end face mechanical seal brands

The exclusive face pattern contains special shallow grooves to provide both hydrostatic and hydrodynamic lift of the seal faces resulting in reduced energy consumption during ...

Single mechanical seal, balanced, independent of the direction of rotation with multi-spring configuration. The MTM180 Series represents the mechanical seal with the ...

... dual unpressurized arrangement, without outboard seals also incorporating the same non-pusher technology, the seal can be configured to suit both the operator and pipeline needs.

The AESSEAL® API Type A, B and C single-seal range offers the user an unprecedented range of API engineered sealing solutions to suit all application ...

Metal encased, rubber bellow seals to full DIN24960 (EN12756)L1K compatibility. The Stramek seal face is retained to avoiddamage during seal installation.

... 10T TS 10R Our Mechanical seal model TS10T TS10R can replace John Crane 10R 10T. 10T is integral rotary face ,10R is insert rotary face Operating Limits Pressure: 1.3MPa ...

Validated by certificates from leading institutes and existing customers – make GOETZE® the first choice for face seals. GOETZE® manufactures their face seals completely in-house, from the casting to the finish grinding. State-of-the-art test rigs and optimized quality processes ensure the high quality of GOETZE® products. The materials, elastomer compositions and designs are perfectly adapted to the applications. Starting with an outer diameter of 50 millimeters, the dimensions reach up to 1,425 millimeters, a world record. In fact, the world’s largest cast face seals in open-castors, large-scale bogies and other large-scale machines bear the GOETZE® name.

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

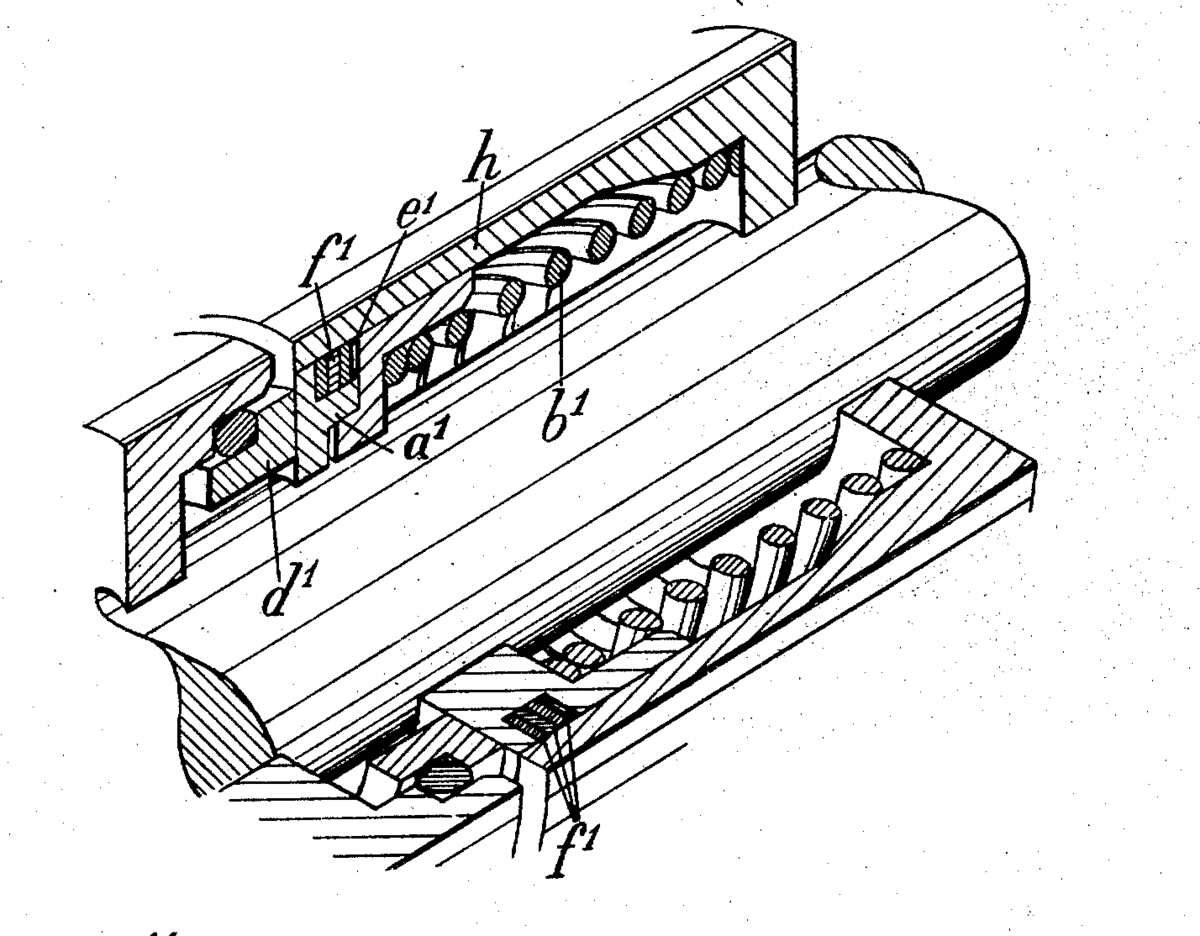

Elements d1 and a1 bear and slide on each other, creating a seal at their interface. One group of parts is connected to the rotating shaft and the other to the machine"s case. The spring keeps the elements tight against each other, maintaining the seal and allowing for wear.

An end-face mechanical seal, or a mechanical end-face seal, also referred to as a mechanical face seal but usually simply as a mechanical seal, is a type of seal used in rotating equipment, such as pumps, mixers, blowers, and compressors. When a pump operates, the liquid could leak out of the pump between the rotating shaft and the stationary pump casing. Since the shaft rotates, preventing this leakage can be difficult. Earlier pump models used mechanical packing (otherwise known as gland packing) to seal the shaft. Since World War II, mechanical seals have replaced packing in many applications.

An end-face mechanical seal uses both rigid and flexible elements that maintain contact at a sealing interface and slide on each other, allowing a rotating element to pass through a sealed case. The elements are both hydraulically and mechanically loaded with a spring or other device to maintain contact. For similar designs using flexible elements, see radial shaft seal (or "lip seal") and O-ring.

An end-face mechanical seal consists of rotating and stationary components which are tightly pressed together using both mechanical and hydraulic forces. Even though these components are tightly pressed together, a small amount of leakage occurs through a clearance that is related to the surface roughness.

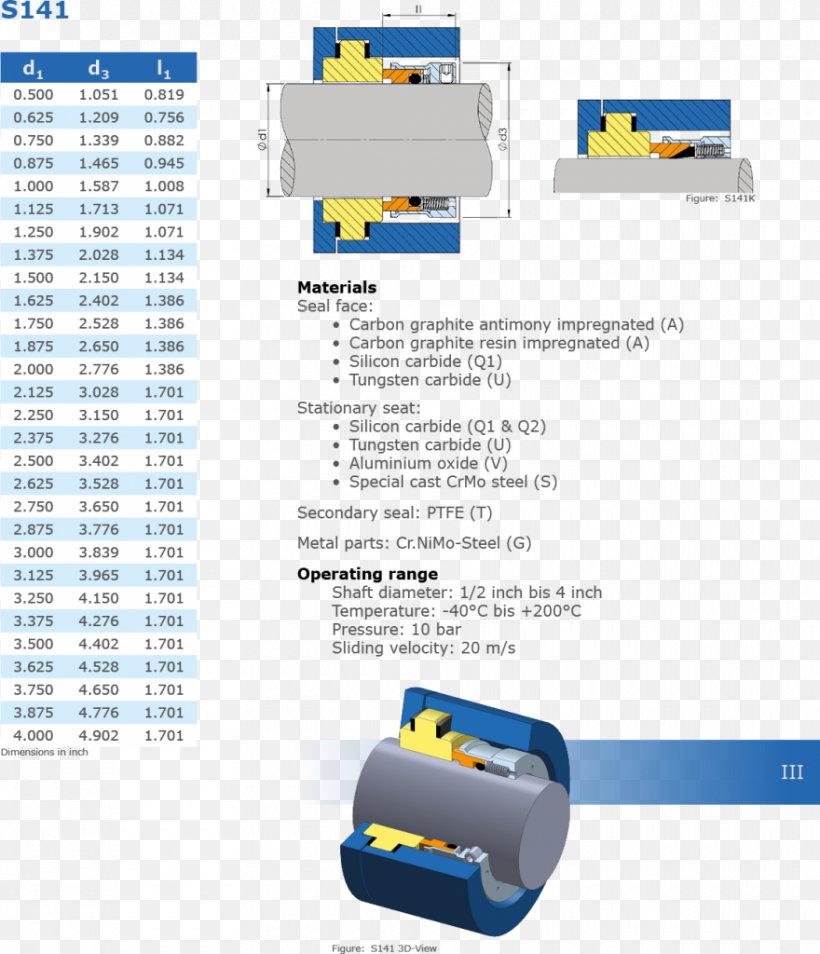

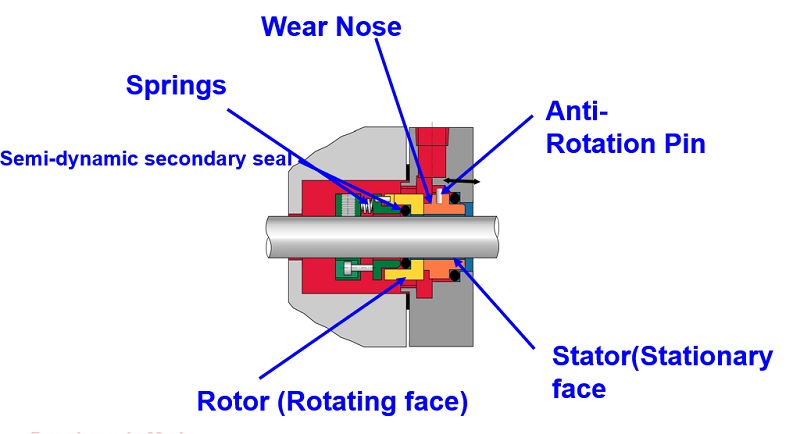

The seal ring and mating ring are sometimes referred to as the primary sealing surfaces. The primary sealing surfaces are the heart of the end-face mechanical seal. A common material combination for the primary sealing surfaces is a hard material, such as silicon carbide, ceramic or tungsten carbide and a softer material, such as carbon. Many other materials can be used depending on pressure, temperature and the chemical properties of the liquid being sealed. The seal ring and mating ring are in intimate contact, one ring rotates with the shaft and the other ring is stationary. Either ring may be rotating or stationary. Also, either ring may be made of hard or soft material. These two rings are machined using a process called lapping in order to obtain the necessary degree of surface finish and flatness. The seal ring is flexible in the axial direction; the mating ring is not flexible.

By definition, the seal ring is the axially flexible member of the end-face mechanical seal. The design of the seal ring must allow for minimizing distortion and maximizing heat transfer while considering the secondary sealing element, drive mechanism, spring and ease of assembly. Many seal rings contain the seal face diameters, although this is not a requirement of the primary ring. The seal ring always contains the balance diameter.

The shape of the seal ring may vary considerably according to the incorporation of various design features. In fact, the shape of the seal ring is often the most distinct identifying characteristic of a seal.

By definition, the mating ring is the non-flexible member of the mechanical seal. The design of the mating ring must allow for minimizing distortion and maximizing heat transfer while considering ease of assembly and the static secondary sealing element. The mating ring can contain the seal face diameters, although this is not a requirement of the mating ring. To minimize primary ring motion, the mating ring must be mounted solidly and should form a perpendicular plane for the primary ring to run against. Like seal rings, mating rings are available in many different shapes.

Secondary sealing elements are gaskets which provide sealing between the seal ring and shaft (or housing) and the mating ring and shaft (or housing). Typical secondary sealing elements include O-rings, wedges or rubber diaphragms. The secondary sealing elements (there may be a number of them) are not rotating relative to one another. The secondary sealing element for the mating ring is always static axially (although it may be rotating). Secondary sealing elements for the seal ring are described as being either pusher or non-pusher in the axial direction. The term pusher is applied to secondary seals that must be pushed back and forth by the movement of the shaft or primary ring whereas non-pusher secondary seals are static and associated with bellows seal rings.

In order to keep the primary sealing surfaces in intimate contact, an actuating force is required. This actuating force is provided by a spring. In conjunction with the spring, axial forces may also be provided by the pressure of the sealed fluid acting on the seal ring. Many different types of springs are used in mechanical seals: single spring, multiple springs, wave springs, and metal bellows.

The term "hardware" is used to describe various devices which hold the other components together in the desired relationship. For example, a retainer might be used to package the seal ring, secondary sealing element and springs into a single unit. Another example of hardware is the drive mechanism which is necessary to prevent axial and rotational slippage of the seal on the shaft.

There are a number of different ways in which “seals” may be classified. Sometimes a reference to a “seal” may be to a sealing system whereas other times the reference is to a device such as a gasket, an O-ring, compression packing, etc. In this article, the reference is to an end-face mechanical seal.

One such method of classification considers design features or the configuration in which these features may be used. Classification by Design accounts for the details and features incorporated into a single seal ring/mating ring pair. Classification by Configuration includes the orientation and combination of the seal ring/mating ring pair.

In general, design features are not completely independent; that is, emphasis of a particular feature may also influence other features. For example, selection of a particular secondary sealing element may influence the shape of the seal ring.

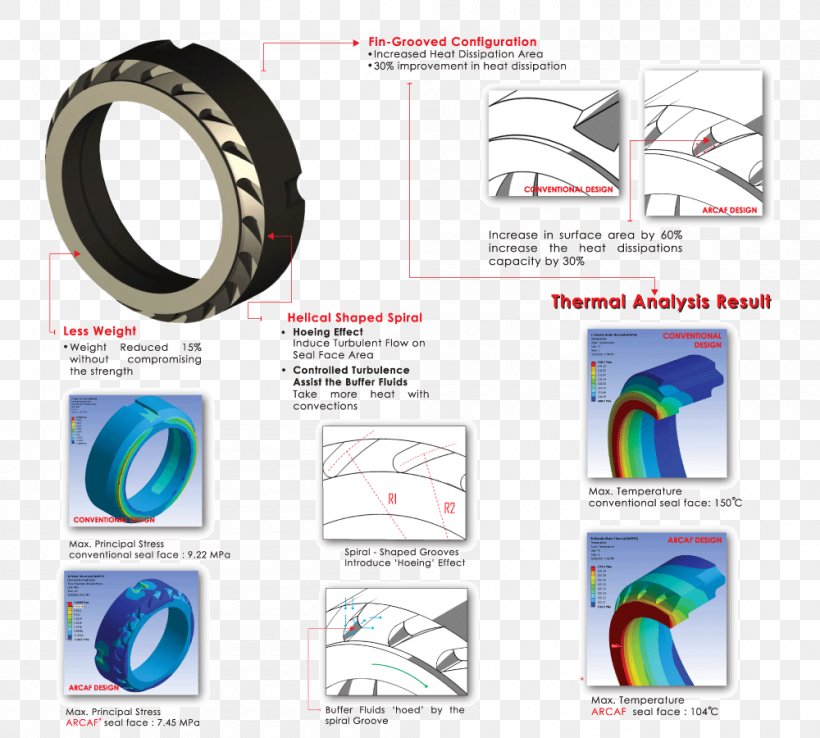

The most common seal face design is a plain, flat, smooth surface but there are many special treatments intended for specific applications. The most common objective for the face treatment is to reduce the magnitude of mechanical contact. In general, face treatments provide a means of modifying the pressure distribution between the seal faces through hydrostatic or hydrodynamic topography. Seal face topography refers to the three dimensional aspects of the seal face surface.

In addition to the spring force, the seal faces are pushed together through pressure acting hydrostatically on the geometry of the seal. The ratio of the geometric area tending to close the seal faces to the area tending to open the seal faces is called the balance ratio.

Pusher seals employ a dynamic secondary sealing element (typically an O-ring) which moves axially with the seal ring. Bellows seals employ a static secondary seal (such as an O-ring, high temperature graphite packing, or elastomeric bellows and axial movement is accommodated by contraction or expansion of the bellows.

In addition to retaining the other components, the seal hardware includes the drive mechanism which is necessary to prevent axial and rotational slippage of the seal on the shaft. The drive mechanism must withstand the torque produced by the seal faces while also allowing the seal ring to move axially. In addition to torque, the drive mechanism must withstand the axial thrust produced by hydrostatic pressure acting on the components. The various types of drive mechanisms include: dent drive, key drive, set screws, pins, slots, snap rings and many more. Typically, the retainer for the seal ring might include set screws, a dent or slot drive, recesses for the spring and a snap ring to complete the assembly. In contrast, mating ring hardware might be only a pin or slot to prevent rotation. Corrosion is a major consideration when selecting seal hardware.

Both the seal ring and mating must accommodate secondary sealing elements. In some designs, various retainers, sleeves and other components may also include secondary sealing elements. Whereas a simple O-ring might require only a groove for fitting, some secondary sealing elements (for example, packing) might require mechanical compression. Although O-rings are available in many elastomers, sometimes an elastomer might not be compatible with the fluid being sealed or might be considered too expensive. In such cases, a secondary sealing element might be manufactured from perfluoroelastomer and shaped in the form of a wedge, V or U.

Although all end-face mechanical seals must contain the five elements described above, those functional elements may be arranged or oriented in many different ways. Several dimensional and functional standards exist, such as API Standard 682 - Shaft Sealing Systems for Centrifugal and Rotary Pumps, which describes the configurations for used in Oil & Gas applications. Even though the scope of API 682 is somewhat limited, it may be extended to describe end-face mechanical seals in general.

Configuration refers to the number and orientation of the components in the end-face mechanical seal assembly. For example, springs may be rotating or stationary. Single or multiple pairs of sealing faces may be used. For multiple seals, the individual pairs of sealing faces may be similarly oriented or opposed. Containment devices such as bushings may or may not be used as part of the configuration.

The basic components of an end-face mechanical seal may be installed directly onto the shaft but a popular approach is to pre-assemble the components into some sort of package for ease of installation.

Either the seal ring or the mating ring may be the rotating element. Seals with rotating seal rings are said to be "rotating" seals; seals with stationary seal rings are said to be "stationary" seals. Because the springs are always associated with the seal rings, sometimes the distinction is made as "rotating springs" versus "stationary springs". For convenience, rotating seals are used in most equipment; however, stationary seals have some advantages over rotating seals. In small, mass-produced seals for modest services, the entire seal may be placed in a package which minimizes shaft and housing requirements for the equipment. Stationary seals are also used to advantage in large sizes or at high rotational speeds.

When classifying end-face mechanical seals by configuration, the first consideration is whether there is only one set of sealing faces or multiple sets. If multiple sets are used, are the sets configured to be unpressurized or pressurized.

A tandem seal consists of two sets primary sealing surfaces with the space in-between the two seals filled with a compatible low pressure fluid called the buffer fluid. This buffer fluid/space may be monitored to detect performance of the assembly. Unfortunately, the definition of “tandem seal” was often stated in a confusing manner. In particular, a tandem seal was usually described as two seals pointing in the same direction; that is, in a face-to-back orientation. This orientation is not necessary to the function of the configuration and the API chose to use the term Arrangement 2 instead of tandem in the API 682 standard.

A double seal consists of two sets primary sealing surfaces with the space in-between the two seals filled with a compatible pressurized fluid called the barrier fluid. This barrier fluid/space may be monitored to detect performance of the assembly. Unfortunately, the definition of “double seal” was often stated in a confusing manner. In particular, a double seal was usually described as two seals pointing in the opposite direction; that is, in a back-to-back orientation. This orientation is not necessary to the function of the configuration and the API chose to use the term Arrangement 3 instead of double in the API 682 standard.

An end-face mechanical seal generates heat from rubbing and viscous shear and must be cooled to assure good performance and reliable operation. Typically, cooling is provided by circulating fluid around the seal. This fluid, known as a flush, may be the same as the fluid being sealed or an entirely different fluid. The flush may be heated, filtered or otherwise treated to improve the operating environment around the seal. Collectively, the flush and treating systems are known as piping plans. Piping plans for mechanical seals are defined by American Petroleum Institute specification 682 and are given a number. Some piping plans are used for single seals and some only for multiple seals. Some piping plans are intended to provide a means of monitoring the seal. Some sealing systems include more than one piping plan. See the table below for a summary and description of piping plans.

The first commercially successful mechanical seal to be used on centrifugal pumps was probably made by the Cameron Division of the Ingersoll-Rand Company. The Cameron seal was installed in a number of centrifugal pipeline pumps in 1928.

Mechanical seals in the 1930s often used a face combination of hardened steel versus leaded bronze. Carbon-graphite was not widely used as a seal face material until after World War II. Soft packing was used as secondary sealing elements. The O-ring was developed in the 1930s but not used in mechanical seals until after World War II.

In the late 1930s, probably about 1938 or 1939, mechanical seals began to replace packing on automobile water pumps. The famous Jeep of WWII used a rubber bellows seal in the water pump. After WWII, all automobile water pumps used mechanical seals.

In the mid-1940s pump manufacturers such as Ingersoll-Rand, Worthington, Pacific, Byron Jackson, United, Union and others began to make their own mechanical seals. Eventually most of these companies got out of the seal business but the Byron Jackson seal became the Borg-Warner seal (now Flowserve) and the Worthington seal was sold to Chempro (now John Crane - Sealol).

Cartridge seals were used on a regular basis by 1950; this convenient packaging of seal, sleeve and gland was probably developed by C. E. Wiessner of Durametallic about 1942.

By 1954, mechanical seals were used with such regularity in the refining and process industries that the American Petroleum Institute included seal specifications in the first edition of its Standard 610, "Centrifugal Pumps for General Refinery Services".

By 1956, many of the conceptual designs and application guidelines that are in use today had been developed. Commercially available designs included both rotating and stationary flexible elements, balanced and unbalanced hydraulic loading, rubber and metal bellows, and a wide variety of spring designs and types. Secondary sealing elements included O-rings, wedges, U-cups and various packings. Carbon-graphite was widely used as a seal face material; the mating seal face was often cast iron, Ni-resist, 400 series stainless steel, Stellite or aluminum oxide although tungsten carbide was coming into use. Stainless steel was widely used for springs, retainers, sleeves and glands. Single and multiple seal arrangements were used as necessary to accomplish the required performance. In 1957, Sealol introduced the edge welded metal bellows seal. Previously, metal bellows seals had used a formed bellows which was much thicker and stiffer.

In 1959, John C. Copes of Baton Rouge, LA filed for a patent on a split seal and was awarded Patent #3025070 in 1962. In the Copes design, only the faces were split. Copes chose to provide custom split seals which he manufactured himself so very few of his split seals were produced.

The Clean Air Act of 1990 placed limits on fugitive emissions from pumps. Seal manufacturers responded with improved designs and better materials. In October, 1994, the American Petroleum Institute released API Standard 682, "A Shaft Sealing Systems for Centrifugal and Rotary Pumps”. This standard had a major effect on the sealing industry. In addition to providing guidelines for seal selection, API 682 requires qualification testing by the seal manufacturers.

Today, in addition to face patterns such as spiral grooves and waves, materials have been developed that have special surfaces to promote hydrodynamic lift. Lasers can be used to etch microscopic, performance enhancing textures on the surface of the seal face. Piezoelectric materials and electronic controls are being investigated for creating truly controllable seals. The application of specialized seal face patterns, surfaces, and controls is an emerging technology that is developing rapidly and holds great promise for the future.

API Standard 682, Fourth Edition, 2014, “Pumps – Shaft Sealing Systems for Centrifugal and Rotary Pumps,” American Petroleum Institute, Washington D.C.

Schoenherr, K. S., "Design Terminology for Mechanical End Face Seals", Society of Automotive Engineers Transactions, Vol. 74, Paper Number 650301, (1966).

Buck, G. S., Huebner, M. B, Thorp, J. M., and Fernandez, C. L. “Advances in Mechanical Sealing – An Introduction to API-682 Second Edition”, Texas A&M Turbomachinery Symposium, 2003.

Mechanical shaft seals are the best way to seal a pump. Face seals prevent leakage better than packing and if selected properly will last longer. Mechanical seals used in clean well lubricated applications can last 20 years. Seals can be constructed in single or double configurations, allowing only a vapor to escape.

Shaft seals are engineered forshaft-sealingapplications to serve Original Equipment Manufacturers or field replacement requirements, our seals will hold up to difficult applications. We can also asset in theconversion from braided pump packing to a mechanical seal.

American Seal and Packing delivers a full range of rotary mechanical seals configurations and component materials - to handle pump service requirements in a wide range of industries. . When you Specify a AS&P seals you have the advantage of proven reliability. When we need engineered seals for difficult applications we utilize the engineering departments of some of the top mechanical seal manufacturersin the world.

Mechanical seals are end-face seals that use a pair of faces perpendicular to the rotating shaft (sliding surfaces) to seal. The sealing faces, smoothly finished with high accuracy, enable long-term maintenance-free usage.

Mechanical seals manufactured by Eagle Industry Co., Ltd. are products achieving excellent performance and low running costs that feature highly accurately finished flat sealing faces, enabling long-term maintenance-free usage.

Mechanical seals withstand usage in various applications in different pumps for automobiles, households, civil engineering and construction, and in processing and chemical fields such as petrochemicals, nuclear energy, and space development, and have a wide range of use.

Mechanical seals TSUMO [ Water Pump Seal ] are used for shaft sealing of pumps, agitators, reactors and many. Primary purpose of the mechanical seal is to prevent leakage of liquid past the stuffing box. Mechanical seal are better than traditional gland packing as packing tends to leak.

Mechanical seal"s face combination depends mostly on liquid application, temperature, pressure.An end face mechanical seal, also referred to as a mechanical face seal but usually simply as a mechanical seal, is a type of seal utilised in rotating equipment, such as pumps and compressors.

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

The right seal support system is critical for promoting seal reliability. John Crane customizes support systems to meet a variety of seal specifications, contributing to safe, cost-effective, reliable operation and reducing harmful environmental effects. Our support systems comply with constantly changing design codes and standards, and meet the increasingly stringent demands on end users.

Our comprehensive suite of seal face technologies are designed to overcome rigorous sealing challenges, including limited seal face lubrication and severe-service duties that adversely affect reliability, operational costs and seal life. Designed by our engineering experts, John Crane’s face treatment options help your equipment power through low-lubricity and dry-running conditions by using advanced micromachined patterns and features to improve seal face lubrication to optimize the performance of rotating equipment in all process industries

Isomag’s advanced magnetic face technology delivers unparalleled performance. The lapped flat faces create a positive liquid tight seal preventing lubricant leakage and the ingress of contaminants in both static and dynamic conditions on horizontal and vertical equipment alike. By optimizing the magnetic energy loading, Isomag’s are capable of running at shaft speeds well above average (up to 15,000 feet per minute) providing the ability to effectively seal the bearing housings on a wide variety of applications

Often your very method of production will introduce contamination to your process, whether from imperfect ingredients, necessary reagents or process equipment, and to deliver an end product free from impurity and contamination, inhibiting, filtering action is required. Filtration is typically an imperfect process - some fluid remains on the feed side of the filter and fluid and particulates become embedded in the filter media.

Do you want to minimize leakage from your pumps in an effective manner? This is a challenge operators and maintenance managers face on a daily basis, which can prove costly. John Crane offers a wide selection of packing materials in compression packing, automatic packing, floating packing, and injectable packing. Learn more about our variety of packing equipped to handle the vast majority of sealing solutions and available for nearly all applications.

KLOZURE® Mechanical Seals are engineered to meet the demands of challenging sealing applications. Through the innovative use of materials, configurations, and custom designs for pumps, mixers, and agitators, KLOZURE® Mechanical Seals can handle abrasive, viscous, or adhesive media. KLOZURE®’s high-performance seals minimize equipment downtime, environmental leakage, and lost product.

To improve pump and mixer time between overhauls and reduce the total cost of ownership of specialized equipment, utilize the engineering and materials expertise of the KLOZURE® Mechanical Seal Family. Ideal for Food, Pharmaceutical, Pulp and Paper, Asphalt, and Chemical Production, the KLOZURE® Mechanical Seal portfolio is infinitely customizable.

KLOZURE® Mechanical Seals with P/S Technology utilize flexible GYLON elements for a non-clogging design perfect for abrasive, viscous, or adhesive media, as well as offering high run-out capable solutions.

An end face mechanical seal, also referred to as a mechanical face seal but usually simply as a mechanical seal, is a type of seal utilised in rotating equipment, such as pumps and compressors. When a pump operates, the liquid could leak out of the pump between the rotating shaft and the stationary pump casing. Since the shaft rotates, preventing this leakage can be difficult. Earlier pump models used mechanical packing to seal the shaft. Since WWII, mechanical seals have replaced packing in almost all applications.

An end face mechanical seal uses both rigid and flexible elements that maintain contact at a sealing interface and slide on each other, allowing a rotating element to pass through a sealed case. The elements are both hydraulically and mechanically loaded with a spring or other device to maintain contact. For similar designs using flexible elements, see radial shaft seals and o-rings.

A mechanical seal must contain four functional components: 1) Primary sealing surfaces, 2) Secondary sealing surfaces, 3) a means of actuation and 4) a means of drive.

1) The primary sealing surfaces are the heart of the device. A common combination consists of a hard material, such as silicon carbide or tungsten carbide, embedded in the pump casing and a softer material, such as carbon in the rotating seal assembly. Many other materials can be used depending on the liquid"s chemical properties, pressure, and temperature. These two rings are in intimate contact, one ring rotates with the shaft, the other ring is stationary. These two rings are machined using a machining process called lapping in order to obtain the necessary degree of flatness.

2) The secondary sealing surfaces (there may be a number of them) are those other points in the seal that require a fluid barrier but are not rotating relative to one another.

3) In order to keep the two primary sealing surfaces in intimate contact, a means of actuation must be provided. This is commonly provided by a spring. In conjunction with the spring, it may also be provided by the pressure of the sealed fluid.

4) The primary sealing surfaces must be the only parts of the seal that are permitted to rotate relative to one another, they must not rotate relative to the parts of the seal that hold them in place. To maintain this non-rotation a method of drive must be provided.

All Mechanical seals must contain the four elements described above but the way those functional elements are arranged may be quite varied. The standards of modern mechanical seals are widely defined by API Standard 682 - Shaft Sealing Systems for Centrifugal and Rotary Pumps.

Mechanical seals are generally classified into two main categories: "Pusher" or "Non-Pusher". These distinctions refer to whether or not the secondary seal to the shaft/sleeve is dynamic or stationary. Pusher seals will employ a dynamic secondary seal (typically an o-ring) which moves axially with the primary seal face. Non-pusher seals will employ a static secondary seal (either an o-ring, high temperature graphite packing, or elastomeric bellows). In this case, the face tracking is independent of the secondary seal which is always static against the shaft/sleeve.

Since the rotating seal will create heat, this heat will need to be carried away from the seal chamber or else the seal will overheat and fail. Typically, a small tube connected to either the suction or the discharge will help circulate the liquid. Other features such as filters or coolers will be added to this tubing arrangement depending on the properties of the fluid, and its pressure and temperature. Each arrangement has a number associated with it, as defined by American Petroleum Institute "API" specifications 610 and 682.

Since almost all seals utilize the process liquid or gas to lubricate the seal faces, they are designed to leak. Process liquids and gases containing hazardous vapors, dangerous chemicals or flammable petroleum must not be allowed to leak into the atmosphere or onto the ground. In these applications a second "containment" seal is placed after the primary seal along the pump shaft. The space in between these two seals is filled with a neutral liquid or gas called a "buffer" or "barrier" fluid.

In a tandem seal, the seal will leak into the buffer fluid contained in the unpressurized cavity. If the cavity registers a dramatic increase in pressure, operator will know that the primary seal has failed. If the cavity is drained of liquid, then the secondary seal failed. In both instances, maintenance will need to be performed. This arrangement is commonly used when sealing fluids that would create a hazard or change state when contacting open air. These are detailed in API Piping Plan 52

In a double seal, the barrier liquid in the cavity between the two seals is pressurized. Thus if the primary seal fails, the neutral liquid will leak into the pump stream instead of the dangerous pumped fluid escaping into the atmosphere. This application is usually used in gas, unstable, highly toxic, abrasive, corrosive, and viscous fluids. These are detailed in API Piping Plan standards #53a, 53b, 53c; or 54.

Tandem and double seal nomenclature historically characterized seals based on orientation, i.e, tandem seals mounted face to back, double seals mounted back to back or face to face. The distinction between pressurized and unpressurized support systems for tandem and double seals has lent itself to a more descriptive notation of dual pressurized and dual unpressurized mechanical seal. This distinction must be made as traditional "tandem seals" can also utilize a pressurized barrier fluid.

The Mechanical Seal was invented by George Cook and was originally called a "Cook Seal." He also founded the Cook Seal Company. Cook"s seal (which actually did not have a means of drive) was first used in refrigeration compressors.

The Cook Seal company was a sideline product for Cook and he sold the company to Muskegon Piston Ring Company where it was renamed as The Rotary Seal Division of Muskegon Piston Ring Co. Muskegon Piston Ring sold the Rotary Seal Division to EG&G Sealol who in turn was largely acquired by John Crane Industries of Morton Grove, IL.

John Crane was founded in 1917 as Crane Packing Company, the company established several facilities throughout the United States, Canada and England. John Crane had been in the Mechanical seal business for many years prior to this acquisition and in fact had long since exceeded Sealol in overall market size.

R.P. Gabriel, S.K. Niamathullah, Design and testing of seals to meeting API 682 requirements, in Proceedings of the 13th International Pump Users Symposium, (Turbo-Machinery Laboratory, Texas A&M University, College Station, March 1996)

J.L. Morton, J. Attard, J.G. Evans, Active lift seal technology impact on water injection services, in 22nd International Pump Users Symposium (Turbo-machinery Laboratory, Texas A & M University, College Station, March 2005)

J.P. Netzel, Chapter 2.2.3., Centrifugal Pump Mechanical Seals, in Pump Handbook, ed. by I.J. Karassik, J.P. Messina, P. Cooper, C.C. Heald, 3rd edn. (McGraw-Hill, New York, 2001), pp. 2.197–2.237

K. Schoenherr, Fundamentals of Mechanical End Face Seals, in Reprinted from Iron and Steel Engineer, Printed in Engineered Fluid Sealing (John Crane, Inc. 1976)

K. Schoenherr, R.L. Johnson, Seal Wear, in Wear Control Handbook, ed. by M. Peterson, W. Winer (American Society of Mechanical Engineers, New York, 1980)

J.R. Wasser, R. Sailer, G. Warner, Design and development of gas lubricated seals for pumps, in 11th Internation Pump Users Symposium. (Turbo-machinery Laboratory, Texas A&M University College Station, March 1994)

John Crane Mechanical Seals, part of the Smiths Group of the United Kingdom, is headquartered in Chicago, Illinois. John Crane is the largest and one of the oldest seal companies being incorporated as Crane Packing Company on March 9, 1917 in Chicago, Illinois.

Frank E. Payne, founder of Crane Packing Company, was a salesman for the Warren Steam Pump Company when he first heard about a local mechanic, John Crane, who made his own variation of metallic packing for pumps. Legend is that Crane discovered the improvement by wrapping his metal foil cigar wrapper around conventional packing. For a while, Payne sold metallic packing for John Crane on a commission basis but he left Warren Pump in 1916 to go into partnership with Crane. Although John Crane soon sold his shares and left the company, Payne kept the name Crane Packing Company for the business.

In the mid 1930’s Crane Packing Company licensed a mechanical seal design from Chicago Rotary Seal. Through several Crane patents, this design evolved into the full convolution rubber bellows seal. By 1938, Crane Packing Ltd in England was making their own mechanical seals for pumps in oil refineries.

In the late 1930’s, probably about 1937, mechanical seals began to replace packing on automobile water pumps. At first only the more expensive automobiles used mechanical seals in the water pump. The famous Jeep of WWII used a Crane rubber bellows seal in the water pump. After WWII, all automobile water pumps used mechanical seals.

During the mid 1940s, mechanical seals began to replace gland packing. Crane Packing Company developed its Type 1 and Type 2 rubber bellows mechanical seals in 1946. Because special lapping machines are required to manufacture mechanical seals, Crane Packing Company founded the Lapmaster Division.

In 1944, an amazing new material called Teflon (TM) was developed by Dupont. This material was relatively inert to many chemicals and held great promise for the sealing industry. To take advantage of the unique properties of Teflon, Crane developed the Type 9 (USA) and Type 109 (Europe) seals. In 1956, an all-PTFE acid-resistant seal, the Type 20, was launched.

During the late 1940’s and early 1950’s a number of the core product lines of Crane Packing Company were developed. In addition to the Type 1 and Type 2 rubber bellows seals and the Type 9 and 109 Teflon wedge seals, the well-known Type 8 family of seals was developed in this time frame. The Type 8 seal is an unbalanced seal for low pressures, the Type 8-B a high pressure seal for pipeline services and the Type 8B-1 is a very adaptable version of the Type 8-B for typical refinery and chemical plant services. Decades later, these seals (with modern materials and improvements, of course) are still among the most popular seals in the world.

In 1979, Crane Packing Company developed the Type 28 non-contacting, dry running gas seal to replace conventional oil lubricated seals then used on compressors. A patent was awarded for this unique mechanical seal which used spiral grooves to provide hydrodynamic lift and separate the sealing faces.

Amechanical seal is the most common type of sealing component used on pumps in modern industry. Replacing out packing over the last 50 or so years, they have served to drastically reduce industry emissions, energy usage and downtime globally.

A mechanical seal for pumps can be subdivided into variable options depending on the type/specific application/design components/location and mechanical seal characteristics;

The major advantage of a cartridge seal over a component seal is ease of installation. Incorrect installation is a major cause of seal failure, cartridge seals remove many of the problems associated with seal change-out in the field.

Slurry Seal – mechanical seal engineered to cope with a heavy slurry process – i.e. abrasive, corrosive and viscous. Can handle up to 60% slurrys by weight.

A Pusher Seal is where there is a spring element in the seal (used to maintain contact of the seal faces). Spring types include Belleville, multi-spring, etc. This type of seal requires a dynamic secondary seal.

A gas seal is a double seal where the barrier fluid is a gas – in pumps, this is usually a gas lift-off seal. In a gas lift-off seal the faces are not in contact while the machine is running. They are separated by a thin gas film (flow). If operated correctly they have very low wear.

The above seal types can be combined (though it is not always best to do so i.e. a component gas lift off seal would require very close collaboration between the machine and seal manufacturers to achieve a reliable installation).

There are many other options for mechanical seals, if you have any technical queries on other combinations not listed above, just contact one of our Mechanical Seal Specialists who will gladly discuss your application.

A mechanical seal flush is a piping set-up on a pump and seal assembly where a flow is induced in the seal chamber in order to improve MTBF of the mechanical seal. It is used to improve cooling, heating, remove solids and increase pressure (in combination with a neck or throat bush).

A mechanical seal quench is a piping set-up where a fluid is piped over the atmospheric side of a seal. It is generally used to prevent precipitation or crystallisation of a product or in some cases to aid cooling.

High Slurry process using Flowserve’s UNCD ® – Ultrananocrystalline diamond seal face technology. Flowserve UNCD ® coatings offer material properties and performance advancement over all other seal face materials.

Slurry seal design expertise applications which previously required double mechanical seals can now be reliably run by using single mechanical seals, saving costs of barrier fluid systems, the costs of the barrier fluid itself & the associated running costs. This reduces energy usage & carbon footprint.

If you have a technical query around the installation of mechanical seals for pumps or have some concerns around seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process running again.

Across the first half of the twentieth century the mechanical seal became the standard interface between the shafting arrangement inside the ship’s hull and the components exposed to the sea. The new technology offered a dramatic improvement in reliability and lifecycle compared to the stuffing boxes and gland seals that had dominated the market.

The development of mechanical seal technology continues today, with a focus on enhancing reliability, maximising product lifetime, reducing cost, simplifying installation and minimising maintenance. Modern seals draw on state-of-the-art materials, design and manufacturing processes as well as taking advantage of increased connectivity and data availability to enable digital monitoring.

Wärtsilä Shaft Line Solutions (SLS) has been at the forefront of this advancing technology for decades. Nowhere is its continuous investment in product quality more evident than in the evolution of the Wärtsilä Enviroguard M seal, the most widely used and highest performing mechanical seal across naval applications worldwide. Wärtsilä’s Enviroguard M seals have now been updated to further improve performance and value for naval customers. Highlighting the new features and developments shows exactly how far this technology has progressed.

Mechanical seals were a remarkable step forward from the previously dominant technology deployed to prevent seawater from entering the hull around the propeller shaft. The stuffing box or packed gland features a braided, rope-like material that is tightened around the shaft to form a seal. This creates a strong seal while allowing the shaft to rotate. However, there are several disadvantages that the mechanical seal addressed.

The packed gland remains a simple, failsafe option and is often still found in many engine rooms for backup. Should the mechanical seal fail, it can enable a vessel to complete its mission and return to dock for repairs. But the mechanical end-face seal built on this by boosting reliability and reducing leakage even more dramatically.

The revolution in sealing around rotating components came with the realisation that machining the seal along the shaft – as is done with packing – is unnecessary. Two surfaces – one rotating with the shaft and the other fixed – placed perpendicular to the shaft and pressed together by hydraulic and mechanical forces could form an even tighter seal, a discovery often attributed to engineer George Cooke in 19032 . The first commercially applied mechanical seals were developed in 1928 and applied to centrifugal pumps and compressors2 .

The US company John Crane was the first to apply mechanical seals to vehicles. In 1949, the company invented the first automotive mechanical seal. Wärtsilä acquired John Crane-Lips in 2002. Although the John Crane name did not transfer with the business, Wärtsilä gained several important brands, notably the Deep Sea Seals mark which is still known and respected in naval and commercial shipping. The US headquarters of John Crane was eventually to play a crucial role in the rise of Wärtsilä’s Enviroguard M seal when the company launched an ambitious push to serve the US Navy. As US legislation requires products to be supplied by an American company, John Crane served as a launchpad into the world’s biggest navy1 .

But the American expansion only came in the early 1980s. Long before then, as early as the 1950s, many of the conceptual designs and application guidelines that are in use today had been developed. Commercially available designs included both rotating and stationary flexible elements, balanced and unbalanced hydraulic loading, rubber and metal bellows, and a wide variety of spring designs and types. Various secondary sealing elements are available and the evolution in seal face materials has given rise to highly specific surfaces dependent on the application2 .

The history of Wärtsilä’s best-selling seal series, Enviroguard M, exemplifies the modern evolution of the mechanical seal in marine applications. Originally developed in the 1970s and at first known simply as the M-Series seal, the latest iteration of the range shows how several crucial features – face material, cooling/ flushing and condition monitoring – have developed over the years into today’s state-of-the-art stern tube seal.

The materials used for the stationary and rotating surfaces that press together to form the primary seal are among the most important considerations for mechanical seals. A balance must be struck between the cost of materials and their longevity, to prevent wear-down over time. Where water replaces oil lubrication, the face material needs to be able to cope with higher levels of abrasion, especially in waters containing sediment or other contaminants. This is particularly important for naval vessels operating in challenging environments, including coastal and tidal waters which may carry a high sediment load.

Having some abrasion resistance is paramount to improving durability and ensuring that seal faces remain responsive to the wear in the opposing face and thus maintain a tight seal. If the face material is too hard, any blemishes that occur to either face – for example if the face is damaged by sediment or by impact - will result in the seal leaking excessively. But with the right materials, the faces will wear just enough to maintain a tight fit however much the surfaces change over the lifetime of the seal.

In the late 1980s, the face material used in the Wärtsilä Enviroguard M series was changed to remove asbestos from the composite. That material, known as Manetex, was used for many years until the new design. Today the faces are made from an aromatic polyamide or ‘aramid’ composite material from the same family as the bullet-proof fibre Kevlar®. This material has been specially developed to enable the seal to perform in all environments, including brown water conditions.

Though the mechanical seal dramatically increased the reliability of the stern tube, the rise in naval demands over the years has led to further developments for increased reliability and reduced risk in the event of failure. With the Wärtsilä Enviroguard M seals, a back-up inflatable seal has traditionally provided redundancy, preventing water flow between the internal diameter of the stern tube and the external diameter of the propeller shaft in the event of a failure occurring in one of the blocking methods.

Building on that redundancy, the double inflatable barrier method mitigates against the highly unlikely event of primary seal failure, enabling afloat repair maintenance without cofferdams or divers. The latest double barrier design is easily accommodated, requiring only a slight increase in the length of the seal assembly in the design stage of the vessel, and significantly reduces the risk of compartment flooding and any subsequent vessel damage.

The first inflatable seal allows for the shaft to continue operating at reduced speed, even after main seal failure for a safe return to port; the second provides extra redundancy. Either of the seals can be used to keep the vessel moving or, when the shaft line is locked, to enable repairs and maintenance to be carried out afloat without the aid of divers. Minor overhauls of worn parts can also be managed in this way, which reduces the cost and complexity of maintenance by eliminating the need for dry dock.

Flushing is an important element of mechanical seals in naval applications. The primary purpose is to cool rotating components where constant friction would otherwise produce excessive heat and potentially damage the seal elements. In seals that are lubricated with water rather than oil, another important function of flushing is to prevent the accumulation of sediment or organic matter within the seal assembly. This material could cause early wear or even seize up rotating elements if unchecked.

The use of monitoring systems to control the volume and quality of water used for flushing was a recent step in making cooling seals more efficient. The flushing system itself has also evolved across the Wärtsilä Enviroguard M seal’s history.

In previous versions of the Wärtsilä Enviroguard M seals, water was channelled through the seal housing to the bearings. In the latest incarnation, a significant upgrade is direct flushing to the composite running face. By separating the bearing flush from the water used to flush and cool the seal, abrasive particles are kept away from the running face and more effective cooling is provided. This is another design feature that increases the lifecycle of the seal and minimises leakage.

Improvements to connectivity along with the rise of affordable sensor technology and powerful data analytic tools, have affected all areas of vessel machinery operation – mechanical seals are no different. While the inspection of seals remains mostly manual, today digital monitoring systems can alert crew – onboard or even onshore – about potential concerns. These functions can dramatically simplify maintenance and troubleshooting. The latest mechanical seals are designed to incorporate these advantages.

The renewed Wärtsilä Enviroguard M seals can come with optional temperature sensors for the purpose of identifying sealing interface faults. This optimises maintenance scheduling by telling operators how much running time they have left until an overhaul is needed. In many cases monitoring can alert operators of a condition which can be corrected to prevent premature seal failure. This reduces the risk of unexpected downtime and lowers maintenance costs due to the simplified procedure.

Although condition monitoring is becoming increasingly important, it should not entirely replace a manual inspection routine. Today the Wärtsilä Enviroguard M seals are built with the option for condition monitoring rather than it being offered as standard. But given the general naval demand for improved reliability and minimised downtime – as well as the very low cost of monitoring compared with the potential expense of seal failure – it is an option that is increasingly being adopted by naval customers.

The design iterations discussed above show how the Wärtsilä Enviroguard M seals have evolved as technology has advanced. The driving force behind these advances has been the increasingly stringent requirements of naval forces. These demands come in several forms, from safety, redundancy and shock resistance to ease of installation and maintenance as well as, increasingly, the availability of condition monitoring to enable predictive maintenance and early diagnostics.

Across all areas, Wärtsilä Enviroguard M has been designed to outperform expectations on the most challenging naval applications. That was the ethos when the range was first brought to the market 40 years ago and remains the same today, making it the leading series of water-lubricated mechanical stern tube seals in the marine market. The latest design upgrades position Wärtsilä Enviroguard to maintain that pedigree and continue outperforming expectations, well into the future

8613371530291

8613371530291