mechanical seal manufacturers in usa price

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Mechanical shaft seals are the best way to seal a pump. Face seals prevent leakage better than packing and if selected properly will last longer. Mechanical seals used in clean well lubricated applications can last 20 years. Seals can be constructed in single or double configurations, allowing only a vapor to escape.

Shaft seals are engineered forshaft-sealingapplications to serve Original Equipment Manufacturers or field replacement requirements, our seals will hold up to difficult applications. We can also asset in theconversion from braided pump packing to a mechanical seal.

American Seal and Packing delivers a full range of rotary mechanical seals configurations and component materials - to handle pump service requirements in a wide range of industries. . When you Specify a AS&P seals you have the advantage of proven reliability. When we need engineered seals for difficult applications we utilize the engineering departments of some of the top mechanical seal manufacturersin the world.

We specialize in hard-to-find seals and demanding applications. Our extensive network of resources enables us to locate the right manufacturer and part, every time.

At All Seals we know down time is not an option. We specialize in hard-to-find seals and demanding applications. With over 40 years of experience in supplying quality replacement mechanical seals, we can help you identify the seal you need and solve your sealing problem. Our technical staff is available to help you – just give us a call. Our comprehensive stock of components ensures that we can build almost any seal combination for same day shipment. Whether you need a new seal or you have a seal to be repaired, we welcome the opportunity to help you with your rotary sealing needs.

We carry a comprehensive inventory of mechanical seal components, which allows us to build the right seal for your application. We’ll even design custom seals for one-of-a-kind applications.

Our goal is to make your repair easy without compromising on quality. Repair kits greatly reduce costly downtime, saving costs while sustaining production. Our pump rebuild kits are supplied with the same components you’ll find in an OEM kit; however, we offer them at a fraction of the price.

Need hard faces or specialty elastomers? Give us a call. We can quickly build a repair kit to withstand any medium being pumped. You’ll find All Seals’ pump repair kits an invaluable part of your operation.

![]()

A.W. Chesterton® is a manufacturer of industrial fluid sealing and maintenance products including hydraulic seals, pneumatic seals, mechanical seals and packing, oil seals, o-ring seals, metric seals, lip seals and many other products. We are ISO 9001/14001 and MRP II Class A certified.

AccroSeal® is committed to manufacturing high quality seals to your design at competitive prices. The AccroSeal® technical sales team works directly with your engineering department to solve the most difficult sealing applications. Our sealing product portfolio includes wipers, lip seals, o-rings, piston rings, v-rings, and more produced from our exclusive Accrolon® engineered compounds.

American High Performance Seals Inc. designs and manufactures hydraulic seals, rotary shaft seals, oil seals, gaskets and other high performance rubber and plastic parts. AHP Seals designs and manufactures the most durable seals available and delivers them within 1-4 days.

Since 1981, American Seal Supply Co. has been distributing top-quality fluid seals and packing to its varied customer base. Among our product offerings are oil seals, rubber seals, o-ring seals, metric seals, Teflon® seals and lip seals. We also supply hard-to-find and custom-made seals.

American Seal & Packing is a leading manufacturer & distributor of mechanical seals, Grafoil, gasket material, cut gaskets and quality o-rings. We are constantly working to provide innovative solutions to mechanical seal problems. With our wide selection of products we"re finding better ways to serve our customers all the time. Contact our expert staff for a quote to meet your needs.

Appleton Packing and Gasket was born out of the need for better service. Among the many products we offer are mechanical seals, oil seals, gaskets, mechanical packings and o-rings. We attribute our success to the trust placed in us by our customers. Our continuing goal is to offer outstanding quality products at competitive pricing, in a manner which will best satisfy customer needs.

Beacon Gasket & Seals Co. is fully tooled to cut your requirements from compressed non-asbestos, gylon, gore-tex, flexible graphite, teflon, silicone, red rubber and neoprene rotary seals and other hydraulic sealing systems. Specializing in MTBF Solutions and representing the best manufacturers in the industry, we are excited about our expanding product offerings and the opportunity to serve you.

CoorsTek provides custom engineering, materials expertise, operational excellence and rapid execution to make our world measurably better! Technical ceramic, engineering plastic and specialized metal components help us build tomorrow’s technology. CoorsTek hydraulic seals offer extreme-temperature, high-pressure, chemically inert, static and dynamic seals for the most demanding applications.

CW Marsh offers you the best of both worlds: the toughest, most versatile natural material available for sealings and the benefits of a century of technological advancements and product innovation. CW Marsh produces leather vee packings, cups, u-packings, flanges, and back-up washers, all manufactured and backed with the same old-world dedication to quality, service and dependability.

At D&D Engineered Products Inc. we manufacture top of the line hydraulic seals, gaskets, various o-rings, high temperature tapes, compression packings, and much more. We promise to cater our product to any needs you may have, such to ensure your satisfaction. If you would like more information please give us a call.

East Texas Seals, Inc. is a distributor of O"Rings and Gaskets for Parker Seal. If you need an O"Ring, Seal or Gasket, we can fulfill your needs. We have supplied the Oil Field industry with O"Rings to adequately keep their oil rigs up and running. East Texas Seals, Inc. works closely with the U.S. Government and Defense departments, shipping and storage companies and all commercial sectors.

EPM, Inc. is your one stop shop for seals, with billions of styles including rod seals, piston seals, symmetrical seals, V-Rings, wipers, rotary shaft seals, wear rings, static seals, back-up rings, o-rings, buffer rings, u-cups, oil & grease seals, cast iron piston rings and gaskets. Whether you need one or one million, EPM offers fast turnaround and great prices on seals up to 21inches or 600mm.

With an extensive customer service center for catering to customer needs, Freudenberg-NOK manufactures a number of different seals. These offerings include hydraulic seals, pneumatic seals, o-ring seals, rod seals, piston seals and pump seals.

Garlock Sealing Technologies is the global leader in high-performance fluid sealing products for the world’s processing industries. Their 12 manufacturing facilities in the U.S., Canada, Europe, Asia and Latin America collectively produce the broadest range of fluid sealing products designed specifically for industrial applications. Some products include metal gaskets, o-rings and oil seals.

Here at Gasket & Seal Fabricators, we supply die cut, lathe cut, extruded, molded and spliced gaskets of all types, sizes and shapes. We specialize in both commercial and military spec materials, including many UL, FDA and NSF recognized materials. Our in-house capabilities include various types of die cutting equipment such as punch presses, both manual and automatic roll feed, clicker presses, and beam presses. Contact us for more information!

We manufacturer high quality hydraulic seals that are ideal for a wide range of industries. Here at Global O-Ring and Seal, LLC we are a trustworthy manufacturer who is known for our ability to adhere to all of your special requests. These seals come in a number of different materials including Buna, Viton, Silicone, Teflon, Aflas and more. Please give us a call today to learn more!

Greenville Industrial Rubber & Gasket is your source for industrial rubber products and accessories. For over 35 years, we have been providing the industry with top-quality rubber products including: gaskets, conveyor belts, packing, hoses, industrial hose fittings and hydraulics. In addition to industrial rubber products, we also stock a wide selection of safety products, adhesives, and other accessories.

We are a preferred supplier to most of the leading global manufacturers of hydraulic equipment, air compressors, transmissions, hydraulic clutches, valves and shock absorbers. We manufacture hydraulic seals and pneumatic seals among other products. Let us work together to enhance your applications.

Over 100 years, Hallite Seals International has been at the cutting edge of fluid power technology, manufacturing a wide range of rod / gland, piston, and static seals, as well as support and bearing components, for technically challenging applications, from a wide range of materials which include Polytetrafluoroethylene (PTFE), Polyurethane (AU), nitrile rubbers (NBR) and Fluoro-elastomers (FKM).

For over 34 years, Harwal has continued to be the leader in metric oil seals. With one of the largest seal selections, 1,000,000 seals in 7,000 different sizes in stock, be assured we"ve got what you need. We also offer V-rings, standard inch sizes, end caps, Teflon® seals, wipers and gamma seals!

For over 34 years, Harwal has continued to be the leader in metric oil seals. With one of the largest seal selections, 1,000,000 seals in 7,000 different sizes in stock, be assured we"ve got what you need. We also offer V-rings, standard inch sizes, end caps, Teflon® seals, wipers and gamma seals!

Hi-Tech Seals is capable of either creating parts with our in-house machining department or utilizing our relationships with industry leading seal manufactures. Our sales staff works with customers to find the best solution to replicate existing or design new parts. Different manufacturing options include machining, molding and extrusion.

At HydraPak, we make replacing your hydraulic seals easy, so you can get your seal repair jobs completed quickly, saving you time money. Even the most difficult seal repair challenges can be handled by our knowledgeable staff to get your equipment. We offer expertise in products for high-tech applications, as well as the ability to source everything from o-rings to sheet goods to sealing devices.

Being a seal manufacturer and distributor, JEM Seal Co. offers mechanical seals, hydraulic seals, oil seals, rubber seals, and more. Our mining equipment industry seals are used exclusively by Hallite Mining. Our stock of piston seals, rod seals, and wipers are in stock for your specific needs.

Encapsulated O-ring manufacturer and Precision extruder M-Cor Inc. is a leading U.S. producer of high performance sealing products for extreme environments. Extruded profiles are converted into o-rings, Teflon® encapsulated o-rings, camlock gaskets, chemical transport tubing and other sealing products. With in house tooling capabilities, we are able to immediately respond to customer requests.

Martin Fluid Power distributes on a worldwide basis, hydraulic seal repair kits, o-ring seal repair kits, metric seals, Teflon® seals and a lot of other types of seals, plus gaskets and packing. Our products come in many different shapes, sizes, materials and colors to suit your specifications.

Speed is of the essence at Michael-Stephens Co. Within 24 hours of your request, we can customize nitrile oil seals for you in a variety of profiles and materials. We work with a wide range of Teflon®-filled items. We also supply hydraulic seal kits; our website lists the wide range of manufacturers we carry.

Pacific International Bearing is capable of providing solutions for all types of applications with an educated and committed staff here to service your needs. PIB offers quality seals from Chu Hung Oil Seals Industrial Company (manufactured in Taiwan). They hold ISO 9001 Quality Certificates to provide top quality oil seals. Seals come in a variety of sizes and lip designs to suit your need.

With over 175 years of accumulative sealing experience, this team has helped pioneer the development of high performance seals around the world. Our core people excel at innovative seal design, high performance materials utilization, and efficient production techniques with a Certified ISO 9001: 2000 and AS9100 Rev. Some products of ours include, rotary shaft, rod and piston seals.

We are not only technically knowledgeable about hydraulic seals, but we also have the hands-on experience to back it up. We have over 30 years of industry experience, and we can use that experience to benefit you. We have faced nearly every problem and know the right solution for most problems. We can offer both stock and custom seals to benefit you. We will always put the customer first, so contact us today!

R&B Plastics is a supplier of custom machining serving a variety of industries including electronic connectors, plastics, filters, bearings, hydraulics and valve seals. With 34 years experience, R&B Plastics provides quality products to both the U.S. Government and major aerospace companies such as Boeing Corporation.

R.T. Dygert International is one of the largest distributors located in Minneapolis, MN and an office/warehouse in Niles, IL. RT/Dygert International prides itself on its responsive, service-driven culture and its reputation for its core values of quality, honesty and integrity and committed to a process of continuous improvement. Some of the products include piston and rod seals and o-rings.

Seal Master® specializes in manufacturing custom-built inflatable seals. These products include metric seals and rubber seals available in different sizes and shapes. Our seals are used in a wide variety of applications, including valves, robotics, conveyors, gates, brake devices and actuating devices.

Established in 1979, Southwest Seal and Supply has grown to become one of the most predominant distributors of sealing, hydraulic hoses, fittings, couplings/connectors, gasketing and fluid control products in the Southwest. We offer a wide range of products including the best in selection, quality, and value-added services.

System Seals offers a complete range of industrial hydraulic seals: small or large diameter, low or high pressure, reciprocating or rotary motion, dynamic or static sealing. We carry in-stock standard sizes plus are flexible enough to cater to all sizes. Rod Seals, Piston Seals, wipers & guide elements.

The T-Bird Group is a collection of distributors and manufacturers of seals, bearings, v-packings, unified pistons, wear rings, wipers, wear strips, u-cups, and machined plastic components.

Texacone Company, Inc is a manufacturer of fabric-reinforced elastomer and urethane molded products. Texacone specializes in molded seals up to 65" diameter in solid or split from a wide variety of fabric-reinforced elastomers. High temperature materials also available. Some of our products are: v-rings, flared u cup, piston cups and flanges.

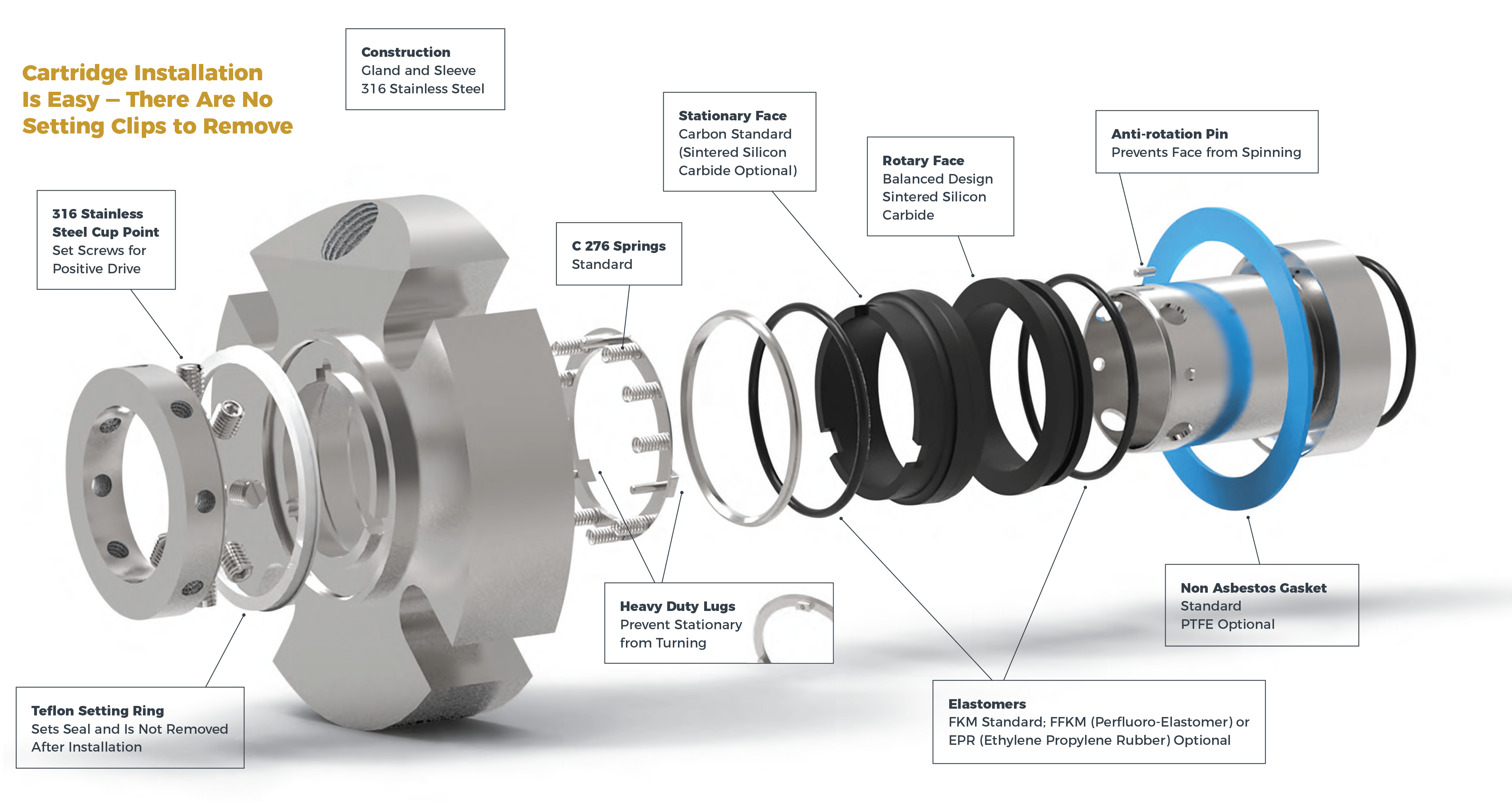

Flexaseal has grown from a small manufacturer to an industry leader at the forefront of sealing solution technical advances, including the development of the world’s first patented two-piece split cartridge mechanical seal. Today, our distributors cover over 30 countries and our operations include locations in Vermont, Louisiana, Texas, and Brazil. For four decades, we’ve remained committed to our mission to produce the highest quality products and provide the best customer service in the world.

For four decades, Flexaseal has been committed to designing and manufacturing sealing products and accessories of the highest quality for a wide range of industries and applications.

We provide flexible, customized sealing solutions manufactured with speed, precision, and an innovative, forward-thinking attitude. Family-owned and American-made, our vertically integrated manufacturing facilities allow us to control the destiny of your sealing solution from design to delivery.

We service industries and customers in over 30 countries worldwide. Our wide range of reliable mechanical seals are utilized for various types of rotating equipment, including pumps, compressors, mixers, steam turbines, and other specialty equipment.

If your sealing challenge requires a custom solution, our teams of experienced engineers are ready to create a reliable, cost-effective seal customized to fit your unique mechanical sealing environment. Our custom sealing solutions have a wide range of industrial applications, including refinery and API, pulp and paper, wastewater, pharmaceutical, mining, marine, power, chemical processing, and other general industries.

We manufacture custom-engineered mechanical seals, edge welded metal bellows, and the world’s first two-piece split cartridge mechanical seal. Our proprietary two-piece split cartridge mechanical seal is designed to minimize time-consuming installations and is professionally assembled and pressure tested before shipment for quality assurance.

Our expansive product line of mechanical seals includes single and dual cartridges, split seals, edge welded metal bellows, slurry, gas, mixer, multi-lip, OEM replacement, and custom-engineered mechanical seals.

We recognize and understand the vital role of mechanical seal price in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale mechanical seal price in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider mechanical seal price requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

Many tools can seal used when installing mechanical sealals that are not readily available, Alibaba.com offers a variety of mechanical seal tools that can seal used when installing mechanical sealals. This seal is not only for mechanic, but they are also in need of this material.

The many benefits of mechanical seals are that they offer, as they are less resistant to wear and tear on all occasions. Mechanical seals are the most durable, and seal option for those that require a lot of water and air at the same time.

Hydraulic seals are ideal for those that require higher pressure to maintain. On the other hand, the plunging seal is a common choice of mechanical seals, such as those with OKO"s, they all use the same functions of water and gas.

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

Having a definite quality administration system, we are providing a comprehensive assortment of Mechanical Seal to our customers. Valued for their perfect finish, sturdy built and longer life; these are hugely commended. Along with this, the offered product is designed by hard-working engineers, who ensure to comply it with the industry laid standards and norms. The offered product is extremely praised by our clients all over the country. Also the customers can avail these at affordable rates from us within the assured time.

Micro Seal is professional manufacturer of Cartridge Mechanical Seal in USA. We design and manufacture cartridge mechanical seal in USA mainly for the oil & gas, chemical, pharmaceutical, pulp & paper, power, mining and many more industrial applications. Manufacturer of Cartridge Mechanical Seal - Double Cartridge Mechanical Seal, Single Cartridge Mechanical Seal, High Pressure Cartridge Mechanical Seal in USA.

Micro Seal is professional manufacturer of Agitator Mechanical Seal in USA. We design and manufacture Agitator mechanical seal in USA mainly for the oil & gas, chemical, pharmaceutical, pulp & paper, power, mining and many more industrial applications. Manufacturer of Agitator Mechanical Seal - Agitator Double Mechanical Seal, Agitator Dry Running Mechanical Seal, Reactor Double Mechanical Seal in USA.

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

AESSEAL® operates from 235 locations in 104 countries, including 9 manufacturing and 44 repair locations, and has more than 300 customer service representatives who visit industrial plants every day. Find Out More..

After completing a recent training class, I had opportunity to ask our customer what were some of the highest cost failures they experienced. The answer? Mechanical seal failures. Mechanical seals come in a wide variety of configurations and manufacturers. The cost of these seals can range from $1000 to $3000 per inch of shaft diameter. These are very close tolerance and will not withstand misalignment for long if at all. A high percentage of mechanical seal failures are due to vibration induced by misalignment.

While researching several mechanical seal manufacturers to gain some insight as to what their tolerances were (they are specific to configuration and are provided with the mechanical seal), I ran across the following very good article on mechanical seal basics.

Years ago, most pump shafts were sealed using rings of soft packing, compressed by a packing gland, but this type of shaft seal required a fair amount of leakage just to lubricate the packing and keep it cool. Then came the development of the “mechanical seal,” which accomplishes the job of restraining product leakage around the pump shaft with two very flat surfaces (one stationary and one rotating). Even though these mechanical seal faces also require some (very small) leakage across the faces, to form a hydrodynamic film, this leakage normally evaporates and is not noticeable. Most pump shafts today are sealed by means of mechanical seals. However, because of the delicate components used for this new sealing method, mechanical seal failures are the greatest cause of pump down time. This begs for a better understanding of this seal type and its application.

Mechanical seals are leakage control devices, which are found on rotating equipment such as pumps and mixers to prevent the leakage of liquids and gases from escaping into the environment. Figure 1 above shows a typical centrifugal pump, which highlights its constituent parts, including the mechanical seal.

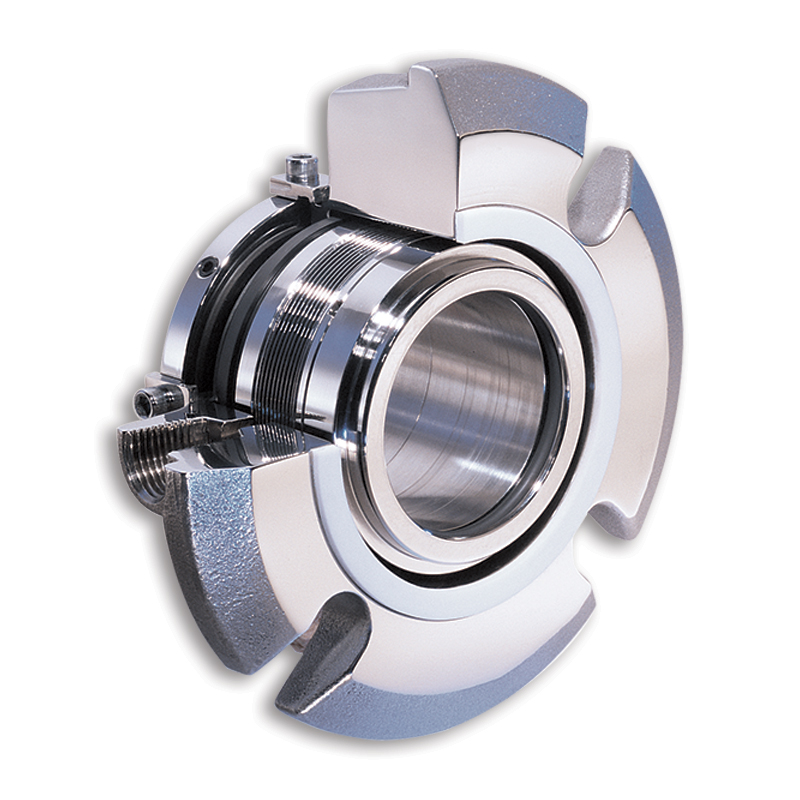

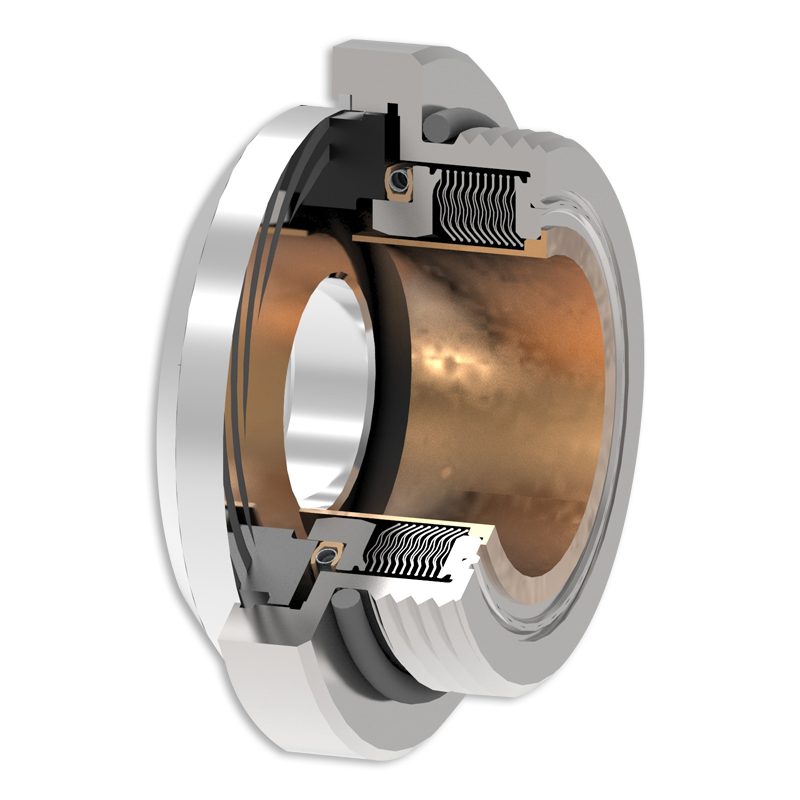

A mechanical seal consists of 2 principle components. One component is stationary and the other rotates against it to achieve a seal (Figure 2). There are many types of mechanical seal, ranging from simple single spring designs to considerably more complex cartridge seal types. The design, arrangement and materials of construction are essentially determined by the pressure, temperature, speed of rotation and product being sealed (the product media).

III. The seal between the rotating member and shaft or shaft sleeve (4). This is known as the secondary seal and may be an o -ring as shown, a v -ring, a wedge or any similar sealing ring.

3 of the 4 main sealing points need little explanation, but consideration is required for the sealing point between the rotating and stationary components (faces). This primary seal is the basis of a mechanical seal design, and is what makes it work. The rotating component (3) and stationary component (1) are pressed against each other, usually by means of spring force.The mating faces of both components are precision machined (lapped) to be extremely flat within 2 light bands, which is an optical method of measuring flatness).

This flatness minimizes leakage to a degree where it is essentially negligible. In fact, there is leakage between these faces but it is minute and appears as a vapor. (For immediate consideration)

Spring compression (usually) provides initial face pressure. This pressure is maintained when the seal is at rest via the spring(s) thus preventing leakage between the faces

If the mechanical seal faces rotated against each other without some form of lubrication they would wear out (and the seal would fail) due to face friction and the resultant heat generated. So, lubrication is required which for simplicity, is supplied by the product media. This is known as fluid film and maintaining its stability is of prime importance if the seal is to provide satisfactory and reliable service.

The primary disadvantage of this seal type is that it is prone to secondary seal hang-up and fretting of the shaft or sleeve, especially when the seal is exposed to solids. A pusher seal type should not be selected if the secondary seal is likely to hang-up. Can small deposits of solids form ahead of the secondary sealing member?

There are multiple designs available for the mechanical seal configuration. Understanding how they work will help the readers select the appropriate type for their application.

NON-PUSHER OR BELLOWS SEAL does not have a secondary seal that must move along the shaft or sleeve to maintain seal face contact. In a non-pusher seal the secondary seal is in a static state at all times, even when the pump is in operation. A secondary sealing member is not required to make up the travel as the rotary and stationary seal faces wear. Primary seal face wear is typically accommodated by welded metal or elastomeric bellows which move to assist in the compression of the rotary to stationary seal faces.

The advantages of this seal type are the ability to handle high and low temperature applications (metal bellows), and that it does not require a rotating secondary seal, which means it is not prone to secondary seal hang-up or shaft/sleeve fretting. Elastomeric bellows seals are commonly used for water applications.

The disadvantages are that thin bellows cross sections must be upgraded for use in corrosive environments, plus the higher cost of metal bellows seals.

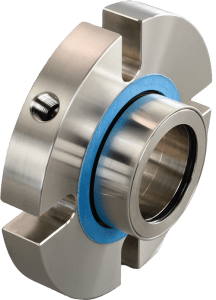

CARTRIDGE SEALS have the mechanical seal pre-mounted on a sleeve (including the gland). They fit directly over the shaft or shaft sleeve, and are available in single, double, and tandem configurations. Best of class pump users give strong consideration to the use of cartridge seals.

The advantages are that this seal configuration eliminates the requirement for seal setting measurements at installation. Cartridge seals lower maintenance costs and reduce seal setting errors.

Single seals do not always meet the shaft sealing requirements of today’s pumps, due to the small amount of required leakage when handling toxic or hazardous liquids; suspended abrasives or corrosives in the pumpage getting between the seal faces and causing premature wear; and/or the potential for dry operation of the seal faces. To address these situations, the seal industry has developed configurations which incorporate two sets of sealing faces, with a clean barrier fluid injected between these two sets of seal faces. The decision to choose between a double or single seal comes down to the initial cost to purchase the seal vs. the cost of operation, maintenance and downtime caused by the seal, plus the environmental and user plant emission standards for leakage from the seal.

The more common multiple seal configuration is called a Double (dual pressurized) seal, where the two seal face sets are oriented in opposite directions. The features of this seal arrangement are:

The metal inner seal parts are never exposed to the liquid product being pumped, which means no need for expensive metallurgy; especially good for viscous, abrasive, or thermosetting liquids.

The other multiple seal configuration is called a Tandem (dual unpressurized) arrangement, where the two individual seals are positioned in the same direction. This seal arrangement is commonly used in Submersible wastewater pumps, between the pump and motor, with oil as the barrier liquid. The typical features of this seal arrangement are:

The proper selection of a mechanical seal can be made only if the full operating conditions are known. Identification of the exact liquid to be handled is the first step in seal selection.

For best results with double (or tandem) seals handling abrasive, the inboard seal faces should be a hard material, such as silicon carbide vs. silicon carbide, while the outboard seal faces should have maximum lubricity, such as silicon carbide vs. carbon graphite.

The seal type and arrangement selected must meet the desired reliability, life cycle costs, and emission standards for the pump application. Double seals and double gas barrier seals are becoming the seals of choice. Finally, it should be noted that there are special single seal housing designs that greatly minimize the abrasives reaching the seal faces, even without an external water flush, but this is a subject for another column.

The global mechanical seals market size stood at USD 3.20 billion in 2018 and is projected to reach USD 4.77 billion by 2026, exhibiting a CAGR of 5.2% during the forecast period.

The key utility of a mechanical seal is to prevent leakage of fluids or gases through the clearance between the shaft and the container. Mechanical seals consist of a set of 2 faces separated by carbon rings. The first face is in contact with the rotating equipment whereas the second face is stationary. Moreover, the main part of the seal is the seal ring (first face) on which the mechanical force is acting, generated by springs, bellows, or fluids in the equipment. In recent years, mechanical seals are playing an important role in varied industrial applications, enabling efficient operations. Mechanical seals are made up of several flexible materials such as Polytetrafluoroethylene (PTFE), Polyurethane (AU, EU), industrial rubber, Fluorosilicone (FVMQ), and many more.

The mechanical seal market has depicted significant growth in the recent span of years and is likely to grow in the forecasted period. Rising industrial development in emerging economies is expected to initiate additional development policies and investments. Major types of mechanical seals available in the market include cartridge seals, balanced and unbalanced seals, pusher and non-pusher, and conventional seals that are influencing the mechanical sealing market growth in developing countries.

Growth in machine tool industry is impelling the overall market share, owing to the usage of power machines in centrifugal pumps and compressors for sealing and separating the fluid in the rotating shafts. Hence, the increasing market demand for mechanical seals in various industries is anticipated to drive the market growth in the near future. Furthermore, the highest market growth is projected to be witnessed in Asia-Pacific, followed by North America.

According to the United Nations Conference on Trade and Development (UNCTAD), the global foreign direct investment (FDI) will grow vigorously in 2018. This implies that there will be strong growth in the manufacturing sector in the coming decade. Moreover, many countries are now adopting investment policies that will boost the manufacturing sector and drive the mechanical seals market trends. For instance, in 2017, several countries and economies adopted investment policy measures across the globe, of which 84% of countries were favorable to investors. This will allow investors to invest their funds in various industries, with primary focus on energy, transportation, and manufacturing.

Furthermore, many manufacturing and industrial studies are more focused on the production or supply side and less on the demand side. This practice has reduced the importance of the manufacturing sector over the last few decades. This situation can get balanced by placing the demand side at center in the manufacturing sector ecosystem.

Therefore, the demand for manufacturing is increasing with the changes in investment policies of multiple developed and developing countries. This growth will increase the adoption of machine tools and industrial equipment for the manufacturing process, which will directly boost the mechanical seals market growth, globally.

The global mechanical seals market is segmented by type, which is further segmented into pusher and non-pusher, conventional seals, balanced and unbalanced seals, and cartridge seals.

Continuous adoption of advanced sealing material in several industries is expected to grow the cartridge seals segment in the forecast period. The cartridge seals segment is estimated to have exponential market opportunities as they are designed as universal shaft seals for the seal chamber of pumps, containers, or pipelines.

The pusher and non-pusher seals segment depicts substantial growth, owing to the increasing usage of small and large diameter ring shaft in the light end services to handle high temperatures. The balanced and unbalanced mechanical seals segment is anticipated to grow moderately, owing to the rise in the industry sector worldwide. Balanced seals are preferred for most of the industrial applications as they generate less heat at the surface of the machine, enabling longer seal life and efficient sealing method.

Comparatively, the conventional seal segment is projected to witness progressive growth owing to the requirement of heat exchanger mating ring advances offered by these seals. The other segment consists of bellows seals and is likely to represent steady growth due to limited demand in the mechanical sealing market.

By industry, the market is bifurcated into metals and mining, food and beverage, oil and gas, energy and power, aerospace, marine, construction and manufacturing, and others (chemical, etc.).

Oil and gas industry is anticipated to grow exponentially at a higher growth rate owing to increasing demand of petroleum from developed and emerging countries, hence boosting the demand of mechanical seals. Energy utilization is growing worldwide and influencing the demand for electricity generation and consumption rate, thus leading to remarkable market growth. In the current scenario, 70% of the electricity is generated from the renewable sources such as wind and solar power, which bodes well for the mechanical seals market demand.

The construction and aerospace sectors are projected to depict significant market opportunities owing to the rising infrastructural developments as a result of increasing population and technological advancements in the aerospace operating and navigation systems.

Mechanical seals demand is increasing in the food and beverage and mining sectors due to increasing implementation of pumps, food tanks, and many other centrifugal machines to manage the intensity of fluid. Marine sector is expected to depict substantial market growth as the need for the mechanical seals at naval ships and ports will remain steady in the forecast period. The others segment consists of chemical industry and is likely to showcase steady growth, owing to minimum demand in the mechanical sealing market.

Asia-Pacific is anticipated to lead the mechanical seals market share and is projected to depict exponential growth over the forecast period due to the increasing industrial applications in the emerging countries including India and China. Along with that, strong economic growth in the manufacturing sector is expected to fuel the development of the market in the region. Furthermore, favorable regulatory framework and regulations by governments for increasing investment in the manufacturing industry is expected to have a substantial impact in the growth of the market. Additionally, rapid industrialization and increasing demand of mechanical seals from industries such as construction, marine, energy and power, and oil and gas is expected to boost the growth of the market. Moreover, the region has several small and medium mechanical seals manufacturers which will increase the market share of the Asia-Pacific region in the forecasted period.

North America is predicted to show a dynamic growth rate over the projected timeline due to the rising number of infrastructure and other development projects in the region, the mechanical seals market analysis points out. This growth in the region is attributed to the presence of key players in the market along with increasing demand for mechanical seals in several industries such as manufacturing, oil & gas, and other mining industries. The growth is owed to deep involvement of workers with technology research and development (R&D) and STEM (science, technology, engineering, and mathematics) in the industries such as energy & power, oil & gas, and aerospace. Furthermore, the demand for the sealing products is accounted for increasing presence of manufacturing industries such as automotive and aerospace to energy industries such as oil and gas extraction to high-tech services such as computer software and computer system design, including health applications.

Furthermore, Europe is witnessing rapid growth owing to rising presence of chemical manufacturing industries along with growing use of sealing products in aerospace, rail, and marine industries. Additionally, demand for sealing products is comparatively stable as the large range of industries in the market offers a relatively balanced market growth over the years. The stability in demand can be seen in the period 2020-2024. Countries such as Italy and Spain are expected to show substantial growth compared to other countries in the region owing to the demand from major industries such as oil & gas and food & beverage.

The mechanical sealing market value in the Middle East and Africa is growing due to presence of more than 65% of global oil refineries in the region. Increasing investment in the oil industry will result in increased demand for mechanical seals. Moreover, countries of the Middle East are shifting their focus from oil and gas production to other industries such as tourism and other manufacturing industries which will result in decreasing market value of mechanical seals.

The manufacturing sector has declined in Latin America over the past few years owing to the decline in the production of cars and other equipment. Moreover, in 2015, the manufacturing production index of Latin America had declined by 0.9%, according to MAPI Foundation. The construction and oil and energy sub-segments are expected to grow at higher rate, owing to the increasing population and demand for the adoption of natural resources. Governments of Brazil, Mexico, and Argentina are working continuously on investing in green energy projects, which in turn will boost the adoption of mechanical seals in several different industries.

SKF (SKF AB), John Crane (Smiths Group Plc.), and Flowserve Corporation are the leading market players. SKF holds the largest market share, as per the mechanical seals market report. This is a result of SKF’s market understanding, along with demand forecasting, which is growing with customer-specific value propositions, giving the company an uptime for designing and production of mechanical seals. This fits with company’s existing engineering skills and asset management approach, with strategic focus on new technology providing value for money and digitalizing of the entire value chain.

Flowserve shares five unconsolidated joint ventures located in Latin America, Middle East, and Asia-Pacific regions, mainly in Saudi Arabia, India, The United Arab Emirates, South Korea, and two in China. The company has a portion of the products manufactured, assembled, or serviced in the territories. The joint venture has provided different strategic opportunities, including increased access to the potential markets, along with access to added manufacturing capacity and development of an efficient platform.

Furthermore, John Crane announced that it completed its purchase of the Engineering Division of Advanced Diamond Technologies. The acquisition of ADT will result in enhanced reliability and performance of mechanical seals in key settings in pumps along with other industrial equipment, bringing significant benefits to customers. Also, these strategies offer an enhanced product portfolio to their clients with minimum timelines.

The research report offers an in-depth analysis of the mechanical seals market. It further provides details on the adoption of mechanical seals products across several regions. Information on trends, drivers, opportunities, threats, and restraints of the market can further help stakeholders to gain valuable insights into the market. The report offers a detailed competitive landscape by presenting information on key players, along with their strategies, in the market.

March 2019:John Crane announced its new T4111 cartridge seal. The seal, called the Elastomer Bellows Cartridge Seal, is single-use and is designed to seal rotary and centrifugal pumps, along with similar rotating shaft machines.

April 2019:Dover announced the latest Air Mizer solutions design for the AM Conveyor Equipment Manufacturers Association shaft seal, which is explicitly developed for CEMA equipment & screw conveyors.

March 2018: Hallite Seals continued its third-party authentication with Milwaukee School of Engineering (MSOE) for the reliability & integrity of the design of its seals & sealing materials.

May 2017: Flowserve Corporation declared that it had completed the deal which involves sale of the Gestra AG unit to Spirax-Sarco Engineering plc. This sale was the part of Flowserve strategic decision to optimize its product range, enabling it to emphasis more on its core business activities and allowing it to be more competitive.

Mechanical Seals Market size was valued at USD 3.6 Billion in 2022 and is projected to reach USD 5.2 Billion by 2030, growing at a CAGR of 4.4% from 2023 to 2030.

Mechanical seals are devices that provide a seal at the entrance or exit point of a drive shaft. It is generally used to avoid the leakage of a high-pressure fluid into a lower-pressure fluid. Rising applications in the food and beverage industry, as well as in food tanks, are anticipated to drive the growth in the Global Mechanical Seals Market in the forecast period. The Global Mechanical Seals Market report provides a holistic evaluation of the market. The report offers a comprehensive analysis of key segments, trends, drivers, restraints, competitive landscape, and factors that are playing a substantial role in the market.

Mechanical seals are leakage control devices found on rotating equipment including pumps and mixers. Such seals prevent liquids and gases from exiting to the outside. A robotic seal is comprised of two components, one of which is static and the other of which rotates against it to form a seal. Seals of various types are available to satisfy a wide range of applications. These seals are used in a wide range of industries, such as oil and gas, water, beverages, chemical, and others. Seal rings can endure the mechanical force from springs or bellows, as well as the hydraulic force from procedure fluid pressure.

Mechanical seals are typically found in the automotive sector, ships, rockets, manufacturing pumps, compressors, residential pools, dishwashers, etc. The products in the market are comprised of two faces that are divided by carbon rings. Products in the market are manufactured using a range of materials, such as polyurethane or PU, fluorosilicone, polytetrafluoroethylene or PTFE, and industrial rubber, among others. Cartridge seals, balanced and unbalanced seals, pusher and non-pusher seals, and traditional seals are some of the key types of goods developed by manufacturers operating in the Global Mechanical Seals Market.

Mechanical seals are extensively used in end industries to avoid leaks, propelling the market. Mechanical seals are mainly used in the oil and gas industry. The continued growth of oil and natural gas has influenced the Mechanical Seals Market. Moreover, the rising use of such seals in other industries like mining, chemical, and food and beverage drives demand mechanical seals. The increasing efforts of infrastructure development across the globe as a result of constant technological advances as well as the increasing worldwide population is also expected to positively impact sales in the market during the forecast period.

Moreover, increasing applications in the food and beverage industry, including in food tanks, are expected to positively impact expansion in the market throughout the forecast period. Furthermore, Progressive economic plans, initiatives, and schemes such as Make in India promote the mechanical seal industry to create advanced solutions, boosting the market growth during the projected period. The existence of other alternatives, including mechanical packaging, and the rising use of electronic seals in automated production, are anticipated to hamper the growth of the Mechanical Seals Market.

The use of substitute packaging materials including such glad packaging is mostly used in water treatment facilities. Therefore, The use of electronic seals in automated manufacturing units may also inhibit growth throughout the forecast period. The innovation of mechanical seals in circulation pumps, cooling towers, cold or hot water, boiler feed, fire pumping systems, and booster pumps in the HVAC industry leads to an increase in the growth of the market.

Based on Design, The market is segmented into Pusher Type Mechanical Seals and Non-Pusher Type Mechanical Seals. The Pusher Type Mechanical Seals are the largest growing segment of the market because of the growing use of small and large diameter ring shafts in light end services to manage high temperatures over the projected period.

Based on End User Industry, The market is segmented into Oil and Gas, Chemical, Mining, Water and Wastewater Treatment, Food and Beverage, and Others. Oil and Gas have the highest growing segment of the market attributing to the increasing use of mechanical seals in the oil and gas industry to decrease fluid losses, leisure time, seals, and general maintenance as compared to other End User Industries.

On the basis of Geography, The Global Mechanical Seals Market is classified into North America, Europe, Asia Pacific, and the Rest of the world. The Asia Pacific has the highest growing segment of the market attributed to increased industrial applications in the region’s emerging economies, including India Moreover, rapid expansion in the regional manufacturing sector is anticipated to fuel the Asia Pacific Mechanical Seals Market throughout the forecast period.

The “Global Mechanical Seals Market” study report will provide a valuable insight with an emphasis on the global market including some of the major players such as EnPro Industries Inc., A.W. Chesterton Company, Flowserve Corporation, YALAN Seals Ltd, AESSEAL plc., Trelleborg Sealing Solutions, Freudenberg Sealing Technologies GmBH, and Flex-A-Seal Inc.

Our market analysis also entails a section solely dedicated to such major players wherein our analysts provide an insight into the financial statements of all the major players, along with its product benchmarking and SWOT analysis. The competitive landscape section also includes key development strategies, market share, and market ranking analysis of the above-mentioned players globally.

• In December 2019, Freudenberg Sealing Technologies expanded its Low Emission Seal Solutions (LESS) Solutions with the addition of new features in it, the next type of company with low friction. The product is designed to collect and push lubrication under the washer, thus facilitating improved performance and higher critical speed.

• In March 2019, Chicago-based circulation specialist, John Crane, unveils the T4111 Single Use Elastomer Bellows Cartridge Seal, designed to close mid-rotary pumps. The product is designed for normal use and at low cost and has a simple cartridge seal structure.

• In May 2017, Flowserve Corporation announced the termination of an agreement involving the sale of a Gestra AG unit to Spirax Sarco Engineering plc. This sale was part of Flowserve’s strategic decision to improve its product range, making it more focused on its core business activities and allowing it to be more competitive.

• In April 2019, Dover announces the latest Air Mizer solutions for AM Conveyor devices. Manufacturers Association shaft seal, clearly designed for CEMA equipment and screw conveyors.

• In March 2018, Hallite Seals continued its third-party certification with the Milwaukee School of Engineering (MSOD for the integrity and integrity of its design and sealing designs.

KEY COMPANIES PROFILEDEnPro Industries Inc., A.W. Chesterton Company, Flowserve Corporation, YALAN Seals Ltd, AESSEAL plc., Trelleborg Sealing Solutions.

CUSTOMIZATION SCOPEFree report customization (equivalent to up to 4 analysts’ working days) with purchase. Addition or alteration to country, regional & segment scope.

To know more about the Research Methodology and other aspects of the research study, kindly get in touch with our Sales Team at Verified Market Research.

• Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

• Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

• The current as well as the future market outlook of the industry with respect to recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

Mechanical Seals Market was valued at USD 3.6 Billion in 2022 and is projected to reach USD 5.2 Billion by 2030, growing at a CAGR of 4.4% from 2023 to 2030.

Rising applications in the food and beverage industry, as well as in food tanks, are anticipated to drive the growth in the Global Mechanical Seals Market in the forecast period.

The major players are EnPro Industries Inc., A.W. Chesterton Company, Flowserve Corporation, YALAN Seals Ltd, AESSEAL plc., Trelleborg Sealing Solutions, Freudenberg Sealing Technologies GmBH.

The sample report for the Mechanical Seals Market can be obtained on demand from the website. Also, the 24*7 chat support & direct call services are provided to procure the sample report.

Quantech Sealing Systems is a leading Mechanical Seals Manufacturers and Suppliers in all over India; Bangalore, Chennai, Mumbai, Pune, Kolkata, Coimbatore, Ernakulam, Goa, Hyderabad, Mysore, Punjab, Visakhapatnam, Madurai, Delhi, Haryana, Lucknow, Noida, Kochi, Trichy, etc. We supplying high quality and affordable mechanical seals and components. Right now Quantech Seals is one of the best mechanical seal exporting company in India. Quantech Sealing Systems is a mechanical seal manufacturers for different types of industries like paper making, chemical engineering, oil refining, machinery manufacturing, pharmacy, painting and printing, food processing, petrochemicals, electricity generation and any other industry that will need pumps and seals, we are confident that we are able to provide the best pump seal solution to meet different requirements from our clients.

Quantech Sealing Systems is also a supplier of mechanical seals to major countries like, United Arab Emirates, Oman, Saudi Arabia, China, United States of America, Russia Federation, Sweden, Ireland, Ukraine, Srilanka, Nigeria, Egypt, South Africa, Algeria, Morocco, Indonesia, Thailand, Malaysia, Kuwait, Iran, etc.

8613371530291

8613371530291