how does a mechanical seal work quotation

Mechanical seals form a critical part of any mechanical operation involving fluid movement through rotational shafts, such as in the case of pumps. These seals ensure that the fluid does not leak out of a closed system and contaminants do not enter the system. In pumping applications, mechanical seals are placed at the point of entry or exit of a rotating shaft, preventing the pressurized fluid from escaping the pump housing and withstanding the friction generated from the shaft rotations.

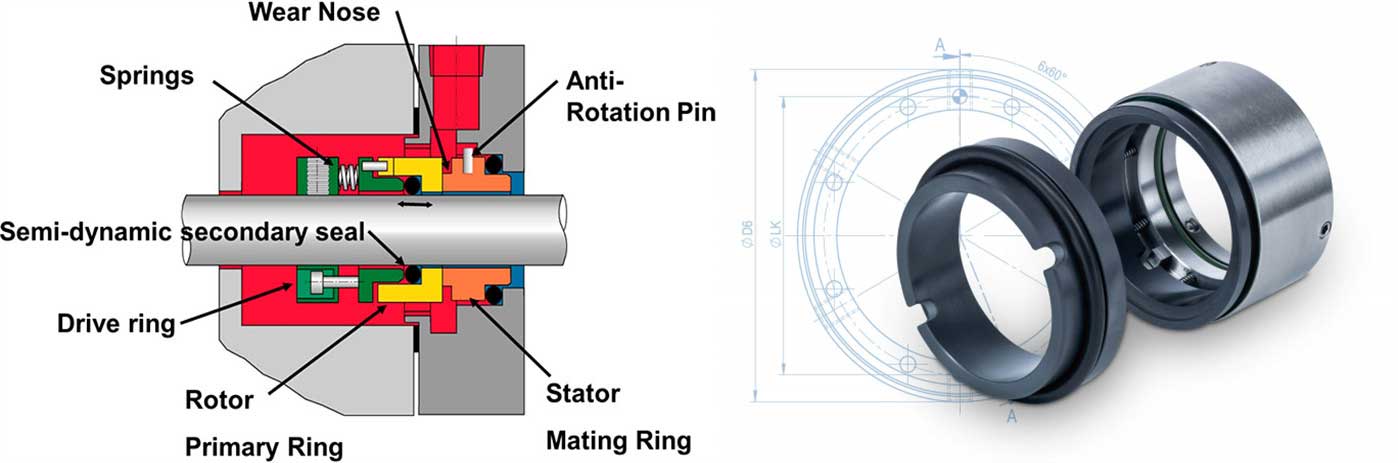

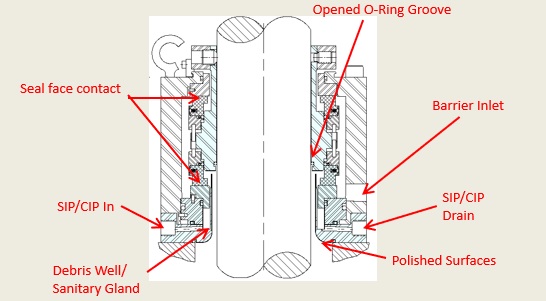

Mechanical seals are devices that accommodate a rotating shaft while containing and preventing the fluid from leaking out of the enclosed housing. While different mechanical seal designs are available for pumping applications, most have three sealing points.

These three sealing points ensure that the fluid contained within the pump housing does not leak while also preventing dust particles in the atmosphere from entering the housing.The mechanical seals are usually made up of different materials to prevent sticking. Typically, one side of the seal uses softer materials like carbon graphite, and the other is made of harder materials such as silicon carbide or ceramic alumina. However, hard materials are preferred for both surfaces if the pumping application involves abrasive fluids.

In addition to the two materials, the sealing unit also comes with O-rings to seal the stationary face on the housing side and the rotating face on the shaft side. Springs are also used to keep both faces pressed.

In most cases, the two faces of the seals are also lubricated to prevent friction and wear. Depending on the application, this fluid film can either be a separate lubricant or the process fluid itself.

Mechanical seals can be selected based on the type of pump application. Choosing the wrong seal can affect pump performance and lead to damage and costly repairs.An unbalanced mechanical seal is preferred if the pump needs to operate at a lower pressure. However, high pressure pumping applications require balanced mechanical seals. Balanced seals also perform better in high temperature operating conditions. Cartridge seals require less maintenance but are more expensive, hence used for limited applications.

At Hayes Pump, we have a fully staffed, factory-trained parts department to help you quickly with the correct mechanical seal for your pump. You canrequest a quotefor your part orcontact usto get further assistance.

Mechanical seals are designed to prevent leakage of fluid from centrifugal pumps that support industrial processes. Mechanical seals depend on mechanical seal support systems for reliable operations. I’ve provided information below to help explain mechanical seal support basics. I’m hopeful it’ll help you gain a better understanding of mechanical seals and the various types of mechanical seal support systems, their applications, and optional configurations to help boost reliability in your Northern California Bay Area refinery.

A mechanical seal is used to contain fluid within a centrifugal pump where the impeller shaft passes through a stationary housing. There’s a range of mechanical seal designs to cover every conceivable pumping process. Low to high pressure, low to high fluid temperatures, clean plant water to heavy hydrocarbons. To cover that wide range of pumping processes and conditions there’s an equally wide range of seal support systems and custom configurations to match the need.

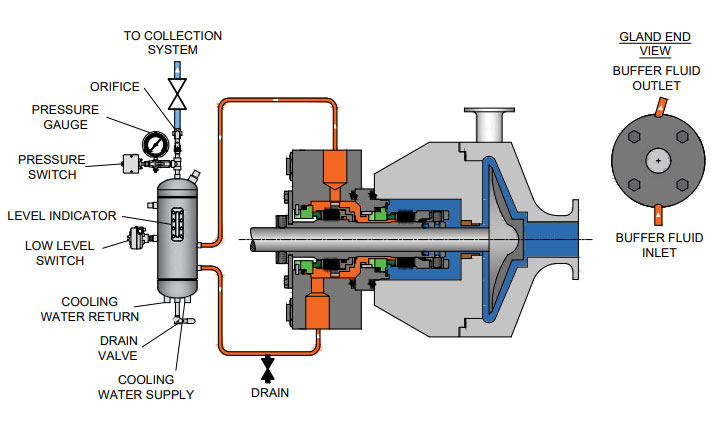

At its simplest, a mechanical seal support system is designed to provide the proper seal chamber environment to maintain the integrity of the mechanical seal. The system provides cooling and lubrication to reduce mechanical seal friction and heat and prevent leakage. To accomplish this, mechanical seal support systems deliver process fluid, water, oil, or inert gas to the seal chamber at the required pressure, temperature, and flow.

Maintaining the proper seal chamber environment prevents leakage that could lead to loss of profitable products, degradation of pumps and their supporting infrastructure, or in the worst cases, conditions that pose environmental risk and subject you to Cal/OSHA and BAAQMD sanctions.

Centrifugal pumps and mechanical seal support systems are critical to the petroleum industry. As a result, the American Petroleum Institute has developed a standard to describe the different seal support systems, known as piping plans. See API Standard 682: Pumps—Shaft Sealing Systems for Centrifugal and Rotary Pumps for a listing of the various plans. The complete document is over 250 pages, but below I"ve distilled the document into a greatly simplified overview of mechanical seal support basics.

Mechanical seal support systems can be grouped into three categories—process side, dual or in-between, and atmospheric side. Let me explain the basics of these categories by describing the type of mechanical seal, the typical pumping applications, and the various API plans that provide the required environment for the mechanical seal and pumping conditions.

Process side mechanical seal support systems provide the lubrication and cooling to a single mechanical seal to keep process fluid within the pump volute. Process fluid is used for lubrication and cooling in three ways: it is circulated from the discharge to seal chamber, from the seal chamber to the suction, or from discharge to seal chamber and then to suction. Alternatively, a flush fluid that provides lubrication and cooling can be delivered from a reservoir which is part of the seal support system or an external source, such as plant water.

This single-seal solution is used when the pumped fluid poses no environmental threat in the event that the pumped fluid vaporizes as it crosses the seal faces and dissipates into the atmosphere. The table below summarizes the API Plans in the process side category, indicates the types of fluids used to provide cooling and lubrication, and the components that differentiate the plans and their capabilities.

Process side mechanical seal support systems cover a range of pumping processes, from clean, moderate-temperature, non-polymerizing fluids to high-temperature dirty or contaminated fluids. Cooling and filtering options enable these plans to remove contaminants that would damage seal faces. Pumping applications can include:

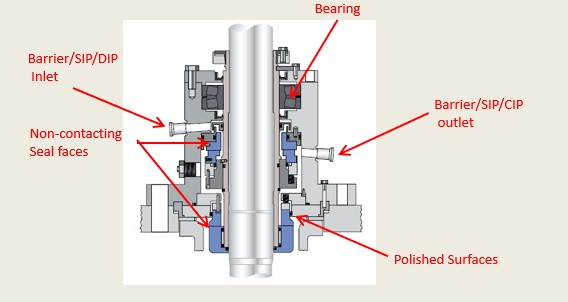

Dual or in-between mechanical seal support systems deliver a buffer (unpressurized) or barrier (pressurized) fluid to a seal chamber that contains a double mechanical seal—two seals arranged in series to maintain the buffer/barrier fluid between the two seals. The inboard (primary seal) keeps process fluid within the pump housing. The outboard (secondary seal) prevents the buffer/barrier fluid from leaking to the atmosphere. The buffer/barrier fluids that lubricate the seal faces and dissipate heat can be gas or liquid.

Pressurization of barrier fluid is provided by plant nitrogen, bladder accumulator, piston accumulator for API Plans 53A, 53B, and 53C respectively. Plan 54 is pressurized by the external pump. Plan 72 buffer fluid is plant nitrogen.

Atmospheric side mechanical seal support systems deliver an unpressurized fluid (also known as a “quench”) to the atmospheric side (exposed to air) of a mechanical seal. This method is used when a single mechanical seal cannot operate properly without the aid of the quench. In comparison to the process side and dual seal support systems, there are only two variants:

API Plan 62 - Quench From External Source delivers clean water, low-pressure steam, or nitrogen to cool the seal faces and prevent oxidation or coking of process fluid.

Our brief explanation of mechanical seal support system basics shows you the wide range of capabilities and applications. There’s a solution for every type of pumping process. You don’t need an in-depth understanding to obtain the maximum benefit from a mechanical seal support system if you work with a local vendor in the Northern California Bay Area who has deep industry experience.

In addition to knowing which mechanical seal support system is best for a specific pumping process, a local vendor who conducts an on-site evaluation is able to make specific recommendations regarding system design, instrumentation, and components to boost pump reliability. Fabricated and thoroughly tested in Swagelok’s Fremont, Santa Clara, or Concord facility, you’ll have a mechanical seal support solution custom-configured to the specific requirements of your pumping process.

Swagelok Northern Californiawill be happy to explain mechanical seal support basics and advise you on the specific plans to improve pump reliability. To arrange an on-site consultation by one of our Field Engineerscontact our teamtoday by calling

Mechanical seals prevent leaks of the pumped fluid and the loss of expensive pumped products. They keep or seal the pump so that the fluid stays inside it. Since about the 1950s, mechanical seals have almost completely eliminated the inefficient and expensive stuffing box.

They are installed where the pump shaft enters or leaves the pump housing. Seals of various types, sizes, and configurations are available. However, they all use the basic principle of a combination of fixed and rotating surfaces.

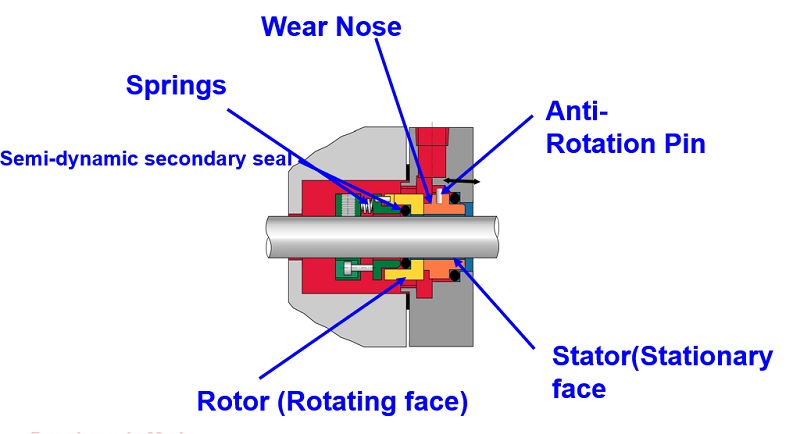

The mechanical seal works by using two very flat overlapping surfaces, which makes leakage difficult to occur. One surface does not rotate with the axis (stationary), while the second surface rotates with the axis (rotates).

When the two faces rub together, the fluid film between the two faces migrates for cooling and lubrication purposes. Ideally, the pumped fluid will flow out between the two faces, enter as a liquid, and evaporate when it reaches the atmosphere.

It must be pointed out at this point that all mechanical seals leak some very small amounts of steam, so even the best mechanical seal design will lose a small part of the pumped fluid.

Generally, there are various types of mechanical seals. According to design and layout, mechanical seals are generally divided into the following categories:

Mechanical seal can be divided into the internal seal, external seal, push-in seal, Non-push seal and Balanced seal. Here are the details of each type of mechanical seal.

The design of the internal seal is that the rotating part of the mechanical seal is located in the pump seal cavity. For internal seals, fluid and pressure are applied to the outer diameter (outer diameter) of the seal. Generally, internal seals are used for higher pressure applications compared to external seals.

The design of the external seal is that the rotating part of the mechanical seal is located outside the pump seal cavity. Normally, external seals are used for chemical applications of non-metal parts: the pumped fluid does not come into contact with the sealed metal parts, so expensive and/or special materials are usually not required.

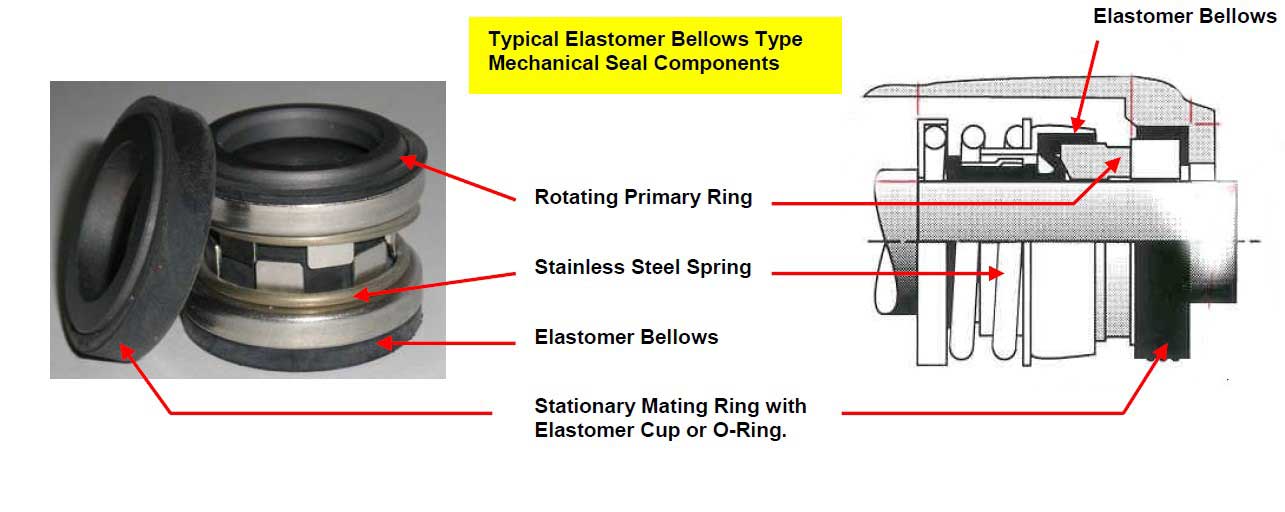

Push-in seal is a design that pushes a dynamic secondary seal (o-ring, wedge or other type of equipment) through the shaft as a means of compensating for surface wear and/or shaft movement.

In a balanced seal, the hydraulic pressure used to close the sealing surface is significantly reduced. The advantage of a balanced seal is that less heat is generated because the pressure is reduced to force the surfaces together. Therefore, they can withstand higher pressures than unbalanced seals.

Mechanical seals act without any reduction on the full hydraulic pressure present in the seal chamber in unbalanced seals. In low-pressure applications, unbalanced seals are the best choice.

Double seal: In this structure, two (2) mechanical seals are used face to face, back to back or in series (facing the same direction), thereby allowing buffer fluid or gas to be introduced between the two sets of sealing surfaces. Double seals are mainly used to seal volatile organic compounds, dirty, non-lubricated or very viscous products. In addition, they are also used for products that are cured or changed state.

The use of the word “seal” is a misnomer; as a mechanical seal is a restrictive flow path,that is either an angular or radial gap.The flow through this gap is generally so low it goes unnoticed if a liquid or inconsequential if a gas.

A mechanical seal works byretaining a liquid or gas inside a rotating piece of equipment. Mechanical seals can be designed to prevent contamination of the process by the environment and prevention of leakage of the process into environment.

The basic components of a mechanical seal are a Rotating Part and a Stationary Part. The primary seal of a mechanical seal consists of a rotating face and a stationary face. The faces are kept lubricated by maintaining a thin film of fluid between each face. There is a very small gap between these 2 components which creates a restrictive flow path.

There are other components namely o-rings or gaskets which are used as secondary seals and hardware which is used to support the seal faces and to attach them to the rotating part (i.e shaft) and stationary part (i.e cover plate).

The primary seal of a mechanical seal is made up of 2 seal faces where these two parts meet is where the seal gap is located. The mating surface of the seal face is machined to a very tight tolerance.

Double Seal (Barrier) => consists of two primary seals in various arrangements. There is a barrier fluid between the two primary seals which is at a higher pressure than the process. There is always some leakage of the barrier fluid in process & out to atmosphere. As long as barrier pressure is maintained there is no leakage of process to atmosphere or contamination of process by environment.

Double Seal (Barrier) – Wet => is a double seal where the barrier is a liquid. It is generally the most robust seal. It has a good pressure, speed and temperature capabilities.

Gas Contacting Seal– the seal faces are in contact, the soft face wear acts as a lubricant. Low pressure, speed and temperature capabilities and possibilities of wear getting into the process.

Gas Non Contacting Seal – the seal faces are NOT in contact. They are kept apart by a flow of gas between the faces. Good temperature, speed and pressure capabilities. If operated correctly their is no wear but care must be taken in order to minimise shaft run out.

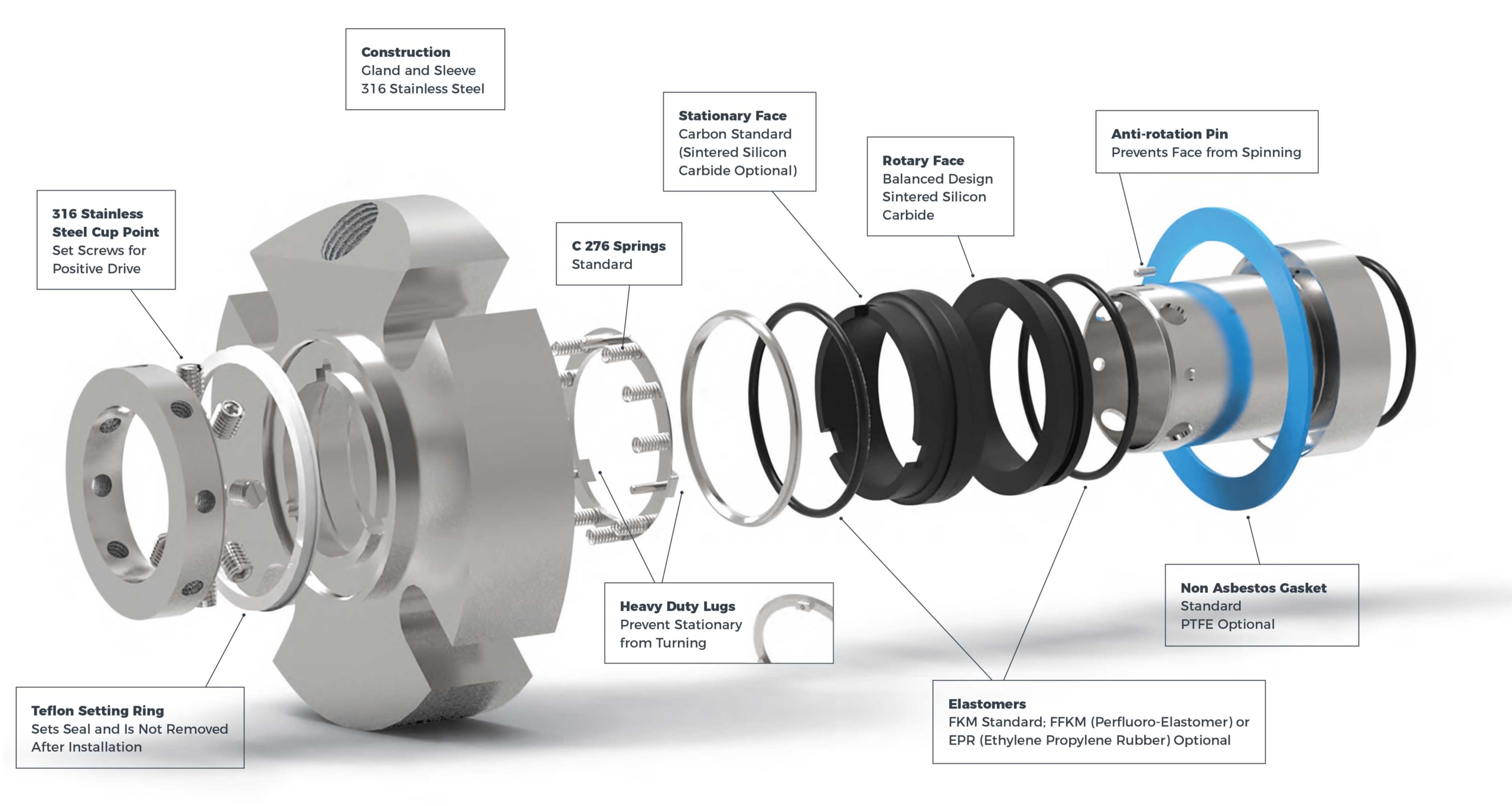

Cartridge seal =>is where the rotating and the stationary hardware are pre-assembled before mounting onto the pump/mixer. Cartridge seals are much easier to fit & maintain compared to the component seal.

A lip seal is a specific type of seal, it is a radial seal, where the part that seals against the rotating surface is a narrow cross section, soft material i.e the lip and it is made from an elastomer or non-elastomer material with a backup spring. Most commonly used to seal bearings in Mixers/Agitators. A lip seal rotates too quickly to be used on pumps.

Abarrier fluid is any gas or liquid which is used to pressurise a double mechanical seal. It must be compatible with the process, generally non-toxic and a good lubricant.

Please consult the pump manufacturer/distributor for guidance on these calculations for mixer seals, the barrier pressure is set at a certain value above the maximum vessel pressure.

Packing is a material that is stuffed between a rotating shaft and a stationary part gland to maintain pressure. Packing is a low cost alternative to mechanical seals.

We supply mechanical seals into the pharmaceutical, bio-technology, chemical processing, mineral and ore processing, semi-conductor and general industries.

Depending on your particular application, if you are looking mechanical seals to suit a pump application; Mechanical Seal for Pumps, or if you are trying to source mechanical seals for an agitator or tank mixer; Mechanical Seal for Agitator, or perhaps you have a hygienic application in mind, take a look at our range of Mechanical seal for Hygienic & Aseptic applications.

Our Mechanical Seal specialists can advise you on the appropriate selection of a seal support system which will deliver years of reliable service and operating cost savings in the longer term.

If you have any query around how to install mechanical seals or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running reliably again.

The mechanical seal is one of the most important components of a pumping system. As the name suggests, the seal is a simple component that forms a barrier between the motor and the volute of a pump, protecting the motor against leakage.

Leakage is death to any mechanical instruments and pumps are no exception. Fluid leakage often results in corrosion of the casings, sleeves and bearings. Corrosion left unattended over a period of time will will degrade the construction material of the pump. Fluid leakage that enters the motor shaft can short circuit the motor.

Naturally, these problems will impede proper pump functioning and eventually could stop the pump from running altogether. Companies often spend a lot in terms of money, wasted manpower and lost operational time to fix leakage.The mechanical seal is designed to prevent that leakage from ever happening. Mechanical seal shaft failure is the number one cause of pump downtime according to WaterWorld magazine.

Submersible wastewater pumps, such as sewage pumps, are particularly susceptible to the dangers of leakage as their operation depends on being surrounded by water that may contain potentially corrosive or clogging waste solids. This water can accumulate in the motor casing and obviously a submersible pump cannot be drained without interrupting operation.

A wide variety of seal types are available for any number of applications. The type of seal most commonly used in sewage pumps is an end face mechanical seal.

In an end-faced seal two ringed “faces” or seal heads rest flat against each other (but are not attached) in the seal chamber, which is located between the volute (the “wet end” of the pump) and the motor. An actuator, such as a spring, presses the faces close to each other.

The rotating motor is inserted through the two ringed faces and attached to the impeller. As the motor shaft rotates, the upper seal (closer to the motor) rotates with the shaft. The bottom seal closer to the volute remains stationary.

This action creates a sealing interface which keeps the water in the volute and prevents leakage. A minimal amount of water might escape the sealing interface but this liquid essentially acts as a lubricant for the seal and will eventually evaporate from heat.

All the components of an end faced mechanical seal work in unison to prevent leakage and are equally important to proper functioning. The main components are:

1. The primary seal faces that rest against each other. The primary seal faces are typically made of durable materials such as silicon carbide, ceramic carbide or tungsten. Certain materials work better for certain applications. For instance, silicon carbide is resistant to acidic liquids, less so to alkaline liquids. Generally, face materials should be of high hardness and should have the ability to slide on each other.

2. Secondary seal surfaces or faces. The secondary faces surround the primary seal faces, but do not rotate. The secondary surfaces hold the primary faces in place and create an additional barrier. Secondary faces can come in a variety of forms – examples include o-rings, elastomers, diaphragms, mating rings, gaskets and wedges. The secondary face also allows for shaft deflection and misalignment.

3. Actuator or a means of pressing the seal faces together and keeping the entire seal properly aligned to the shaft. Often (but not always) a loaded spring. The actuator is mounted above the seal face closer to the motor while the motor shaft passes through the spring.

Mechanical seals are precise, sensitive and temperamental instruments. Even seemingly minor mishandling can negate the seal’s functionality. Therefore Pump Products highly recommends leaving the mounting and installation of mechanical seals to qualified technicians.

Before you actually handle your mechanical seal, be sure to wash your hands thoroughly. Because the faces are meant to be extremely flat, even small particles from the oil of human hands can damage the surface integrity of the faces and render the seal useless. Make sure to wipe the seal itself with an alcohol solution, in case another person touched the seal faces during the packing or shipping process.

The following is a basic guide to replacing a defective mechanical seal. Each seal should come with its own specific instructions, but this is overview covers the most essential parts of the mounting process.

2. Carefully remove the old seal head, taking care not to scratch the motor shaft. Take note of how the seal was mounted; the new seal will be mounted in the same manner.

Mechanical seals are classified by construction type and the construction type is expressed through a letter code. The seal listing code will designate the construction material of each component. For example, here is a construction code guide from U.S. Seal:

The construction materials of the seal will in turn inform what specific seal is suited for your specific pumping application. You can consult a material recommendation chart to best choose the right mechanical seal.

The above chart is a guide to identifying and sizing the appropriate mechanical seal for your pump. Because seals are specifically engineered instruments, making sure that the seal is properly sized for a specific pumping system and application is critical. Manufacturers often make specific recommendations for the type of material to use for an application as well – a recommendation chartis helpful.

Seals are used to keep liquids and gases from entering certain areas or mixing with one another. A mechanical seal is a type of seal that uses mechanical pressure to seal a certain area or equipment.

A plug is jammed into an opening to keep any liquids or gases from entering. The mechanical pressure with which the plug is forced into an opening causes complete sealing. One of the earliest and simplesttypes of seals, plugs are used in wine bottles. A gasket is similar to a plug in function. It uses mechanical pressure to provide sealing properties. The difference lies in the material being used. A gasket is made of a spongy material. This helps in providing a surer seal. If two pipes or devices being sealed are not properly aligned, or slightly differ in size, this seal is able to fit into both and provide a better seal. It helps in sealing as well as joining the two misaligned parts.

A hose coupling is fitted at the end of a hose, which connects to the water source. Hose couplings are fit on tightly at the end of a pipe. This creates a very tight seal, which doesn’t allow any water to escape.

Some seals use both pressure as well as tight fit to provide efficient sealing. Shafts are a kind of complex mechanical seal that fit tightly in their casing. There is a layer of oil where they meet. A gasket is also inserted between the casing and the shaft. All of this together helps in keeping the water from entering the seal.

Mechanical seals are used in a variety of applications to keep various liquids, gases, and dirt from entering specific parts of an application. They prevent contamination and increase operational efficiency of a unit.

Seals are a simple method of preventing fluid from escaping a vessel. Equipment like centrifugal pumps rely on seals to contain large volumes of pressurized fluid. There are two types of seals: the traditional pump packing known as mechanical packing or gland packing and the more modern mechanical seal. Mechanical packings rely on a rope-like packing, cut into rings, that wraps around the shaft of a pump to fill the voids and throttle or control the fluid from leaking.

Mechanical seals are often preferred when leakage is unacceptable, such as applications involving hazardous materials. Their durable construction can withstand more wear and tear than mechanical packing without leaking. We will explain how pump sealing works and describe the differences between pump packing versus mechanical seals to help you determine the best solution for your application.

Mechanical seals consist of three sealing components: rotating, stationary, and secondary seals. The seals prevent leaks from the circumferential gap between the shaft and other pump components. The rotating and stationary seals are lapped flat to keep fluid and gas from escaping. The rotating primary sealing element, fastened to the shaft, seals against the primary stationary sealing element, normally fastened to the gland.

Secondary seals are usually mounted between the stationary unit and the pump housing, and between the rotating unit and the pump shaft or sleeve. These are static seals, normally O-rings, PTFE wedges, or V-rings, and prevent leakage through these elements.

The rotating and stationary primary seals are the most vital sealing points. The faces of the mechanical seals press together with the force of a spring. In some cases, mechanical seals can also come as hydraulically balanced, in which case the fluid takes over from spring pressure to keep faces together while the pump is running. To make the mating surface as flat as possible, surfaces are lapped flat and machinists use high-precision light-band optical flats to ensure accuracy.

Protect Fluid Products From Leakage: Eliminates leaking common in packing. Leakage from packing is common compared to mechanical seals and can waste significant product.

Eliminates Sleeve Wear: Reliability of the seals eliminates frequent maintenance and removal of the sleeve that can result in costly sleeve replacement.

Cartridge Seals: Combines seal components, gland, and shaft sleeve into a single cartridge. They facilitate normally easier installation with preset face loading and quicker removal from pump shafts.

At MPRC Seals, we have been delivering reliable seals since 1982. We find solutions to the most difficult sealing issues for customers in a range of industries. To learn more about our customer-focused sealing solutions, request a quote today.

Thankyou for posting this informative article, I was looking for a little information on Mechanical seals as I wanted to buy them for my project. This article helped alot.

A mechanical seal is simply a method of containing fluid within a vessel (typically pumps, mixers, etc.) where a rotating shaft passes through a stationary housing or occasionally, where the housing rotates around the shaft.

When sealing a centrifugal pump, the challenge is to allow a rotating shaft to enter the ‘wet’ area of the pump, without allowing large volumes of pressurized fluid to escape.

To address this challenge there needs to be a seal between the shaft and the pump housing that can contain the pressure of the process being pumped and withstand the friction caused by the shaft rotating.

Before examining how mechanical seals function it is important to understand other methods of forming this seal. One such method still widely used is Gland Packing.

Packing needs to press against the shaft in order to reduce leakage – this means that the pump needs more drive power to turn the shaft, wasting energy.

The stationary part of the seal is fitted to the pump housing with a static seal –this may be sealed with an o-ring or gasket clamped between the stationary part and the pump housing.

The rotary portion of the seal is sealed onto the shaft usually with an O ring. This sealing point can also be regarded as static as this part of the seal rotates with the shaft.

One part of the seal, either to static or rotary portion, is always resiliently mounted and spring loaded to accommodate any small shaft deflections, shaft movement due to bearing tolerances and out-of-perpendicular alignment due to manufacturing tolerances.

The primary seal is essentially a spring loaded vertical bearing - consisting of two extremely flat faces, one fixed, one rotating, running against each other. The seal faces are pushed together using a combination of hydraulic force from the sealed fluid and spring force from the seal design. In this way a seal is formed to prevent process leaking between the rotating (shaft) and stationary areas of the pump.

If the seal faces rotated against each other without some form of lubrication they would wear and quickly fail due to face friction and heat generation. For this reason some form of lubrication is required between the rotary and stationary seal face; this is known as the fluid film

In most mechanical seals the faces are kept lubricated by maintaining a thin film of fluid between the seal faces. This film can either come from the process fluid being pumped or from an external source.

The need for a fluid film between the faces presents a design challenge – allowing sufficient lubricant to flow between the seal faces without the seal leaking an unacceptable amount of process fluid, or allowing contaminants in between the faces that could damage the seal itself.

This is achieved by maintaining a precise gap between the faces that is large enough to allow in a small amounts of clean lubricating liquid but small enough to prevent contaminants from entering the gap between the seal faces.

The gap between the faces on a typical seal is as little as 1 micron – 75 times narrower than a human hair. Because the gap is so tiny, particles that would otherwise damage the seal faces are unable to enter, and the amount of liquid that leaks through this space is so small that it appears as vapor – around ½ a teaspoon a day on a typical application.

This micro-gap is maintained using springs and hydraulic force to push the seal faces together, while the pressure of the liquid between the faces (the fluid film) acts to push them apart.

Without the pressure pushing them apart the two seal faces would be in full contact, this is known as dry running and would lead to rapid seal failure.

Without the process pressure (and the force of the springs) pushing the faces together the seal faces would separate too far, and allow fluid to leak out.

Mechanical seal engineering focuses on increasing the longevity of the primary seal faces by ensuring a high quality of lubricating fluid, and by selecting appropriate seal face materials for the process being pumped.

When we talk about leakage we are referring to visible leakage of the seal. This is because as detailed above, a very thin fluid film holds the two seal faces apart from each other. By maintaining a micro-gap a leak path is created making it impossible for a mechanical seal to be totally leak free. What we can say, however, is that unlike gland packing, the amount of leakage on a mechanical seal should be so low as to be visually undetectable.

**Please note: There are many things to evaluate when selecting a seal, so be sure to speak with an experienced engineer before your final selection is made.

Identifying the exact liquid being handled is the first step in the seal selection process. Seal material must be able to withstand the fluid being processed. All seal materials must be chemically compatible with the fluid, or there is an increased risk of seal failure.

Seal materials must be selected to appropriately handle the liquid’s temperature. Temperature is important because different seal materials are rated for certain termperatures and you should not exceed the temperature limit of these materials.

Knowing the viscosity of the liquid is important to ensure appropriate seal life. Abrasive liquids can create excessive wear and will ultimately shorten the seal"s life. Double seals or use of an external flush plan give operator"s the option to use mechanical seals on these difficult fluids.

Every company has their own standards and operating procedures when it comes to reliability and emission concerns for an application. The seal type and arrangement selected must meet the desired reliability and emission standards for the pump application. Since environmental safety has become a hot topic among manufacturing companies, double seals are peaking as the solution of choice.

After understanding the seal"s exact operating conditions, you can select the seal"s overall construction material and its face and component materials. When selecting the seal"s material of construction, be sure to consider the following characterstics of the material:

As you work with your local seal supplier, remember that a mechanical seal recommendation is not complete without a seal support plan, such as a seal flush piping plan. And, if you are new to mechanical seals and are considering making the switch from packing to the mechanical seal, read more about it on our blog, Understanding the Basics of Mechanical Seals vs. Packing.

Mechanical seals are devices that seal machines between rotating parts (shafts) and stationary parts (pump housing) and are an integral part to the pump. Their main job is to prevent the pumped product from leaking into the environment and are manufactured as single or double seals. What"s the difference between the two?

A single mechanical seal consists of two very flat surfaces that are pressed together by a spring and slide against each other. Between these two surfaces is a fluid film generated by the pumped product. This fluid film prevents the mechanical seal from touching the stationary ring. An absence of this fluid film (dry running of the pump) results in frictional heat and ultimate destruction of the mechanical seal.

Mechanical seals tend to leak a vapor from the high pressure side to the low pressure side. This fluid lubricates the seal faces and absorbs the heat generated from the associated friction, which crosses the seal faces as a liquid and vaporizes into the atmosphere. So, it"s common practice to use a single mechanical seal if the pumped product poses little to no risk to the environment.

A double mechanical seal consists of two seals arranged in a series. The inboard, or “primary seal” keeps the product contained within the pump housing. The outboard, or “secondary seal” prevents the flush liquid from leaking into the atmosphere.

Two rotating seal rings are arranged facing away from each other. The lubricating film is generated by the barrier fluid. This arrangement is commonly found in the chemical industry. In case of leakage, the barrier liquid penetrates the product.

The spring loaded rotary seal faces are arranged face to face and slide from the opposite direction to one or two stationary seal parts. This is a popular choice for the food industry, particularly for products which tend to stick. In case of leakage, the barrier liquid penetrates the product. If the product is considered “hot”, the barrier liquid acts as a cooling agent for the mechanical seal.

Are you still using packing for your pumps? Read about the differences between packing and mechanical seals to see if switching to mechanical seals makes sense for your plant. A qualified engineer will help you decide which type of mechanical seal is best for your application.

Mechanical seals are critical components in centrifugal pump systems. These devices preserve the integrity of the pump systems by preventing fluid leaks and keeping contaminants out. Mechanical seal systems are used on various seal designs to detect leakage, control the seal environment and lubricate secondary seals.

Depending on the pump type and the process variables, there are various mechanical seal types to choose from. Each seal variant has its unique design and characteristics which make it suitable for a specific application. MES has years of experience with industrial mechanical seals and support systems, making us an authority in this area.

Mechanical seal types vary in design, arrangement, and how they disperse the hydraulic forces acting at their faces. The most common seal types include the following:

Balanced mechanical seal arrangements refer to a system where the forces acting at the seal faces are balanced. As a result of the lower face loading, there is more even lubrication of the seal faces and longer seal life. Learn about our mechanical seal lubrication systems today.

Balanced mechanical seals are particularly suited to higher operating pressures, typically above 200 PSIG. They are also a good choice when handling liquids with low lubricity and higher volatility.

Unbalanced mechanical seal types are commonly employed as a more economical option to the more complex balance seal. Unbalanced seals may also exhibit less product leakage due to tighter control of the face film, but as a result can exhibit much lower mean time between failure. Unbalanced seals are not recommended for high pressure or most hydrocarbon applications.

Pusher seals utilize one or multiple springs to maintain seal closing forces. The springs can be in the rotating or stationary element of the mechanical seal. Pusher type seals can provide sealing at very high pressures but have a drawback due to the elastomer under the primary seal face that can be subjected to wear as the face moves along the shaft/sleeve during operation.

Non-pusher seals utilize a metal or elastomeric bellows to maintain seal closing forces. These seals are ideally suited to dirty and high temperature applications. Bellows seals are limited to medium/lower pressure applications.

Conventional seals are typically lower cost and often installed on general service equipment. These seals require higher operator skill to service as they installed as individual components.

Cartridge type mechanical seals incorporate all of the seal elements into a single assembly. This dramatically reduces the potential for assembly error and the time require for seal replacements. Learn more about the difference between cartridge and non-cartridge mechanical seals today.

When deciding on the type of seal system for a centrifugal pump, operators must choose according to their unique application. Failure to select the proper seal type can lead to loss of pump integrity, breakdowns and costly repairs. To avoid these undesirable results, all operators must consider the following factors before deciding.

The amount of pressure exerted at a mechanical seal’s faces has a significant effect on its performance. If a pump is to be operated at low pressures, an unbalanced mechanical seal will be suitable. However, in conditions where higher pressures are anticipated, balanced seals will prove a more reliable solution.

Balanced mechanical seals perform better than their unbalanced counterparts in conditions where the operating temperatures are higher than normal. Heat sensitive components are better preserved in balanced mechanical seals compared to other seal types.

As it goes for all types of machinery, operator safety is the top priority. The use of double mechanical seals in centrifugal pumps provides additional protection as they have increased sealing capacity and are generally more reliable.

There is an upside to change from packing to mechanical seals, however not all conditions favor seals, so a good general knowledge about sealing systems is important in the decision process.

The product being pumped enters a centrifugal pump through the suction nozzle at the center of a rotating impeller. As the impeller rotates, its vanes fill with fluid, then force it out to the pump casing (volute) where it exits the pump at the cutwater through the discharge nozzle.

The discharge pressure will force fluid back behind the impeller, where it attempts to exit by way of the rotating pump shaft. Some pump designs by manufacturers attempt to minimize this leakage, but it can not be stopped entirely. Some form of a sealing method must be applied to stop or minimize the leakage.

The greatest benefit of using mechanical seals is the drastic reduction in leakage. That reduction in leakage also has an effect on other things as well. Things like a safer work environment without a wet floor or possible contact with hazardous fluids. Fewer beating failures caused by leaking fluid and no damage from packing to the rotating shaft. The maintenance department also sees savings in time and budget. No more adjusting or replacing packing or sleeve. There also is a large reduction in power consumption versus packing. There is up to 40% reduction in friction loss with seals.

At Priest Electric we have the expertise and technical advice to help you in deciding the best sealing medium and represent some of the best manufacturers in the world.

In order to understand centrifugal pump leakage, it’s important to first understand the basic operation of a centrifugal pump. As the flow enters through the impeller eye of the pump and up the impeller vanes, the fluid is at a lower pressure and low velocity. When the flow passes through the volute, the pressure increases and the velocity increases. The flow then exits through the discharge, at which point the pressure is high but the velocity slows. The flow that goes into the pump has to go out of the pump. The pump imparts head (or pressure), which means it increases the energy of the pump fluid.

Certain component failures of a centrifugal pump, such as coupling, hydraulic, static joints, and bearings, will cause the whole system to fail, but approximately sixty-nine percent of all pump failures result from the sealing device malfunctioning.

A mechanical seal is a device that is used to control leakage between a rotating shaft and a liquid- or gas-filled vessel. Its main responsibility is to control leakage. All seals leak—they have to in order to maintain a fluid film over the entire mechanical seal face. The leakage that comes out the atmospheric side is fairly low; the leakage in a Hydrocarbon, for example, is measured by a VOC meter in parts/million.

Before mechanical seals were developed, engineers typically sealed a pump with mechanical packing. Mechanical packing, a fibrous material usually impregnated with a lubricant such as graphite, was cut into sections and stuffed down what was called a “stuffing box.” A packing gland was then added to the backside in order to pack everything down. Since the packing is in direct contact with the shaft, it requires lubrication, but will still rob horsepower.

Usually a “lantern ring” allows flush water to be applied to the packing. That water, necessary to lubricate and cool the shaft, will leak either into the process or into the atmosphere. Depending on your application, you may need to:

As with every pump, you’ll want to test your pump to discover the annual costs it requires to run. A packing pump may be affordable to install and maintain, but if you calculate how many gallons of water it consumes per minute or per year, you may be surprised by the cost. A mechanical seal pump could potentially save you a lot of annual costs.

If the centrifugal pump exhibits an uncontrolled leak, you must thoroughly check all potential causes to determine if you need repairs or a new installation.

Neglecting the Best Efficiency Point: Are you operating the pump at the Best Efficiency Point (BEP) on a performance curve? Each pump is designed with a specific Efficiency Point. When you operate the pump outside that region, you create problems with the flow that cause the system to fail.

Insufficient Net Positive Suction Head (NPSH): If you don’t have enough suction head to your pump, the rotating assembly can become unstable, cause cavitation, and result in a seal failure.

Operating Dead-Headed: If you set the control valve too low to throttle the pump, you can choke the flow. Choked flow causes recirculation within the pump, which generates heat and promotes a seal failure.

Dry Running & Improper Venting of Seal: A vertical pump is the most susceptible since the mechanical seal is positioned on top. If you have improper venting, air can get trapped around the seal and won’t be able to evacuate the stuffing box. The mechanical seal will soon fail if the pump continues to run in this condition.

Low Vapor Margin: These are flashing fluids; hot hydrocarbons will flash once exposed to atmospheric conditions. As the fluid film passes across the mechanical seal, it can flash at the atmospheric side and cause a failure. This failure often happens with boiler feed systems—hot water at 250-280ºF flash with the pressure drop across the seal faces.

Shaft misalignment, coupling imbalance, and impeller imbalance can all contribute to mechanical seal failures. In addition, after the pump is installed, if you have misaligned pipes bolted to it, you will impart a lot of strain on the pump. You also need to avoid a bad base: Is the base secure? Is it grouted properly? Do you have a soft foot? Is it bolted correctly? And last, check the bearings. If the tolerance of the bearings wears thin, the shafts will move and cause vibrations in the pump.

Do you have a good tribological (the study of friction) pair? Have you chosen the correct facing combinations? What about the seal face material quality? Are your materials appropriate for your specific application? Have you selected the proper secondary seals, such as gaskets and o-rings, that are prepared for chemical and heat attacks? Your springs should not be clogged or your bellows corroded. Last, keep an eye out for face distortions from pressure or heat, since a mechanical seal under great pressure will actually bow, and the skewed profile can cause a leak.

You need a proper seal flush arrangement, along with sufficient cooling. Dual systems have barrier fluids; the auxiliary seal pot needs to be in the right location, with the correct instrumentation and piping. You need to take the Length of Straight Pipe at Suction into account—some older pump systems that often came as a packaged skid include a 90º elbow at suction right before the flow enters the impeller eye. The elbow causes a turbulent flow that creates instabilities in the rotating assembly. All the suction/discharge and bypass piping needs to be engineered correctly as well, especially if some pipes have been repaired at some point over the years.

Other miscellaneous factors account for only about 8 percent of all failures. For example, auxiliary systems are sometimes required to provide an acceptable operating environment for a mechanical seal. For reference to dual systems, you need an auxiliary fluid to act as a barrier that prevents contamination or process fluid from spilling into the environment. However, for most users, addressing one of the first four categories will hold the solution they need.

Mechanical seals are a major factor in rotating equipment reliability. They’re responsible for leaks and failures of the system, but they also indicate problems that would eventually cause serious damage down the road. Seal reliability is greatly affected by the seal design and the operating environment.

Frank Rotello is mechanical seal reliability engineer for Cummins-Wagner. Cummins-Wagner Co., Inc. is a distributor for industrial and mechanical equipment covering the mid-Atlantic states with leading brands of compressors, pumps, and heat transfer equipment, and offer support services such as system design, assembly, and aftermarket service and repair. For more information, visit www.cummins-wagner.com.

A mechanical seal is a device used to contain fluid within a centrifugal pump or other vessel where a rotating shaft passes through a stationary housing. Mechanical seals for centrifugal pumps feature two sealing faces: a rotating or dynamic face which rotates with the shaft, and a static face, or seat, which remains stationary. The rotating face is made from a harder material than the static face, and as it spins, it wears a groove into the seat, which creates a liquid-tight seal.

Because the two faces of a mechanical seal are constantly rotating against one another, a significant amount of heat is generated. To keep the faces cool and lubricated, mechanical seals incorporate external flushing systems that pump coolant into the seal. This coolant is introduced at a higher pressure than the media being pumped to create positive pressure and keep the media from infiltrating the seal faces.

Delmar Company offers high quality, high performance mechanical seals for centrifugal pumps. We team with Flex-A-Seal, Vulcan, and other leading manufacturers to provide cartridge mechanical seals and single spring mechanical seals to give our customers effective sealing solutions for all pumping applications. Through these partnerships, we can provide mechanical seals that are interchangeable with cartridge seals or single spring seals from John Crane, U.S. Seal, Pac-Seal, Flygt, Flowserve, AES, Sepco, and other manufacturers.

More expensive than single spring seals but far easier to install, cartridge mechanical seals are self-contained devices with all parts and components in a single unit. Available in multiple configurations and with a variety of sealing face material combinations and o-ring options.

While installation is a much more involved process for single-spring mechanical seals, they are also significantly less expensive than cartridge seals. We offer single-spring seals for clockwise and counterclockwise rotating centrifugal pumps in a wide range of sizes and with numerous sealing face and o-ring material options.

Delmar Company offers full-service mechanical seal repair to extend the life of your cartridge seals at a fraction of the cost of replacement. Your damaged cartridge mechanical seals will be repaired to original OEM specifications.

Most customers already know the type, size, and/or configuration of mechanical seal their centrifugal pump requires. However, if you’re not sure what you need, Delmar Company can help you find the right option for your pump. To ensure that you receive the correct mechanical seal, we use a series of questions we call STAMPS. Please keep the following questions in mind when specifying the mechanical seal you need:

If you’re looking for a high quality, high-performance cartridge mechanical seal or single-spring mechanical seal for your centrifugal pump or mixer, look no further than Delmar Company. Request a quote or contact us today.

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

8613371530291

8613371530291