, on the other hand, may degrade when exposed to such chemicals. The decision to employ a given seal material should always be chosen carefully; this will ensure sustained effective and safe operation of the seal and the equipment it protects.

Usage of mechanical seals across the industrial spectrum is increasing rapidly as the seals do not cause or accelerate shaft wear and tear and the materials themselves have a long shelf-life. Moreover, introduction of new technologies is also a major element boosting the overall growth of the global mechanical seal’s market. However, mechanical seals manufacturers must have the flexibility towards market change, and the ability to innovate as per the changing market dynamics. These changes should be both in terms of production designs and as well as in the business processes.

Power machines that have a rotating shaft, such as pumps and compressors, are generally known as “rotating machines.” Mechanical seals are a type of packing installed on the power transmitting shaft of a rotating machine. They are used in various applications ranging from automobiles, ships, rockets and industrial plant equipment, to residential devices.

Mechanical seals are intended to prevent the fluid (water or oil) used by a machine from leaking to the external environment (the atmosphere or a body of water). This role of mechanical seals contributes to the prevention of environmental contamination, energy saving through improved machine operating efficiency, and machine safety.

Shown below is a sectional view of a rotating machine that requires the installation of a mechanical seal. This machine has a large vessel and a rotating shaft at the center of the vessel (e.g., a mixer). The illustration shows the consequences of cases with and without a mechanical seal.

If the aim is solely to prevent leakage from the machine, it is effective to use a seal material known as gland packing on the shaft. However, a gland packing tightly wound around the shaft hinders the motion of the shaft, resulting in shaft wear and therefore requiring a lubricant during use.

Separate rings are installed on the shaft and on the machine housing to allow minimal leakage of the liquid used by the machine without affecting the rotating force of the shaft.

To ensure this, each part is fabricated according to a precise design. Mechanical seals prevent leakage even with hazardous substances that are difficult to mechanically handle or under harsh conditions of high pressure and high rotating speed.

A mechanical seal is installed on the impeller rotating shaft. This prevents the liquid from leaking through the clearance between the pump body and the shaft.

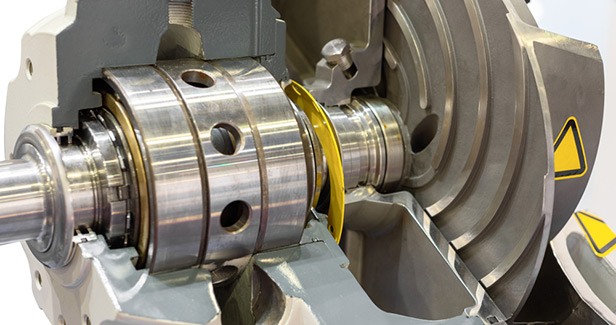

The rotary ring rotates with the shaft. The stationary and rotary rings rub against each other ensuring a clearance in the order of micrometers maintained between them. Where they rub against each other, they are referred to as “face materials.”

The face materials where the stationary ring and the rotary ring rub against each other are the most important portions as a barrier to the fluid. If the clearance is too small, the friction increases, hindering the shaft motion or resulting in seal breakage. Conversely, if the clearance is too large, the liquid will leak. Consequently, it is necessary to control the clearance in the order of micrometers to prevent leakage, but at the same time ensuring lubrication by the fluid, thereby reducing the sliding torque and avoiding hindrance to the machines’ rotation.

The mechanical seal technology is a sum of mechanical engineering and physical property technology due to the above-mentioned functions and applications. More specifically, the core of the mechanical seal technology is the tribology (friction, wear and lubrication) technology used to control the surfaces where the stationary and rotary rings rub (slide) against each other.

Mechanical seals with improved functionality will not only prevent the liquid or gas handled by a machine from leaking to the outside, but also improve machine operating efficiency, thereby helping achieve energy saving and prevent environmental contamination. Moreover, in some cases, rotating machines handle media that, in the case of leakage, can lead to a dangerous accident. Therefore, mechanical seals are required to be highly reliable through manufacturing backed by solid engineering expertise.

These functions and roles will make mechanical seals increasingly important functional parts in the future. Their further technical innovation is anticipated. To positively respond to these expectations, Eagle Industry is working on technical research and development every day.

The mechanical seal technology was fundamentally established in the 1960s. Thereafter, it has been making significant progress by introducing various leading-edge technologies, and innovative mechanical seals created from the above advanced technology are continuously being put to practical use.

To meet the demands of the market sufficiently, an applicable range of the “pressure” and “rotation speed” of mechanical seals has been considerably extended since the beginning of the 2000s. This is due to advancing of the tribology technology such as to enhance a function of the sliding materials (e.g., composite material composition, coating technology) and/or a performance of the sliding surfaces based on the fluid lubrication theory (e.g., non-contact mechanical seal, surface textured mechanical seal). These advanced technologies are sustained by improvement in the element technology of numerical analysis, processing/production, physical property/composition analysis, measurement, verification test, and so on.

Source: “Current status and future prospects of a wind/hydraulic machinery industry from 2021 to 2025”, The Japan Society of Industrial Machinery Manufacturers (2021).

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

... pressurized gas barrier metal bellows seal utilizing APGS non-contacting seal face technology. Welded metal bellows eliminate dynamic O-ring hang-up in a compact cartridge that fits ANSI and DIN standard ...

• Drive mechanisms external to the product;• Seal faces positioned for maximum protection;• A dynamic elastomer moves on a non-metallic surface, eliminating fretting defects;• Hydraulically balanced;• Cartridge easy to ...

• Static grafoil gaskets;• Temperatures up to 425 ºC;• Inconel bellows available;• Cartridge easy to install;• Metal bellows provide better faces alignment;• Does not have dynamic gaskets;• Self-cleaning;• Adapts to API standard pumps;• ...

Burgmann H74-D Mechanical Seal called as PC04 are specialized in mechanical seals products. This device gives double seal and it can be rotated in any ...

The M7N series is made of compact structure. It has a various application scope and high interchangeability. This series is widely used in petrochemical pumps. It is also embedded with drive collar that is clamped by the drive lug, in ...

The MTM10-11 is a conical spring mechanical seal developed by Microtem. It is mainly used for general services machinery at low and medium pressure. This unbalanced mechanical seal ...

The MTM 15, manufactured by Microtem, is a series of conical springs that are used for general services machinery at low and medium pressure. They can be made up of aluminum oxide, silicon carbide SiC, carbographite impregnated with antimony, ...

The MTM 25_26, manufactured by MICROTEM, is a conical spring mechanical seal that can compensate positioning errors and withstand stresses created by vibrations. The contact surface can be made with silicon ...

... agitators on sealed tanks will have a mechanical seal of some sort. For many sanitary process vessels, the mixer must have some type of sealing barrier to provide either a dust tight vapor seal, ...

mechanical seal for automotive engine cooling water pump, referred to as water seal, mainly composed of two parts: rotating ring and static ring. Static ring is installed in the pump ...

The 3-D Seal is designed to be the foremost solution for high radial misalignment and high run out applications. By combining Garlock’s proven P/S®-II and expansion joint technologies into ...

Aura™ reduces operational and transactional costs using a patented polymeric sealing device. Aura reduces leakage rates by up to 15 percent, lowering the total cost of operation while protecting the environment. An enhanced rotor design ...

The AESSEAL® API Type A, B and C single-seal range offers the user an unprecedented range of API engineered sealing solutions to suit all application ...

Mechnical seal type 5030 / 5031 »with rubber bellowssingle-actingnon-anisotropicAreas of usestandard pumpwaster water pumpsupply engineeringgeneral industrial usemass production seal

When purchasing the units, if left hand rotation, special seal, or a particular position of cartridge (shaft end or cover end) is needed, it should be ...

Cartridge Seals by CinchSeal are customized mechanical seals for rotary air locks in bulk handling equipment. They are designed to replace lip and packing seals in screw ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

We specialize in hard-to-find seals and demanding applications. Our extensive network of resources enables us to locate the right manufacturer and part, every time.

At All Seals we know down time is not an option. We specialize in hard-to-find seals and demanding applications. With over 40 years of experience in supplying quality replacement mechanical seals, we can help you identify the seal you need and solve your sealing problem. Our technical staff is available to help you – just give us a call. Our comprehensive stock of components ensures that we can build almost any seal combination for same day shipment. Whether you need a new seal or you have a seal to be repaired, we welcome the opportunity to help you with your rotary sealing needs.

We carry a comprehensive inventory of mechanical seal components, which allows us to build the right seal for your application. We’ll even design custom seals for one-of-a-kind applications.

Our goal is to make your repair easy without compromising on quality. Repair kits greatly reduce costly downtime, saving costs while sustaining production. Our pump rebuild kits are supplied with the same components you’ll find in an OEM kit; however, we offer them at a fraction of the price.

Need hard faces or specialty elastomers? Give us a call. We can quickly build a repair kit to withstand any medium being pumped. You’ll find All Seals’ pump repair kits an invaluable part of your operation.

The global mechanical seals market size stood at USD 3.20 billion in 2018 and is projected to reach USD 4.77 billion by 2026, exhibiting a CAGR of 5.2% during the forecast period.

The key utility of a mechanical seal is to prevent leakage of fluids or gases through the clearance between the shaft and the container. Mechanical seals consist of a set of 2 faces separated by carbon rings. The first face is in contact with the rotating equipment whereas the second face is stationary. Moreover, the main part of the seal is the seal ring (first face) on which the mechanical force is acting, generated by springs, bellows, or fluids in the equipment. In recent years, mechanical seals are playing an important role in varied industrial applications, enabling efficient operations. Mechanical seals are made up of several flexible materials such as Polytetrafluoroethylene (PTFE), Polyurethane (AU, EU), industrial rubber, Fluorosilicone (FVMQ), and many more.

The mechanical seal market has depicted significant growth in the recent span of years and is likely to grow in the forecasted period. Rising industrial development in emerging economies is expected to initiate additional development policies and investments. Major types of mechanical seals available in the market include cartridge seals, balanced and unbalanced seals, pusher and non-pusher, and conventional seals that are influencing the mechanical sealing market growth in developing countries.

Growth in machine tool industry is impelling the overall market share, owing to the usage of power machines in centrifugal pumps and compressors for sealing and separating the fluid in the rotating shafts. Hence, the increasing market demand for mechanical seals in various industries is anticipated to drive the market growth in the near future. Furthermore, the highest market growth is projected to be witnessed in Asia-Pacific, followed by North America.

According to the United Nations Conference on Trade and Development (UNCTAD), the global foreign direct investment (FDI) will grow vigorously in 2018. This implies that there will be strong growth in the manufacturing sector in the coming decade. Moreover, many countries are now adopting investment policies that will boost the manufacturing sector and drive the mechanical seals market trends. For instance, in 2017, several countries and economies adopted investment policy measures across the globe, of which 84% of countries were favorable to investors. This will allow investors to invest their funds in various industries, with primary focus on energy, transportation, and manufacturing.

Furthermore, many manufacturing and industrial studies are more focused on the production or supply side and less on the demand side. This practice has reduced the importance of the manufacturing sector over the last few decades. This situation can get balanced by placing the demand side at center in the manufacturing sector ecosystem.

Therefore, the demand for manufacturing is increasing with the changes in investment policies of multiple developed and developing countries. This growth will increase the adoption of machine tools and industrial equipment for the manufacturing process, which will directly boost the mechanical seals market growth, globally.

The global mechanical seals market is segmented by type, which is further segmented into pusher and non-pusher, conventional seals, balanced and unbalanced seals, and cartridge seals.

Continuous adoption of advanced sealing material in several industries is expected to grow the cartridge seals segment in the forecast period. The cartridge seals segment is estimated to have exponential market opportunities as they are designed as universal shaft seals for the seal chamber of pumps, containers, or pipelines.

The pusher and non-pusher seals segment depicts substantial growth, owing to the increasing usage of small and large diameter ring shaft in the light end services to handle high temperatures. The balanced and unbalanced mechanical seals segment is anticipated to grow moderately, owing to the rise in the industry sector worldwide. Balanced seals are preferred for most of the industrial applications as they generate less heat at the surface of the machine, enabling longer seal life and efficient sealing method.

Comparatively, the conventional seal segment is projected to witness progressive growth owing to the requirement of heat exchanger mating ring advances offered by these seals. The other segment consists of bellows seals and is likely to represent steady growth due to limited demand in the mechanical sealing market.

By industry, the market is bifurcated into metals and mining, food and beverage, oil and gas, energy and power, aerospace, marine, construction and manufacturing, and others (chemical, etc.).

Oil and gas industry is anticipated to grow exponentially at a higher growth rate owing to increasing demand of petroleum from developed and emerging countries, hence boosting the demand of mechanical seals. Energy utilization is growing worldwide and influencing the demand for electricity generation and consumption rate, thus leading to remarkable market growth. In the current scenario, 70% of the electricity is generated from the renewable sources such as wind and solar power, which bodes well for the mechanical seals market demand.

The construction and aerospace sectors are projected to depict significant market opportunities owing to the rising infrastructural developments as a result of increasing population and technological advancements in the aerospace operating and navigation systems.

Mechanical seals demand is increasing in the food and beverage and mining sectors due to increasing implementation of pumps, food tanks, and many other centrifugal machines to manage the intensity of fluid. Marine sector is expected to depict substantial market growth as the need for the mechanical seals at naval ships and ports will remain steady in the forecast period. The others segment consists of chemical industry and is likely to showcase steady growth, owing to minimum demand in the mechanical sealing market.

Asia-Pacific is anticipated to lead the mechanical seals market share and is projected to depict exponential growth over the forecast period due to the increasing industrial applications in the emerging countries including India and China. Along with that, strong economic growth in the manufacturing sector is expected to fuel the development of the market in the region. Furthermore, favorable regulatory framework and regulations by governments for increasing investment in the manufacturing industry is expected to have a substantial impact in the growth of the market. Additionally, rapid industrialization and increasing demand of mechanical seals from industries such as construction, marine, energy and power, and oil and gas is expected to boost the growth of the market. Moreover, the region has several small and medium mechanical seals manufacturers which will increase the market share of the Asia-Pacific region in the forecasted period.

North America is predicted to show a dynamic growth rate over the projected timeline due to the rising number of infrastructure and other development projects in the region, the mechanical seals market analysis points out. This growth in the region is attributed to the presence of key players in the market along with increasing demand for mechanical seals in several industries such as manufacturing, oil & gas, and other mining industries. The growth is owed to deep involvement of workers with technology research and development (R&D) and STEM (science, technology, engineering, and mathematics) in the industries such as energy & power, oil & gas, and aerospace. Furthermore, the demand for the sealing products is accounted for increasing presence of manufacturing industries such as automotive and aerospace to energy industries such as oil and gas extraction to high-tech services such as computer software and computer system design, including health applications.

Furthermore, Europe is witnessing rapid growth owing to rising presence of chemical manufacturing industries along with growing use of sealing products in aerospace, rail, and marine industries. Additionally, demand for sealing products is comparatively stable as the large range of industries in the market offers a relatively balanced market growth over the years. The stability in demand can be seen in the period 2020-2024. Countries such as Italy and Spain are expected to show substantial growth compared to other countries in the region owing to the demand from major industries such as oil & gas and food & beverage.

The mechanical sealing market value in the Middle East and Africa is growing due to presence of more than 65% of global oil refineries in the region. Increasing investment in the oil industry will result in increased demand for mechanical seals. Moreover, countries of the Middle East are shifting their focus from oil and gas production to other industries such as tourism and other manufacturing industries which will result in decreasing market value of mechanical seals.

The manufacturing sector has declined in Latin America over the past few years owing to the decline in the production of cars and other equipment. Moreover, in 2015, the manufacturing production index of Latin America had declined by 0.9%, according to MAPI Foundation. The construction and oil and energy sub-segments are expected to grow at higher rate, owing to the increasing population and demand for the adoption of natural resources. Governments of Brazil, Mexico, and Argentina are working continuously on investing in green energy projects, which in turn will boost the adoption of mechanical seals in several different industries.

SKF (SKF AB), John Crane (Smiths Group Plc.), and Flowserve Corporation are the leading market players. SKF holds the largest market share, as per the mechanical seals market report. This is a result of SKF’s market understanding, along with demand forecasting, which is growing with customer-specific value propositions, giving the company an uptime for designing and production of mechanical seals. This fits with company’s existing engineering skills and asset management approach, with strategic focus on new technology providing value for money and digitalizing of the entire value chain.

Flowserve shares five unconsolidated joint ventures located in Latin America, Middle East, and Asia-Pacific regions, mainly in Saudi Arabia, India, The United Arab Emirates, South Korea, and two in China. The company has a portion of the products manufactured, assembled, or serviced in the territories. The joint venture has provided different strategic opportunities, including increased access to the potential markets, along with access to added manufacturing capacity and development of an efficient platform.

Furthermore, John Crane announced that it completed its purchase of the Engineering Division of Advanced Diamond Technologies. The acquisition of ADT will result in enhanced reliability and performance of mechanical seals in key settings in pumps along with other industrial equipment, bringing significant benefits to customers. Also, these strategies offer an enhanced product portfolio to their clients with minimum timelines.

The research report offers an in-depth analysis of the mechanical seals market. It further provides details on the adoption of mechanical seals products across several regions. Information on trends, drivers, opportunities, threats, and restraints of the market can further help stakeholders to gain valuable insights into the market. The report offers a detailed competitive landscape by presenting information on key players, along with their strategies, in the market.

March 2019:John Crane announced its new T4111 cartridge seal. The seal, called the Elastomer Bellows Cartridge Seal, is single-use and is designed to seal rotary and centrifugal pumps, along with similar rotating shaft machines.

April 2019:Dover announced the latest Air Mizer solutions design for the AM Conveyor Equipment Manufacturers Association shaft seal, which is explicitly developed for CEMA equipment & screw conveyors.

March 2018: Hallite Seals continued its third-party authentication with Milwaukee School of Engineering (MSOE) for the reliability & integrity of the design of its seals & sealing materials.

May 2017: Flowserve Corporation declared that it had completed the deal which involves sale of the Gestra AG unit to Spirax-Sarco Engineering plc. This sale was the part of Flowserve strategic decision to optimize its product range, enabling it to emphasis more on its core business activities and allowing it to be more competitive.

By 1954, mechanical seals were used with such regularity in the refining and process industries that the American Petroleum Institute included seal specifications in the first edition of its Standard 610, Centrifugal Pumps for General Refinery Services. Because of problems when converting from packing to seals, the seal specifications (just over one page in length!) were mostly concerned with stresses, bolting and gasketing. Glands were required to use a minimum of 4 bolts of at least 2 inch diameter and to have a nonferrous close clearance throttle bushing. In 1955, the American Standards Association attempted to standardize some pump dimensions and nomenclature. This work led to the American Voluntary Standard (AVS) pump which eventually became the ANSI pump.

By 1956, many of the conceptual designs and application guidelines that are in use today had been developed (Elonka, 1956). Commercially available designs included both rotating and stationary flexible elements, balanced and unbalanced hydraulic loading, rubber and metal bellows, and a wide variety of spring designs and types. Secondary sealing elements included O-rings, wedges, U‑cups and various packings. Carbon-graphite was widely used as a seal face material but the mating seal face was often cast iron, Ni-resist, 400 series stainless steel, Stellite or aluminum oxide ceramic although tungsten carbide was coming into use. Hard facings, especially Stellite, were often applied to stainless steel and used in process pump seals. When two hard faces were used, the carbon-graphite face was usually replaced with cast iron, bronze or sometimes tungsten carbide. Then, as now, stainless steel was widely used for springs, retainers, sleeves and glands. Temperature ratings for these seals were in the ranges of 200 to 800 F depending on design and materials. Pressure ratings were up to 1000 psig depending on design and materials. Single and multiple (called “double” and “tandem”) seal arrangements were used as necessary to accomplish the required performance. It is doubtless fair to say that the allowable leakage for mechanical seals in the 1950’s was significantly more than today. After all, in those days, leakage from seals was compared to leakage from packing and the mechanical seal was a definite improvement!

Karl Schoenherr, himself a major contributor to mechanical seal technology, credits Herbert B. Hummer, chief engineer of Durametallic, with the developing the pressure-velocity product (PV) as a guideline for design and application of mechanical seals (Schoenheer, 1995). Hummer’s work on PV began in the early 1950’s. In addition to PV, Hummer demonstrated the effects of shaft deflection on seal performance and developed guidelines for limits. Schoenherr, then Chief Engineer of John Crane, promoted the PV concept as well as published many articles on the basics of mechanical seals.

Metal bellows have been used as sealing elements in mechanical seals, valve stems and other equipment since 1950. In 1957, Sealol introduced the edge welded metal bellows seal. Previously, metal bellows seals had used a formed bellows which was much thicker and stiffer than the edge welded metal bellows. The early focus was on high temperature applications.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

ISO 9001:2015 certified. Custom manufacturer of abrasion, acid, alcohol, alkali, oxidation, ozone, radiation, sunlight and water resistant rubber and plastic O-ring seals. Made from EPDM, butyl, fluoroelastomer, fluorosilicone, natural rubber, neoprene, nitrile, NBR, HNBR, SBR, silicone, high tear strength silicone, TPR, TPU, TPE, thermoplastics and polyurethane. Capabilities include injection molding, die cutting and prototyping. Assembly and PTFE coating additional services are also provided. Serves the aerospace, automotive, commercial, construction, dental, electrical, food handling, laboratory, marine, mining, municipal, oil and gas, recreational, retail, transportation and wastewater industries. Meets ASTM and SAE standards. Six Sigma certified. JIT delivery. Overseas sourcing options also offered.

Amechanical seal is the most common type of sealing component used on pumps in modern industry. Replacing out packing over the last 50 or so years, they have served to drastically reduce industry emissions, energy usage and downtime globally.

A mechanical seal for pumps can be subdivided into variable options depending on the type/specific application/design components/location and mechanical seal characteristics;

The major advantage of a cartridge seal over a component seal is ease of installation. Incorrect installation is a major cause of seal failure, cartridge seals remove many of the problems associated with seal change-out in the field.

Slurry Seal – mechanical seal engineered to cope with a heavy slurry process – i.e. abrasive, corrosive and viscous. Can handle up to 60% slurrys by weight.

A Pusher Seal is where there is a spring element in the seal (used to maintain contact of the seal faces). Spring types include Belleville, multi-spring, etc. This type of seal requires a dynamic secondary seal.

A gas seal is a double seal where the barrier fluid is a gas – in pumps, this is usually a gas lift-off seal. In a gas lift-off seal the faces are not in contact while the machine is running. They are separated by a thin gas film (flow). If operated correctly they have very low wear.

The above seal types can be combined (though it is not always best to do so i.e. a component gas lift off seal would require very close collaboration between the machine and seal manufacturers to achieve a reliable installation).

There are many other options for mechanical seals, if you have any technical queries on other combinations not listed above, just contact one of our Mechanical Seal Specialists who will gladly discuss your application.

A mechanical seal flush is a piping set-up on a pump and seal assembly where a flow is induced in the seal chamber in order to improve MTBF of the mechanical seal. It is used to improve cooling, heating, remove solids and increase pressure (in combination with a neck or throat bush).

A mechanical seal quench is a piping set-up where a fluid is piped over the atmospheric side of a seal. It is generally used to prevent precipitation or crystallisation of a product or in some cases to aid cooling.

High Slurry process using Flowserve’s UNCD ® – Ultrananocrystalline diamond seal face technology. Flowserve UNCD ® coatings offer material properties and performance advancement over all other seal face materials.

Slurry seal design expertise applications which previously required double mechanical seals can now be reliably run by using single mechanical seals, saving costs of barrier fluid systems, the costs of the barrier fluid itself & the associated running costs. This reduces energy usage & carbon footprint.

If you have a technical query around the installation of mechanical seals for pumps or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running again.

8613371530291

8613371530291