flowserve mechanical seal quotation

FLOWSERVE® CORP® (See DURCO®, IDP® and WORTHINGTON®) Search by the OEM Part Number using the SEARCH function at the top of the page or use search by specification.

OEM names, brands, model or part numbers are for identification purposes only. Our components are designed to provide performance and service life equal to or better than the OE part when properly installed and properly applied. Springer Parts® carry a warranty equal to the OE component. FLOWSERVE® CORP® (See DURCO®, IDP® and WORTHINGTON®) is a registered trademarks of its respective company. Springer Pumps, LLC is not a representative of, nor affiliated with FLOWSERVE® CORP® (See DURCO®, IDP® and WORTHINGTON®).

The use of the word “seal” is a misnomer; as a mechanical seal is a restrictive flow path,that is either an angular or radial gap.The flow through this gap is generally so low it goes unnoticed if a liquid or inconsequential if a gas.

A mechanical seal works byretaining a liquid or gas inside a rotating piece of equipment. Mechanical seals can be designed to prevent contamination of the process by the environment and prevention of leakage of the process into environment.

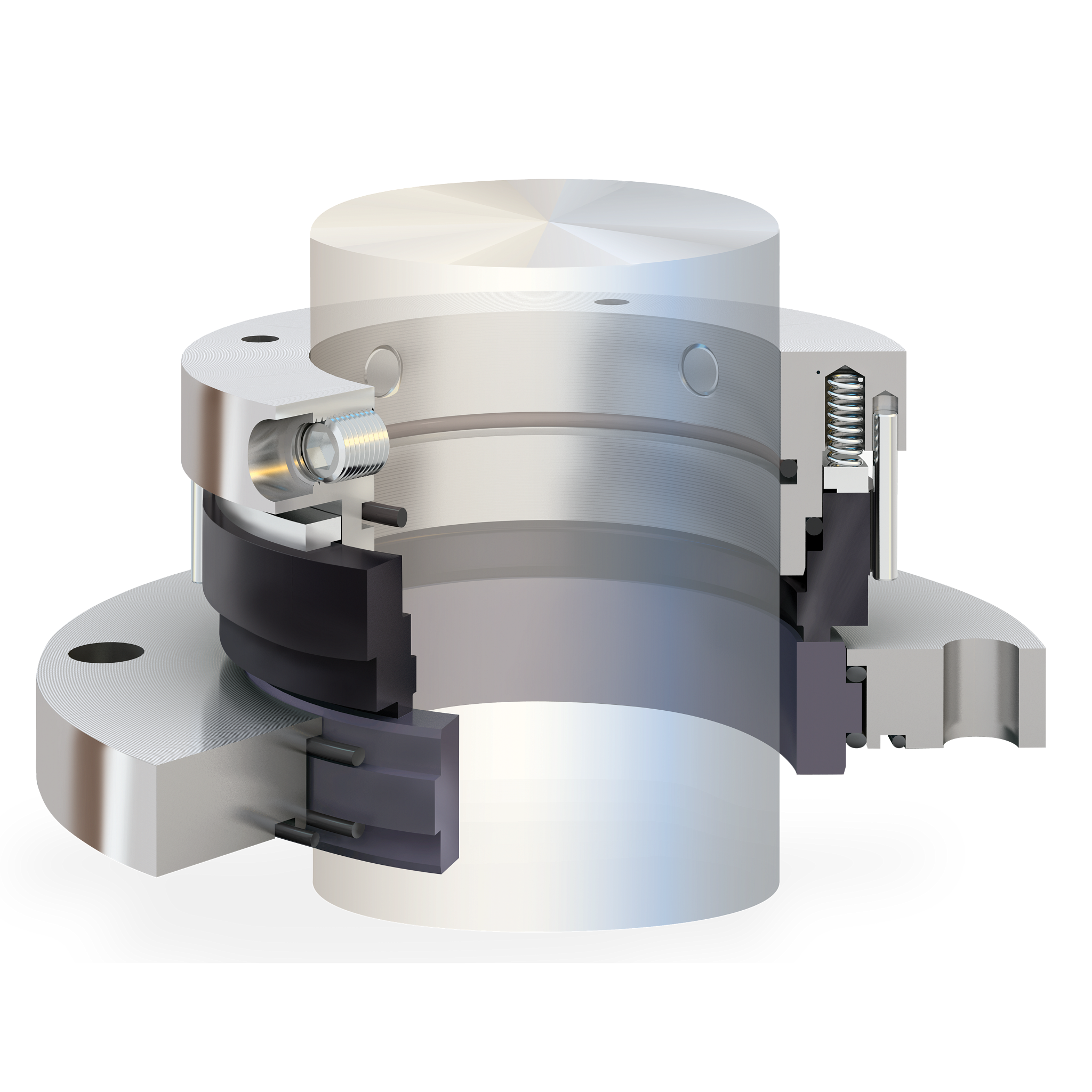

The basic components of a mechanical seal are a Rotating Part and a Stationary Part. The primary seal of a mechanical seal consists of a rotating face and a stationary face. The faces are kept lubricated by maintaining a thin film of fluid between each face. There is a very small gap between these 2 components which creates a restrictive flow path.

There are other components namely o-rings or gaskets which are used as secondary seals and hardware which is used to support the seal faces and to attach them to the rotating part (i.e shaft) and stationary part (i.e cover plate).

The primary seal of a mechanical seal is made up of 2 seal faces where these two parts meet is where the seal gap is located. The mating surface of the seal face is machined to a very tight tolerance.

Double Seal (Barrier) => consists of two primary seals in various arrangements. There is a barrier fluid between the two primary seals which is at a higher pressure than the process. There is always some leakage of the barrier fluid in process & out to atmosphere. As long as barrier pressure is maintained there is no leakage of process to atmosphere or contamination of process by environment.

Double Seal (Barrier) – Wet => is a double seal where the barrier is a liquid. It is generally the most robust seal. It has a good pressure, speed and temperature capabilities.

Gas Contacting Seal– the seal faces are in contact, the soft face wear acts as a lubricant. Low pressure, speed and temperature capabilities and possibilities of wear getting into the process.

Gas Non Contacting Seal – the seal faces are NOT in contact. They are kept apart by a flow of gas between the faces. Good temperature, speed and pressure capabilities. If operated correctly their is no wear but care must be taken in order to minimise shaft run out.

Cartridge seal =>is where the rotating and the stationary hardware are pre-assembled before mounting onto the pump/mixer. Cartridge seals are much easier to fit & maintain compared to the component seal.

A lip seal is a specific type of seal, it is a radial seal, where the part that seals against the rotating surface is a narrow cross section, soft material i.e the lip and it is made from an elastomer or non-elastomer material with a backup spring. Most commonly used to seal bearings in Mixers/Agitators. A lip seal rotates too quickly to be used on pumps.

Abarrier fluid is any gas or liquid which is used to pressurise a double mechanical seal. It must be compatible with the process, generally non-toxic and a good lubricant.

Please consult the pump manufacturer/distributor for guidance on these calculations for mixer seals, the barrier pressure is set at a certain value above the maximum vessel pressure.

Packing is a material that is stuffed between a rotating shaft and a stationary part gland to maintain pressure. Packing is a low cost alternative to mechanical seals.

We supply mechanical seals into the pharmaceutical, bio-technology, chemical processing, mineral and ore processing, semi-conductor and general industries.

Depending on your particular application, if you are looking mechanical seals to suit a pump application; Mechanical Seal for Pumps, or if you are trying to source mechanical seals for an agitator or tank mixer; Mechanical Seal for Agitator, or perhaps you have a hygienic application in mind, take a look at our range of Mechanical seal for Hygienic & Aseptic applications.

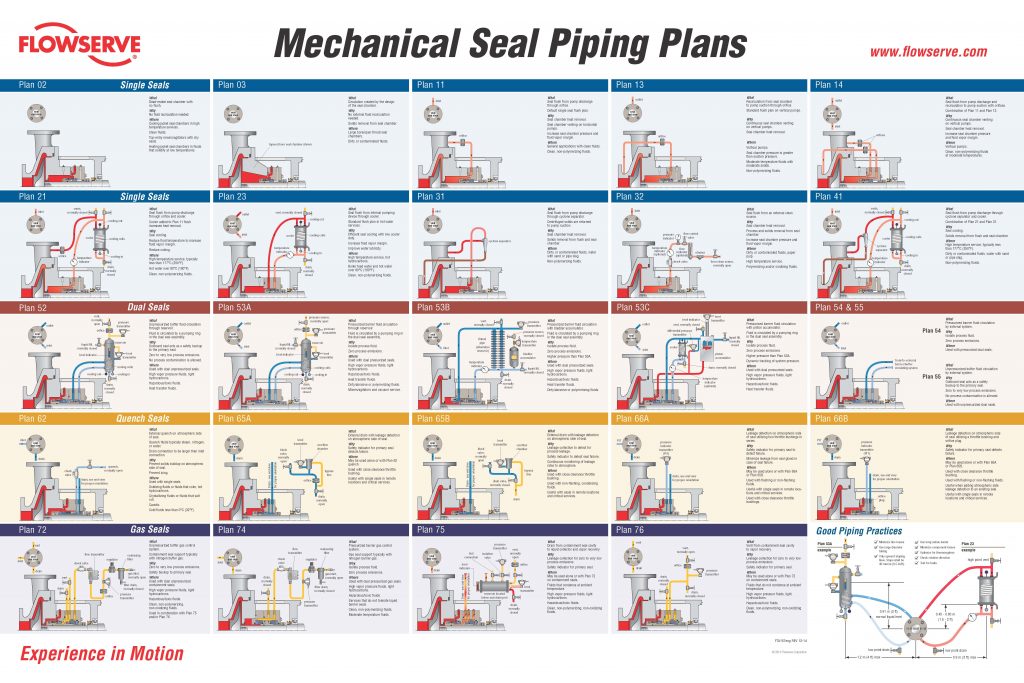

Our Mechanical Seal specialists can advise you on the appropriate selection of a seal support system which will deliver years of reliable service and operating cost savings in the longer term.

If you have any query around how to install mechanical seals or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running reliably again.

Siewert Equipment is the exclusive provider of Flowserve mechanical seals for Upstate, NY. Flowserve seals are the industry’s top choice for the most challenging environments. We offer a complete line of seals, including cartridge seals, dry-running seals, metal bellows, elastomeric bellows, mixer seals, split seals, and bearing protection devices.

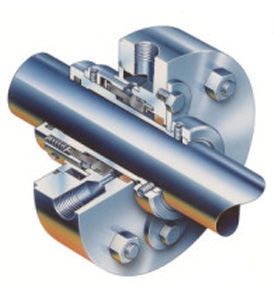

Flowserve"s PSSIII split mechanical seal is a 3rd generation masterpiece, requiring only one person to install. It"s reliable, repairable and quite remarkable, and it is best used on Split-Case pumps as well as Vertical Turbines.

Flexaseal offers replacement seals for a full array of compressors, mixers, pumps, and other rotating equipment. Direct replacements are available in standard inch and metric sizes and materials for major brands, including John Crane®, EagleBurgmann®, Pac Seal™, U.S. Seal Mfg™, and Flygt®. Replacements for custom designs are available on request.

Micro Sealsis one of the leading specialists in the design and manufacture of Pump Mechanical seals, Seal support systems ,Sealing Components,and Rotary Unions/Rotary Joints for Pumps, Agitator, Reactors, Blowers, mixers, steam turbines and other rotary-motion equipment. For over 15 years we’ve been committed to designing and manufacturing sealing products and accessories of the highest quality. We leads the way in high-efficiency solutions using the latest technologies for maximum sealing performance.

With over two centuries of experience, Flowserve products are designed with utmost safety and reliability in mind to help you reduce unplanned downtime while keeping workers, the public, and the environment safe. Flowserve supports this mission with over 180 Quick Response Centers to minimize downtime through fast, dependable response. The Flowserve seal product portfolio includes standard and engineered sealing solutions, seal support systems, and accessories for the Oil and Gas, Chemical, Power, Water and General Industrial Marketplace. Geiger is proud to represent Flowserve’s Mechanical Seal portfolio throughout Maryland, D.C., northern Virginia and Delaware.

Geiger’s application expertise in both Pumps and Sealing Solutions enables us to develop optimized approaches to solving your containment issues on even the most challenging services. Combining Geiger’s robust inventory and technical expertise with Flowserve’s vast resources and local Quick Response Centers, enables us to help you and your plant maximize resource efficiency and minimize downtime.

8613371530291

8613371530291