flowserve mechanical seal parts brands

The use of the word “seal” is a misnomer; as a mechanical seal is a restrictive flow path,that is either an angular or radial gap.The flow through this gap is generally so low it goes unnoticed if a liquid or inconsequential if a gas.

A mechanical seal works byretaining a liquid or gas inside a rotating piece of equipment. Mechanical seals can be designed to prevent contamination of the process by the environment and prevention of leakage of the process into environment.

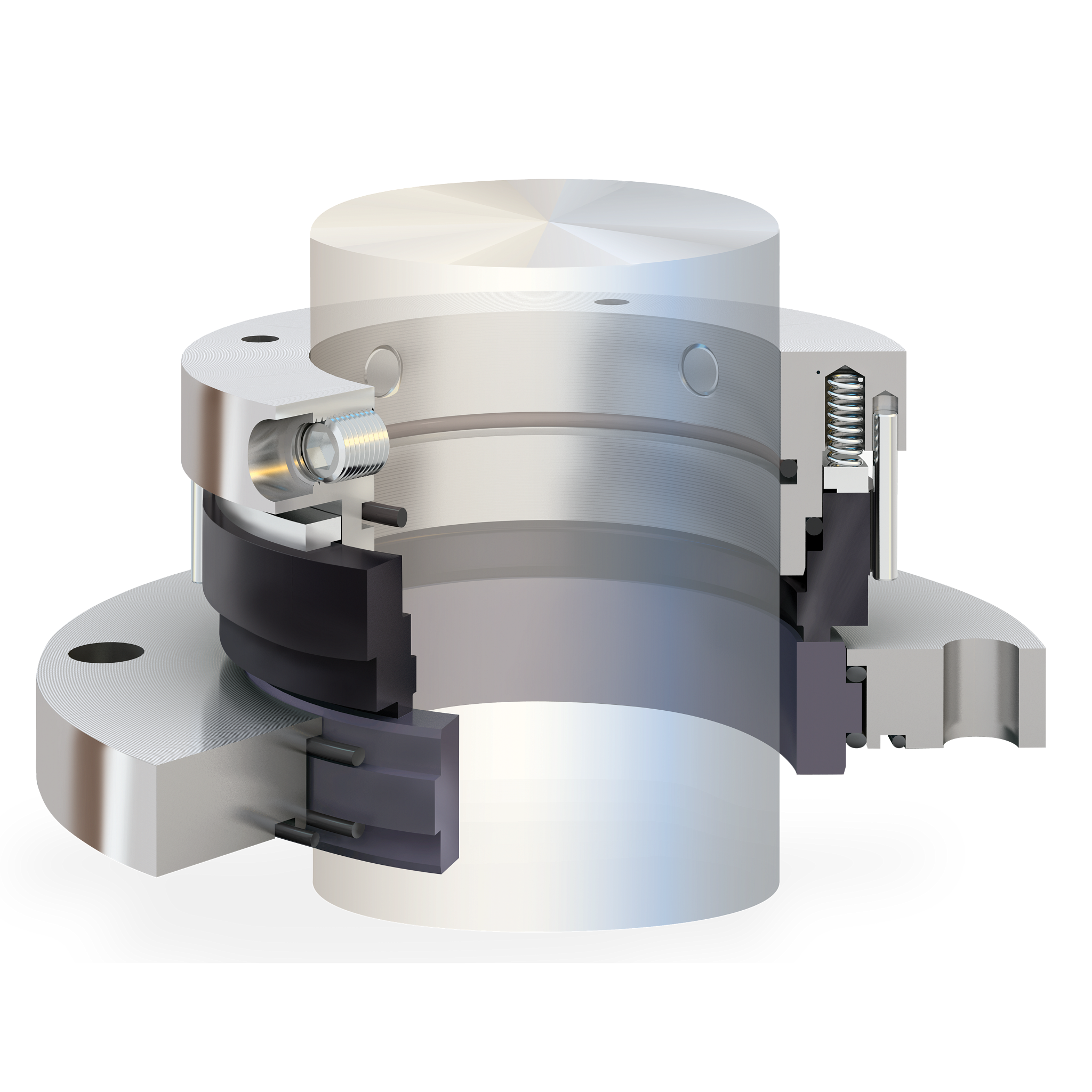

The basic components of a mechanical seal are a Rotating Part and a Stationary Part. The primary seal of a mechanical seal consists of a rotating face and a stationary face. The faces are kept lubricated by maintaining a thin film of fluid between each face. There is a very small gap between these 2 components which creates a restrictive flow path.

There are other components namely o-rings or gaskets which are used as secondary seals and hardware which is used to support the seal faces and to attach them to the rotating part (i.e shaft) and stationary part (i.e cover plate).

The primary seal of a mechanical seal is made up of 2 seal faces where these two parts meet is where the seal gap is located. The mating surface of the seal face is machined to a very tight tolerance.

Double Seal (Barrier) => consists of two primary seals in various arrangements. There is a barrier fluid between the two primary seals which is at a higher pressure than the process. There is always some leakage of the barrier fluid in process & out to atmosphere. As long as barrier pressure is maintained there is no leakage of process to atmosphere or contamination of process by environment.

Double Seal (Barrier) – Wet => is a double seal where the barrier is a liquid. It is generally the most robust seal. It has a good pressure, speed and temperature capabilities.

Gas Contacting Seal– the seal faces are in contact, the soft face wear acts as a lubricant. Low pressure, speed and temperature capabilities and possibilities of wear getting into the process.

Gas Non Contacting Seal – the seal faces are NOT in contact. They are kept apart by a flow of gas between the faces. Good temperature, speed and pressure capabilities. If operated correctly their is no wear but care must be taken in order to minimise shaft run out.

Cartridge seal =>is where the rotating and the stationary hardware are pre-assembled before mounting onto the pump/mixer. Cartridge seals are much easier to fit & maintain compared to the component seal.

A lip seal is a specific type of seal, it is a radial seal, where the part that seals against the rotating surface is a narrow cross section, soft material i.e the lip and it is made from an elastomer or non-elastomer material with a backup spring. Most commonly used to seal bearings in Mixers/Agitators. A lip seal rotates too quickly to be used on pumps.

Abarrier fluid is any gas or liquid which is used to pressurise a double mechanical seal. It must be compatible with the process, generally non-toxic and a good lubricant.

Please consult the pump manufacturer/distributor for guidance on these calculations for mixer seals, the barrier pressure is set at a certain value above the maximum vessel pressure.

Packing is a material that is stuffed between a rotating shaft and a stationary part gland to maintain pressure. Packing is a low cost alternative to mechanical seals.

We supply mechanical seals into the pharmaceutical, bio-technology, chemical processing, mineral and ore processing, semi-conductor and general industries.

Depending on your particular application, if you are looking mechanical seals to suit a pump application; Mechanical Seal for Pumps, or if you are trying to source mechanical seals for an agitator or tank mixer; Mechanical Seal for Agitator, or perhaps you have a hygienic application in mind, take a look at our range of Mechanical seal for Hygienic & Aseptic applications.

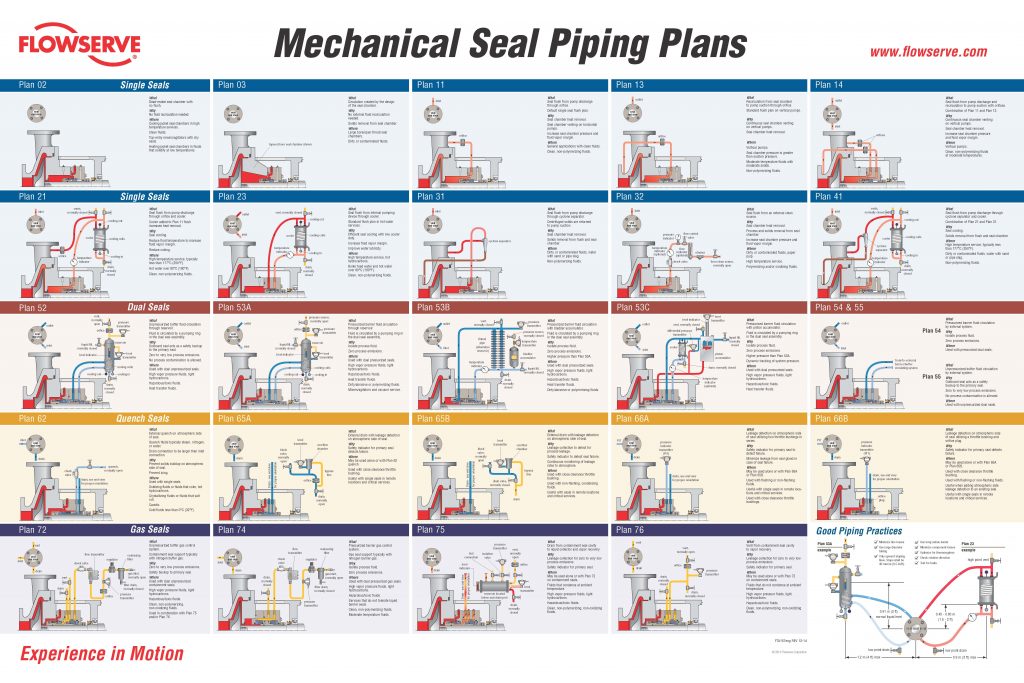

Our Mechanical Seal specialists can advise you on the appropriate selection of a seal support system which will deliver years of reliable service and operating cost savings in the longer term.

If you have any query around how to install mechanical seals or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running reliably again.

We provide expert Mechanical Seal Repair of all major brands, including John Crane®, Flowserve®, Burgmann®, and more. With locations in Gonzales, LA, and Williston, VT, we are the reliable, convenient single source repair for all styles of mechanical seals.

Our comprehensive library of manufactured design solutions addresses applications in the field and pump-specific challenges providing upgrades and replacement seals manufactured to perform better and last longer.

Flexaseal’s experienced maintenance and repair technicians have worked with mechanical seals from the world"s largest pump and seal manufacturers, including John Crane® and Flowserve®. Below is just a sampling of the many manufacturers and styles that we have repaired. If your seal isn’t listed, just click “Request A Quote” to send us a message.

Each repair that comes to our repair departments in Louisiana or Vermont - whether it is a third-party design or a Flexaseal model - goes through a detailed, 5-step process to ensure customer satisfaction.

Flexaseal offers repair kits for on-site seal repair. These kits are specific to your Flexaseal cartridge and are a great way to have parts on hand for an emergency situation. All items in the kit are packaged and labeled to ensure efficient change-out.

Every mixer, agitator, and reactor model is distinctive and engineered for specific applications. When repairing a mixer seal, Flexaseal evaluates the conditions in which the seal operates. This evaluation ensures we are repairing your seal to your parameters.

Sometimes a failed seal is no longer a candidate for repair. Flexaseal provides straightforward solutions from our comprehensive seal lines or upgraded options designed for your unique operating environment.

The Flexaseal Gulf South location is a fully functional, self-sufficient mechanical seal repair and service facility for mechanical seals. Our Southern U.S. shop - located between Baton Rouge and New Orleans in Gonzales, LA - is a brand new 5,000 square foot, state-of-the-art facility ready for your mechanical seal repair and service needs.

Machining Capabilities – Our Gulf Coast technicians have extensive knowledge and machining experience. These skills enable the team to quickly and efficiently process seal repairs, getting your equipment back into operation with minimal interruption.

Stocking Location – The Gonzales store front has a range of Flexaseal sealing products for immediate off-the-shelf delivery. We are also an assembly and stocking location forseal support systems including barrier fluid reservoirs.

If you are in need of an ASI©seal replacement, Gaddis Mechanical Seals is here to help. We offer replacement mechanical seals for a variety of applications, and our team is highly experienced in mechanical seal repair and installation. We understand the importance of keeping your machinery running smoothly, and we will work diligently to get your mechanical seals repaired or replaced as quickly as possible. With ASI© Mechanical Seals, you can rest assured that your mechanical seal repair needs will be handled promptly and professionally. Contact us today to learn more about our mechanical seal repair services.

The welded metal bellow seals products make use of the durability, pressure resistance and uniform displacement include bellows seals and vacuum bellows in semiconductor or electronic parts manufacturing facilities, and have earned a reputation for high performance.

8613371530291

8613371530291