centrifugal pump mechanical seal manufacturer

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

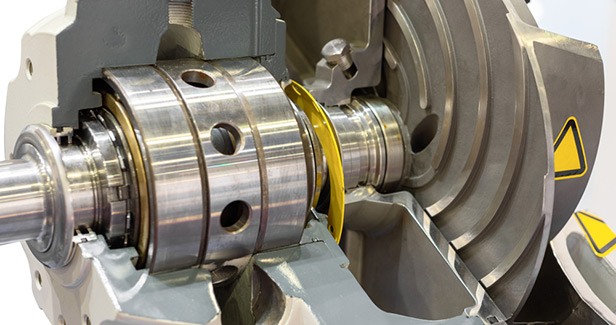

... pressurized gas barrier metal bellows seal utilizing APGS non-contacting seal face technology. Welded metal bellows eliminate dynamic O-ring hang-up in a compact cartridge that fits ANSI ...

• Drive mechanisms external to the product;• Seal faces positioned for maximum protection;• A dynamic elastomer moves on a non-metallic surface, eliminating fretting defects;• Hydraulically balanced;• Cartridge easy to ...

... install;• Metal bellows provide better faces alignment;• Does not have dynamic gaskets;• Self-cleaning;• Adapts to API standard pumps;• Available with stationary or rotating bellows.

Burgmann H74-D Mechanical Seal called as PC04 are specialized in mechanical seals products. This device gives double seal and it can be rotated in any ...

The M7N series is made of compact structure. It has a various application scope and high interchangeability. This series is widely used in petrochemical pumps. It is also embedded with drive collar that ...

The MTM10-11 is a conical spring mechanical seal developed by Microtem. It is mainly used for general services machinery at low and medium pressure. This unbalanced mechanical seal ...

The MTM 25_26, manufactured by MICROTEM, is a conical spring mechanical seal that can compensate positioning errors and withstand stresses created by vibrations. The contact surface can be made with silicon ...

... sealed tanks will have a mechanical seal of some sort. For many sanitary process vessels, the mixer must have some type of sealing barrier to provide either a dust tight vapor seal, a ...

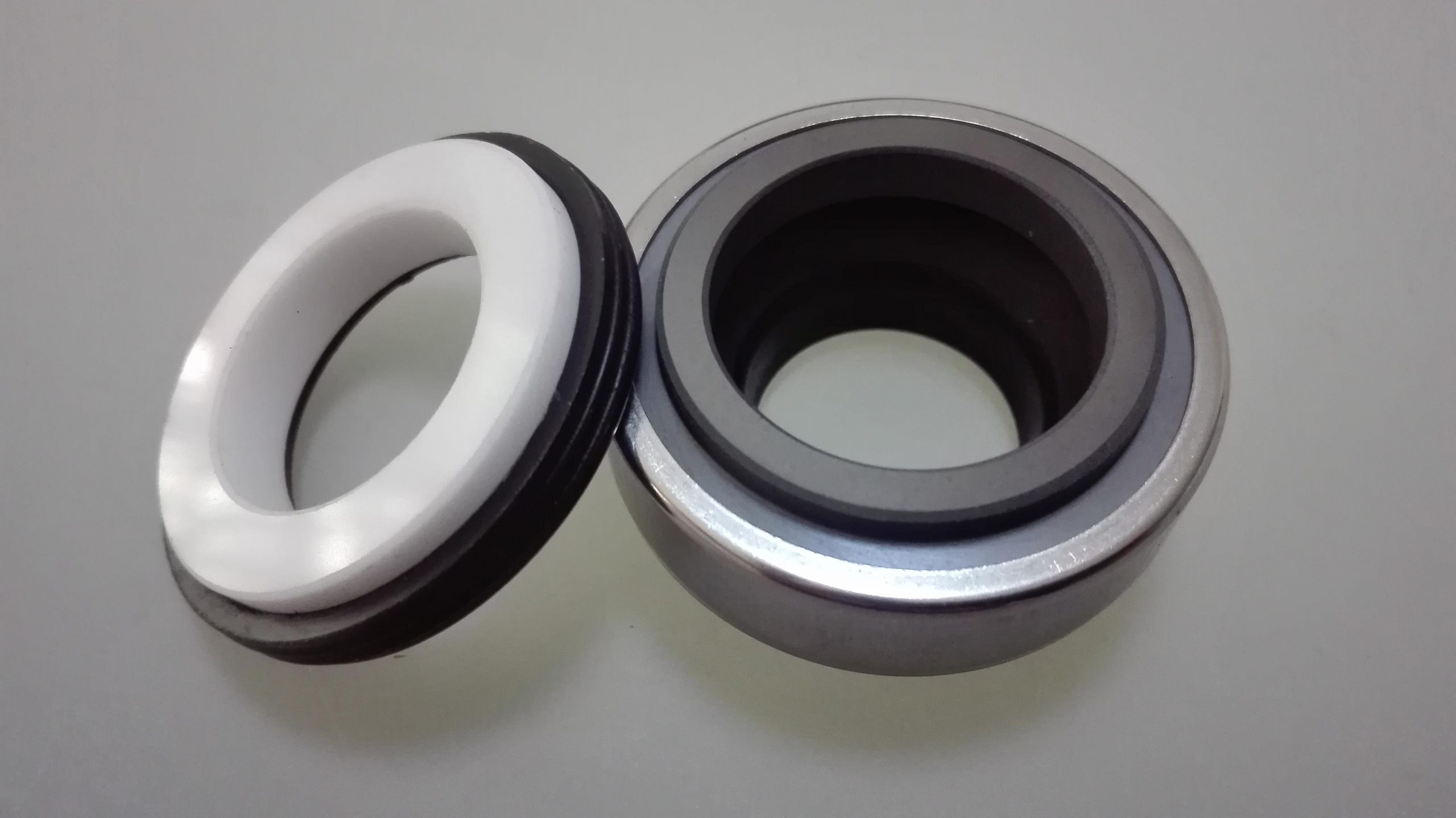

mechanical seal for automotive engine cooling water pump, referred to as water seal, mainly composed of two parts: rotating ring and static ring. Static ring is installed ...

The 3-D Seal is designed to be the foremost solution for high radial misalignment and high run out applications. By combining Garlock’s proven P/S®-II and expansion joint technologies into ...

... harnesses the rotational energy of the pump shaft to vaporize the process fluid at a controlled rate, creating a stable gas film that lubricates the seal faces. Typical problems, such as dry-running wear, ...

The AESSEAL® API Type A, B and C single-seal range offers the user an unprecedented range of API engineered sealing solutions to suit all application ...

Mechnical seal type 5030 / 5031 »with rubber bellowssingle-actingnon-anisotropicAreas of usestandard pumpwaster water pumpsupply engineeringgeneral industrial usemass production ...

Balanced Bi-directional Built-in flushing connections External pressurization Fully split single seal, 2 x 2 segments, preassembled Installation and wear control Semi-cartridge Stationary springs

... displacement vane pumps that are manufactured by Hof Hydraulic. They are equipped with a cartridge kit design which permits easy repair and interchangeability between pumps.

We manufacture face seals for hydraulic and pneumatic applications in the following designs:- rod seals and piston seals - single-acting - double-acting - rotatory seals ...

Single mechanical seal, balanced, independent of the direction of rotation with multi-spring configuration. The MTM180 Series represents the mechanical seal with the ...

Single mechanical seal, balanced, external, independent of the direction of rotation with multi-spring configuration. The MTM190 Series represents the mechanical seal ...

Single echanical seal, balanced, independent of the direction of rotation with multi-spring configuration. The springs are never in contact with the fluid. The MTM190 Series represents the mechanical ...

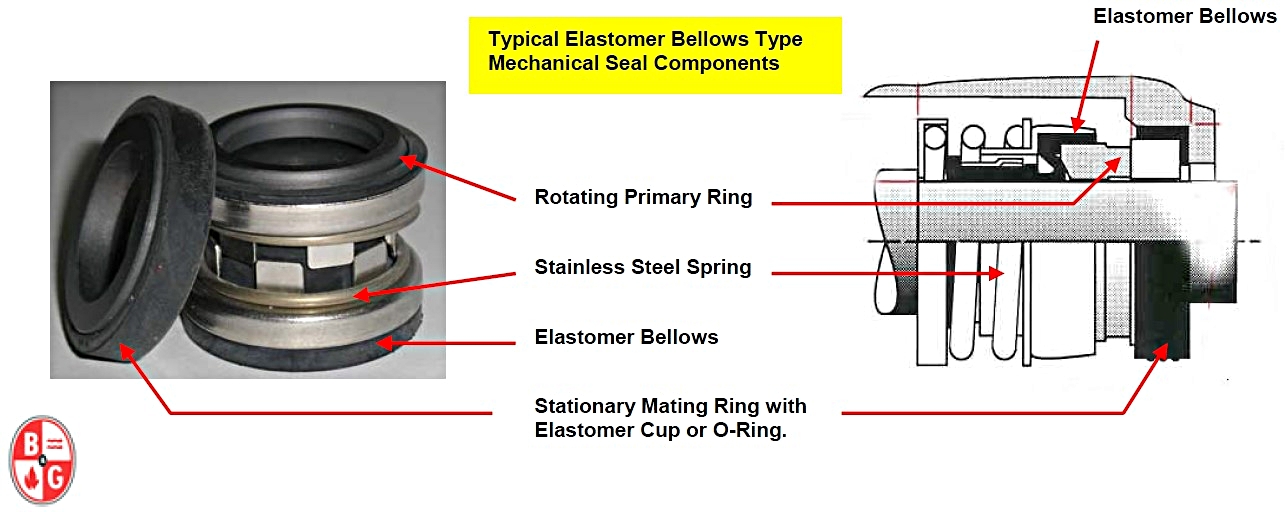

... demanding applications, the Type 2100 mechanical seal is a compact, unitized, single-spring elastomer bellows seal that offers maximum durability and performance.

MINKIX is a professional mechanical seal company that provides all kinds of inventory mechanical shaft seals for pumps, along with the same-day dispatch, and assures the aftermarket of higher quality, precision and performance.

We pride ourselves on being the in-stock supplier of mechanical seals that uses ERP to manage inventory. By doing so we are ensuring our clients are getting the right mechanical seals in the fastest manner possible.

With years of commitment to manufacturing quality seals and providing an excellent customer service, MINKIX is growing and gaining reputation and trust among wholesalers, distributors, and repair businesses.

Type 82/C – Grafoil Packing Cartridge mechanical seals are destined for petrochemical, chemical, pharmaceutical and food processing industry, for process pumps. Rotating bellows design acts to clear convolutions and prevent accumulation of debris. These bellow seals are constructed by welding a series of diaphragms together at the edges to form a bellows unit. Recommended for high temperature mediums e.g. hot oils, pitch, tar and other hydrocarbons, fuels, liquid gases and other mediums with low content of abrasives.

ISO 9001:2015 certified. Custom manufacturer of abrasion, acid, alcohol, alkali, oxidation, ozone, radiation, sunlight and water resistant rubber and plastic O-ring seals. Made from EPDM, butyl, fluoroelastomer, fluorosilicone, natural rubber, neoprene, nitrile, NBR, HNBR, SBR, silicone, high tear strength silicone, TPR, TPU, TPE, thermoplastics and polyurethane. Capabilities include injection molding, die cutting and prototyping. Assembly and PTFE coating additional services are also provided. Serves the aerospace, automotive, commercial, construction, dental, electrical, food handling, laboratory, marine, mining, municipal, oil and gas, recreational, retail, transportation and wastewater industries. Meets ASTM and SAE standards. Six Sigma certified. JIT delivery. Overseas sourcing options also offered.

Mechanical seals are critical components in centrifugal pump systems. These devices preserve the integrity of the pump systems by preventing fluid leaks and keeping contaminants out. Mechanical seal systems are used on various seal designs to detect leakage, control the seal environment and lubricate secondary seals.

Depending on the pump type and the process variables, there are various mechanical seal types to choose from. Each seal variant has its unique design and characteristics which make it suitable for a specific application. MES has years of experience with industrial mechanical seals and support systems, making us an authority in this area.

Mechanical seal types vary in design, arrangement, and how they disperse the hydraulic forces acting at their faces. The most common seal types include the following:

Balanced mechanical seal arrangements refer to a system where the forces acting at the seal faces are balanced. As a result of the lower face loading, there is more even lubrication of the seal faces and longer seal life. Learn about our mechanical seal lubrication systems today.

Balanced mechanical seals are particularly suited to higher operating pressures, typically above 200 PSIG. They are also a good choice when handling liquids with low lubricity and higher volatility.

Unbalanced mechanical seal types are commonly employed as a more economical option to the more complex balance seal. Unbalanced seals may also exhibit less product leakage due to tighter control of the face film, but as a result can exhibit much lower mean time between failure. Unbalanced seals are not recommended for high pressure or most hydrocarbon applications.

Pusher seals utilize one or multiple springs to maintain seal closing forces. The springs can be in the rotating or stationary element of the mechanical seal. Pusher type seals can provide sealing at very high pressures but have a drawback due to the elastomer under the primary seal face that can be subjected to wear as the face moves along the shaft/sleeve during operation.

Non-pusher seals utilize a metal or elastomeric bellows to maintain seal closing forces. These seals are ideally suited to dirty and high temperature applications. Bellows seals are limited to medium/lower pressure applications.

Conventional seals are typically lower cost and often installed on general service equipment. These seals require higher operator skill to service as they installed as individual components.

Cartridge type mechanical seals incorporate all of the seal elements into a single assembly. This dramatically reduces the potential for assembly error and the time require for seal replacements. Learn more about the difference between cartridge and non-cartridge mechanical seals today.

When deciding on the type of seal system for a centrifugal pump, operators must choose according to their unique application. Failure to select the proper seal type can lead to loss of pump integrity, breakdowns and costly repairs. To avoid these undesirable results, all operators must consider the following factors before deciding.

The amount of pressure exerted at a mechanical seal’s faces has a significant effect on its performance. If a pump is to be operated at low pressures, an unbalanced mechanical seal will be suitable. However, in conditions where higher pressures are anticipated, balanced seals will prove a more reliable solution.

Balanced mechanical seals perform better than their unbalanced counterparts in conditions where the operating temperatures are higher than normal. Heat sensitive components are better preserved in balanced mechanical seals compared to other seal types.

As it goes for all types of machinery, operator safety is the top priority. The use of double mechanical seals in centrifugal pumps provides additional protection as they have increased sealing capacity and are generally more reliable.

Amechanical seal is the most common type of sealing component used on pumps in modern industry. Replacing out packing over the last 50 or so years, they have served to drastically reduce industry emissions, energy usage and downtime globally.

A mechanical seal for pumps can be subdivided into variable options depending on the type/specific application/design components/location and mechanical seal characteristics;

The major advantage of a cartridge seal over a component seal is ease of installation. Incorrect installation is a major cause of seal failure, cartridge seals remove many of the problems associated with seal change-out in the field.

Slurry Seal – mechanical seal engineered to cope with a heavy slurry process – i.e. abrasive, corrosive and viscous. Can handle up to 60% slurrys by weight.

A Pusher Seal is where there is a spring element in the seal (used to maintain contact of the seal faces). Spring types include Belleville, multi-spring, etc. This type of seal requires a dynamic secondary seal.

A gas seal is a double seal where the barrier fluid is a gas – in pumps, this is usually a gas lift-off seal. In a gas lift-off seal the faces are not in contact while the machine is running. They are separated by a thin gas film (flow). If operated correctly they have very low wear.

The above seal types can be combined (though it is not always best to do so i.e. a component gas lift off seal would require very close collaboration between the machine and seal manufacturers to achieve a reliable installation).

There are many other options for mechanical seals, if you have any technical queries on other combinations not listed above, just contact one of our Mechanical Seal Specialists who will gladly discuss your application.

A mechanical seal flush is a piping set-up on a pump and seal assembly where a flow is induced in the seal chamber in order to improve MTBF of the mechanical seal. It is used to improve cooling, heating, remove solids and increase pressure (in combination with a neck or throat bush).

A mechanical seal quench is a piping set-up where a fluid is piped over the atmospheric side of a seal. It is generally used to prevent precipitation or crystallisation of a product or in some cases to aid cooling.

High Slurry process using Flowserve’s UNCD ® – Ultrananocrystalline diamond seal face technology. Flowserve UNCD ® coatings offer material properties and performance advancement over all other seal face materials.

Slurry seal design expertise applications which previously required double mechanical seals can now be reliably run by using single mechanical seals, saving costs of barrier fluid systems, the costs of the barrier fluid itself & the associated running costs. This reduces energy usage & carbon footprint.

If you have a technical query around the installation of mechanical seals for pumps or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running again.

1. DMS Seal Manufacturer works on producing the most reliable double mechanical seal centrifugal pump while achieving our value. Equipped with and , DMS Seal Manufacturer have won the trust of most customers. DMS Seal Manufacturer is known for its stable and reliable quality. Dms Seals Technology Co.,limited has grown to be a professional manufacturer and supplier for its natural rubber seal . In the ever changing market, DMS Seal Manufacturer always understands customers" needs and make change.

2. Our production capacity occupies steadily in the forefront of the flex seal manufacturer industry. All testing reports are available for our door seal suppliers . With advanced technology applied in rubber seal round , we take the lead in this industry. We adopt world-advanced technology when manufacturing mechanical seal pump price .

3. The assignment of Dms Seals Technology Co.,limited would be to give premium quality merchandise at competitive rates. Ask! DMS Seal Manufacturer provides quality service to every customer. Ask! Focusing on quality of service is what every DMS Seal Manufacturer employee has been doing. Ask! Our ultimate aim is to become a worldwide competitive carbon seal manufacturer exporter. Ask!

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

We offer a wide range of precision engineered custom KSB Pump Seals. We help to reduce the cost of plant ownership through enhanced sealing reliability and reduced maintenance, comprehensive technical services and lower transaction costs.

Mico seals specialize in manufacturing genuine Replacement Mechanical Seals for all major Pump manufacturer. we have well over 10 years of experience in the provision of Pump Mechanical seals for all applications.

We recognize and understand the vital role of centrifugal pump mechanical seal in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale centrifugal pump mechanical seal in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider centrifugal pump mechanical seal requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

Explore a wide variety of mechanical seal centrifugal pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These mechanical seal centrifugal pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these mechanical seal centrifugal pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right mechanical seal centrifugal pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of mechanical seal centrifugal pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Mechanical seals are designed to preserve the integrity of the pump system. They prevent fluid leaks and maintain a proper pressure seal within any centrifugal pump. The rotating shaft enters the back end of the pump casing by way of a stuffing box or seal chamber. To achieve better performance, safety, and durability, it is critical to select the right size and type of mechanical seal for your specific centrifugal pump, as well as for your pump application.

Mechanical seals feature two flat and smooth seal faces that work in unison. One will rotate with the shaft while the other remains stationary with the pump casing. Each seal face is connected to its respective halves with secondary seals, such as gaskets or o-rings. Mechanical seals can provide sealing flexibility to adjust for any slight misalignments while reducing potential wear on the various components.

Proper lubrication is key for healthy mechanical seals. The lubricating fluid will actually break down during operation, which creates a small release of vapor. It is natural and necessary for this vaporization to occur in a correctly functioning mechanical seal. Lubrication is an important step during mechanical seal installation and ongoing maintenance. Inspecting your mechanical seals is vital, and they should be adjusted, relubricated, or replaced as needed to keep your centrifugal pump leak-free.

There are several key steps for installing a new mechanical seal on your centrifugal pump. You will first need to shut off the pump motor and disconnect the power supply to ensure it cannot start up during maintenance. Then, all process fluid should be isolated and then drained from the pump housing.

Different centrifugal pump designs will have different ways to access the mechanical seal, some may be more complex than others. Consult the owner’s manual and follow the necessary procedures to safely access and remove the old mechanical seal. The impeller will also need to be removed during this stage. Ultimately, you will be able to remove both the rotary and stationary mechanical seal halves.

Make sure everything is clean and properly aligned during the installation of a new mechanical seal. Which mechanical seal is best for your pump may depend on a number of factors:

There are a wide variety of mechanical seals for centrifugal pumps from leading manufacturers like Flex-A-Seal, John Crane, Flowserve, and more. They are available in different sizes and configurations, as well as unique construction and coating materials to handle various process fluids.

Chemicals and liquids with acidic or corrosive qualities may call for a more robust mechanical seal made of a certain abrasion-resistant material. A standard seal solution may be adequate for less-aggressive fluid applications. It is very important to understand your application when it comes to selecting the best mechanical seal.

Once the mechanical seal is installed and everything is put back in place with proper alignment, you can refill and restart the pump. Monitor it carefully, it is working properly and there are no fluid leaks coming from the new mechanical seal. Test and adjust as much as necessary before running at full capacity. Continue to monitor and maintain your mechanical seals and all pump components for reliable performance and extended equipment lifespan.

For help with mechanical seal selection, installation and maintenance, contact the pump experts at DXP Pacific. We’re here to help with all of your pump services and we can match you with the best mechanical seal for your centrifugal pump and fluid application.

The scope of our mechanical pump seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety, John Crane has the right product for any application. Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of pump seals has you covered.

8613371530291

8613371530291