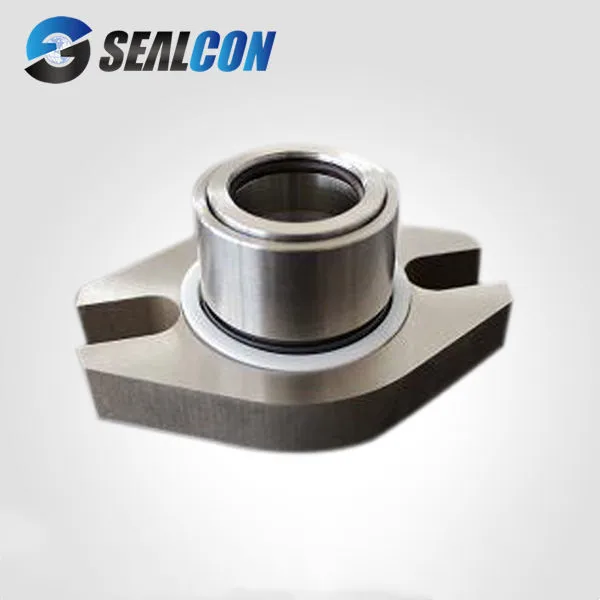

single cartridge mechanical seal for sale

Flexaseal offers a wide variety of single cartridge mechanical seals, each designed as a reliable solution for the toughest applications. Our single cartridge seals are easy to install and minimize the number of moving parts that can lead to equipment failure. Specially designed single cartridge seals are also available for highly corrosive or high-temperature environments. Cost-effective upgrades are available when circulation, vent, & drain glands are required.

Cartridge seals are a modern alternative designed to eliminate common causes of component seal failure. Check pump unit for defects before installing a cartridge seal to avoid damage to seal parts.

Single cartridge or double cartridge seals are self-contained units comprised of a shaft sleeve, seal, and gland plate. Cartridge seals are fitted onto the pump shaft as a single unit with no further fitting or assembly required.

Flexaseal offers a wide variety of single cartridge mechanical seals, each designed as a reliable solution for the toughest applications. Our single cartridge seals are easy to install and minimize the number of moving parts that can lead to equipment failure. Specially designed single cartridge seals are also available for highly corrosive or high-temperature environments. Cost-effective upgrades are available when circulation, vent, & drain glands are required.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

The Style 57 design serves to keep the sealing faces in contact and positively transmits the drive evenly 360° around the full circumference of the rotary face. This is accomplished by the special spring design, which provides an interference fit. The compression spring is wound either right or left hand depending on shaft rotation.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Stationary design accommodates higher shaft-to-stuffing box misalignment. The stationary bellows design only flexes once during installation unlike a rotating design which flexes on every revolution. This reduces face movement and increases seal life.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

These two single cartridge seals are engineered for the most demanding corrosive applications. By minimizing the number of troublesome O-rings and eliminating any media exposure to the sleeves and glands, we have produced two very cost effective solutions to industries’ toughest applications.

In highly corrosive conditions that require expensive upgrades to higher alloy metals like duplex stainless steel, Alloy 20, Hastelloy® C276, the PH seals are an ideal economical solution. Only the wetted parts need to be constructed of these alloys while the larger metal parts such as the gland and sleeve can be 316 stainless steel since they are located out of the product

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

API compliant with piloted gland to positively center seal assembly and metal-to-metal confined gland gasket which prevents blow out or extrusion of the gland packing

Multi-point injection feature available which ensures maximum uniformity of cooling around the entire circumference of the sealing faces, thus eliminating face distortion due to uneven cooling. Ideal for boiler feed and light flashing hydrocarbon services.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Conventional pump stuffing boxes were originally designed to accommodate packing materials. Over the years mechanical seals edged out packing as a preferred sealing method, however stuffing boxes essentially remained the same. This situation posed complications for the effective operation of mechanical seals including installation issues, potential damage from abrasive product, and poor dispersion of seal-generated heat.

The ANSI Standard ASME B73.1 Specifications for Horizontal End Suction Centrifugal Pumps for Chemical Process includes specifications to improve the reliability and safety of the B73.1 pump design. One major specification focuses on cylindrical (big bore) and self-venting (tapered bore) seal chambers. Both of these seal chamber designs address the issues that plagued conventional pump chambers by providing additional radial clearance for mechanical seal operation and for increased liquid circulation around the seal, enabling the seal to run cooler and longer.

Only two (2) static elastomers – eliminate seal failures caused by dynamic O-ring “hang up” and offers cost savings when upgrading to Perfluorelastomers

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

They are balanced and can be used in either direction of rotation. The energizing springs hold the seal faces together from outside the stuffing box, keeping them from clogging and losing compression.By making all of our seal faces "hard faces" your seals will last. In the short run our ASP SCS will help reduce your mechanical seal cost. In the long run your maintenance and clean up expenses are reduced. Our seals protect your bearings, and your budget.

Chesterton"s cartridge mechanical seals are the product of choice when reliability is a requirement.These products are proven, rugged performers in a wide range of sealing applications across industries. Cartridge seals are ideal for plant-wide standardization and save time witheasy installation. Chesterton"s cartridge seal offerings include exclusive, patented features such as self-centering lock rings and adjustable gland tabs.

A single mechanical seal consists of stationary and rotating seal faces that are made from one hard and one softer material. A single mechanical seal offers considerable cost and energy savings when used instead of gland packing.

All our single mechanical seals incorporate hydraulically balanced seal-face technology for reduced power consumption, helping our customers reduce their energy usage whilst increasing reliability.

A&S Seals Co., Ltd is a global supplier of Chesterton Mechanical Seals 150 Single Cartridge Mechanical Seal, Chesterton 150 Single Cartridge Mechanical Seal , Cartridge Seals Series, Chesterton Mechanical Seals and many more. focusing on the various brands of seals supply.

John Crane offers a wide range of standard cartridge seals that are versatile and easy to install, suit a wide range of duties and are commonly used in applications in the chemical, pulp & paper, power, food & beverage, mining, water/wastewater and general industries.

Designed to fit standard ANSI, DIN and ISO seal chambers they can also be used in a variety of rotary equipment. Our standard cartridge range provides you with reduced installation times, lower maintenance costs and optimal equipment performance.

Mechanical seals are available in several categories, including Single cartridge. Each category of mechanical seal is designed to address specific challenges and is suitable for particular applications.

Seals with shaft size 0, 0.5, 1, 1.125, 1.5, 1.625, 1.75, 2.375, 4, 11, 15, 19, 22, 23, 28 mm, 32 mm, 38 mm, 42, 50 mm, 60 mm, 65 mm, 72, 73, 76, 185, 225, 275

Mechanical seals are available in a variety of sizes, including 0 or 0.5 or 1 or 1.125 or 1.5 or 1.625 or 1.75 or 2.375 or 4 or 11 or 15 or 19 or 22 or 23 or 28 mm or 32 mm or 38 mm or 42 or 50 mm or 60 mm or 65 mm or 72 or 73 or 76 or 185 or 225 or 275. Selecting the right size mechanical seal is important for optimal performance and reliability. A mechanical seal with the correct shaft size ensures an accurate and secure fit on the pump shaft, distributing pressure correctly and preventing leakage.

Double cartridge mechanical seals have axial double-face seals and radial double-face seals. The radial double cartridge shaft seal’s structure is more compact than the axial double cartridge seal. Double cartridge pump seal is widely used in the media which is poor Lubricated, toxic, flammable, explosive, volatile, containing abrasive and gas etc.

The pre-installation of the dual cartridge mechanical seal is simple and easy to operate. It simplifies the process of measurement and adjustment, and has the characteristics of simple installation and strong interchangeability. The damage to the sealing element caused by the mechanical seal installation is avoided and the maintenance cost is reduced. With high quality imported special ceramics, corrosion resistant graphite, sintered carbide and other sealing materials, the life of the mechanical seal is improved.

Balanced seal ring design, can withstand higher pressure fluctuations of the medium; (3) stationary ring automatic compensation mechanism. Can overcome the influence of the angular offset of the end face and compensate the non-perpendicularity of the end face and the shaft;

Cartridge mechanical seals are widely used in all sectors of enterprises. Such as water pump plant, printing and dyeing machinery plant, paper mill, power plant, chemical plant, pharmaceutical shipyard and sewage treatment plant, and are widely used in hospitals, agriculture, equipment cooling, leather making industry, heavy machinery and so on.

The principle of the double cartridge mechanical seal is basically the same as Single cartridge mechanical seal. Both of them are constituted by the seal face (friction pair) perpendicular to the rotation axis, worked as Fluid leakage device based on the function of the fluid pressure and the compensation mechanism and the auxiliary seal. Double cartridge shaft seal has two face seals, if the primary seal fails, the secondary seal can still be sealed to prevent leakage.

The use of dual mechanical seal allows the cleaning fluid to be held between groups of surfaces. This allows the sealing surface can only see a clean lubricating fluid, greatly extending the life of the seal.

General dual mechanical seals are required for sealing liquid system. Sealing fluid is introduced into the sealed chamber for blocking, lubrication and cooling, and is mostly used for circulating cooling. Sealing fluid can not only wash the friction pair to improve the working environment of the mechanical seal, but also as an important sealing surface failure is an important means of detection.

A single cartridge type mechanical seal consists of two very flat surfaces that are pressed together by a spring and slide against each other. The single mechanical seal is a mechanical seal composed of 1 set of seal face. the sealing structure is simple, easy to manufacture and install features. Generally, cartridge type mechanical seal is used for the medium with good lubricity and allows a slight leakage. Single cartridge seals are one of the most commonly used centrifugal pump seal types. Single cartridge pump seals do not work well when the media is the toxic, flammable, explosive and strict requirement of leakage.

Mechanical seals tend to leak a vapor from the high-pressure side to the low-pressure side. This fluid lubricates the seal faces and absorbs the heat generated from the associated friction, which crosses the seal faces as a liquid and vaporizes into the atmosphere. So, it’s common practice to use a single cartridge mechanical seal if the pumped product poses little to no risk to the environment.

When a single cartridge seals used in the oil-filled motor, it is not only necessary to prevent the machine outside the impurities, sand and water to enter, but also to prevent the leakage of oil within the machine, so sealing requirements is higher, sealing ring material requirements need to be good, its sealing face material is made of tungsten carbide or silicon carbide. If it is installed on the shaft of the water-filled motor shaft, it only requires sand control. The sealing ring can be made of alumina ceramic, silicon nitride or other harder materials, so the cost is relatively low.

The installation error rate of the Common non-cartridge mechanical sea is higher than the cartridge mechanical seal. Therefore, use cartridge shaft seal can greatly reduce the occurrence of mechanical seal failure.

Since the cartridge mechanical seal does not require any adjustment of the mechanical seal by the installer (such as spring, sealing surface, etc.), only the bolts need to be tightened, which greatly improves the reliability of the mechanical seal installation.

Mechanical Seals are an integral part of many pumping systems. The right seal can protect and extend the life of your process pumps, while saving you downtime.

Edelmann & Associates offers PPC Mechanical Seals – a complete range of seal designs including single and double cartridge seals, metal bellows seals, split single and double seals, as well as custom engineered seals. Each is available in a broad range of materials and sizes for some of the most demanding applications throughout the process industry. We can even rebuild your existing mechanical seals.

chesterton mechanical seal is a world famous brand for cartridge mechanical seal, those seals are widely used for pumps, agitator, mixer, and other rotating machines.

chesterton 155 mechanical seal is a standard single cartridge mechanical seal, it is been treated as the perfect seal for all of your general-purpose plant applications. This simple mechanical seal design results in a more robust and reliable seal for general applications, while the low profile seal faces allow for low heat generation—making it ideally suited for non-lubricating fluids.

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

8613371530291

8613371530291