aes mechanical seal manufacturer

![]()

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

AESSEAL® operates from 235 locations in 104 countries, including 9 manufacturing and 44 repair locations, and has more than 300 customer service representatives who visit industrial plants every day. Find Out More..

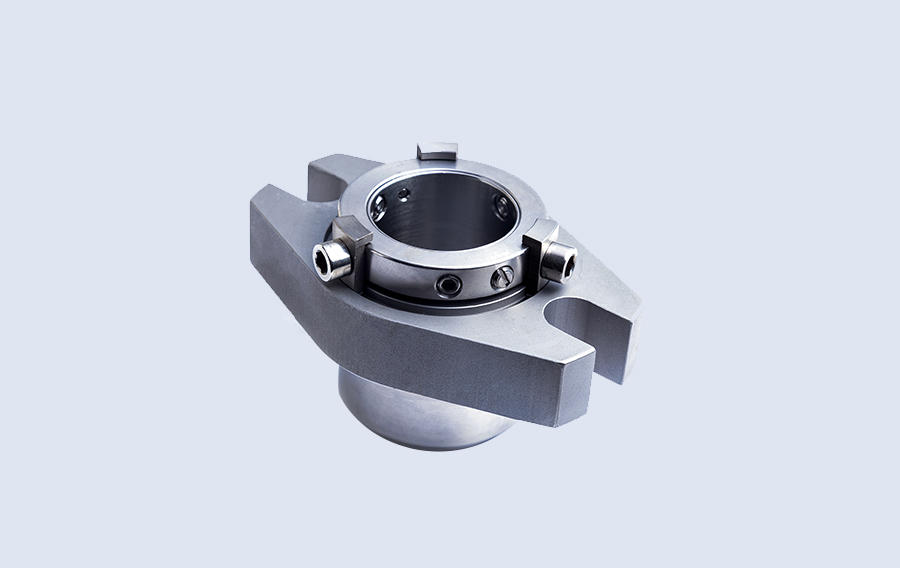

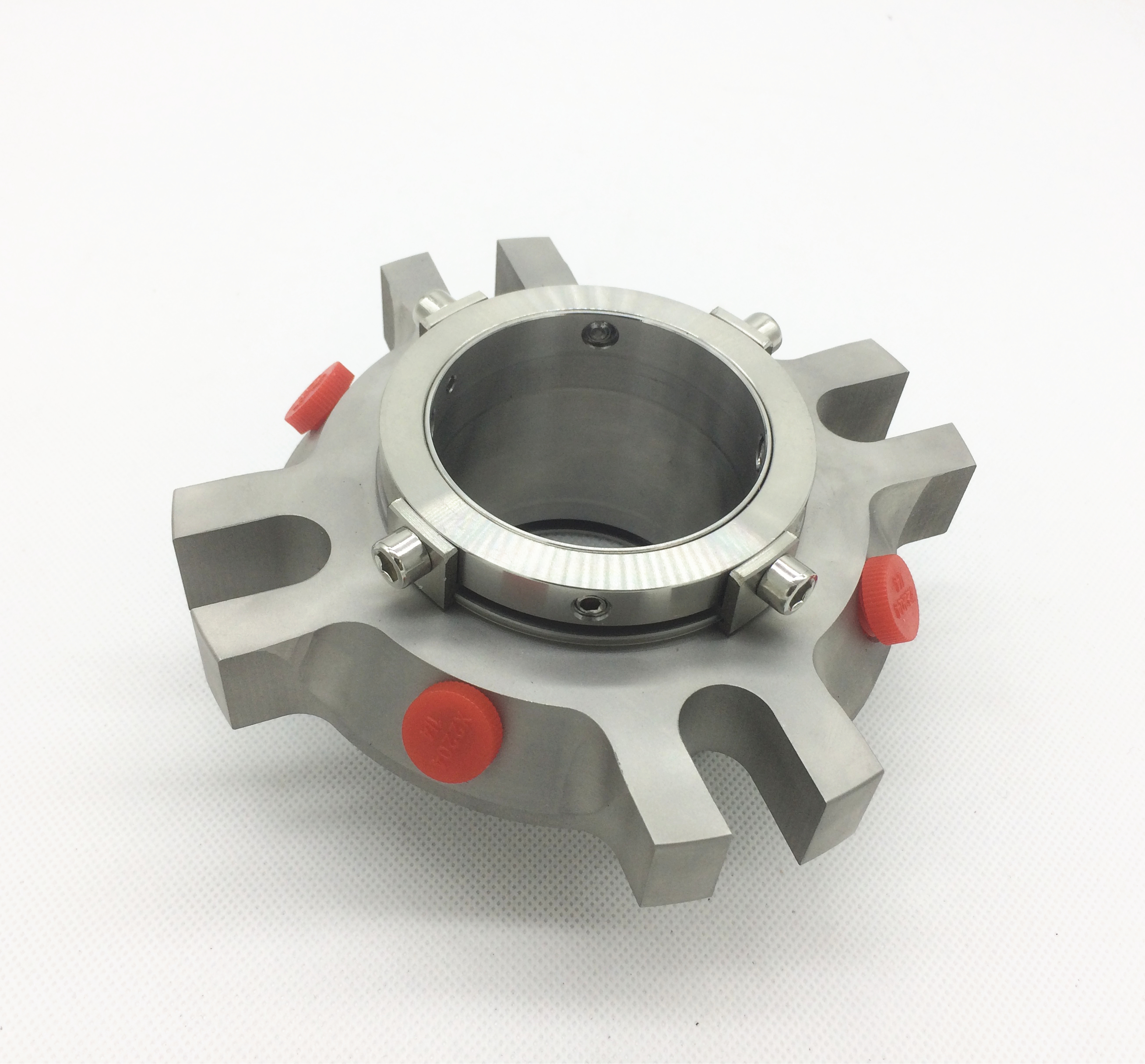

AES Seal offers single seals, double seals, bellows seals, split seals, mixer seals, and standard plus seals to improve how you handle your process. The most noteworthy of AES Seals product lines are the CSS and CSSN single seal cartridges. One of the most noteable features of the CSS seals are a metal to metal pin drive which eliminates potential impact damage. Instead of telling you about all of the types of seals I will limit our discussion to the main two that Processflo deal with. The two main types of seals that Processflo deals with from AES Seal are single and double seals.

AES Seal offer the following types of single seals to help improve your process: single mechanical seals, single cartridge seals, high performance mechanical seals, process protecting seals, single cartridge seals with axial movement, and a cartridge seal that replace packing. The following type of double seals are available: cartridge mounted mechanical seal, high performance mechanical seal, double monolithic stationary flow / convection, double mechanical seal (CDP, CDPN, CDFI, and CDFC), heavy duty double slurry seal, and double stationary seal with pumping scroll.

AESSEAL®, has grown to become one of the world’s leading mechanical seal manufacturers. With over 1,800 employees operating out of 230 locations in 104 countries, including 9 manufacturing and 44 repair locations, and has more than 300 customer service representatives who visit industrial plants every day.

AESSEAL® has annually invested over 7% of sales into R&D over several decades. Filing over 120 patents in the last 10 years, more than any other competitor, has seen AESSEAL® develop one of the most comprehensive standard inventory portfolio of mechanical seals, bearing protectors, seal support systems and packing. The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs.

This development is underpinned with a philosophy “to give customers such exceptional service that they need never seek another source of supply”. This philosophy is supported by the numerous supplier awards won by AESSEAL® and underlines that the commitment to service is more than just a statement.

AESSEAL® believe in operating in an ethical and sustainable manner, providing sealing solutions to customers that improve reliability and help reduce energy and water consumption. Their world class manufacturing facilities use the latest in machine tool technology and their systems and processes enable them be the world’s largest homogeneous mechanical seal manufacturer.

AESSEAL® has one of the most comprehensive component seal product portfolios available. With some 10,000 product lines available from stock, our inventory incorporates seals to suit an extensive range of pump types and applications.

Our unique, patented range of re-engineered component seals enables 44,000 permutations to be configured, allowing AESSEAL® to offer our customers the greatest possible product availability and service. AESSEAL® provides the sealing solutions you require – direct from one source.

Our component seals offer 100% compatible solutions with OEM parts and backwards compatibility ensures our products can be used with our customers’ existing stock holding. AESSEAL® component seals are designed with modularity at their core, allowing faster service whilst also incorporating design features which reduce the lifetime cost of the product.

AESSEAL Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs.Seacoast Supply maintains a large inventory of AESSEAL products.

Cartridge mechanical seal construction is a proven reliability improvement. The seals are pre-assembled at the factory, pressure tested and shipped as a unit, leading to improved performance as errors due to incorrect installation are reduced. Cartridge construction eliminates the need to measure and set spring compression, and having a mechanical seal pre-assembled means that the seal faces are protected from damage during installation.

A double or dual mechanical seal consists of two independent seals mounted within a seal chamber outside the pump, which is flushed with an independent supply. This makes them ideal for sealing hazardous liquids, liquids with abrasives or liquids that are corrosive, as the seal faces only see clean lubrication greatly increasing mechanical seal life.

AESSEAL® double mechanical seals have independent seal-face designs, to enhance safe containment of process fluid in the event of damage to any individual sealing element.

This means that no matter how well designed your mechanical seal or bearing systems are, without a reliable Seal Support System there is still the possibility of your mechanical seal failing. The innovative and reliable Seal Support System Range at AESSEAL® gives customers the confidence to remove this root cause of mechanical seal failure.

AESSEAL® offer a range of bearing protection devices suitable for most applications. The innovative LabTecta® and MagTecta™ products include patented features that deliver the best possible bearing housing sealing solution for your motor, pump, plummer block, gear boxes or steam turbine.

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

Micro Sealsis one of the leading specialists in the design and manufacture of Pump Mechanical seals, Seal support systems ,Sealing Components,and Rotary Unions/Rotary Joints for Pumps, Agitator, Reactors, Blowers, mixers, steam turbines and other rotary-motion equipment. For over 15 years we’ve been committed to designing and manufacturing sealing products and accessories of the highest quality. We leads the way in high-efficiency solutions using the latest technologies for maximum sealing performance.

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

When it comes to effective pump applications, working with the right seal manufacturer is essential. Ranked as the 4th largest supplier of mechanical seals globally, the AESSEAL® product line is specially crafted with a modular approach to fit a vast range of pumps and systems to prevent the release of liquids and gases.

Founded 1979, AESSEAL has grown over the past 43 years to become an industry-leading manufacturer of mechanical seals and support systems. Boasting a wide range of solutions from packing to dry gas compressor seals and a 97% on-time delivery rate, AESSEAL is trusted by operations the world over. AESSEAL maintains this high level of trust by meeting the highest standards of quality, constantly innovating their products, and always striving to achieve their core mission of making complex systems simple.

Developed in their state-of-the-art facilities and leveraging extensive research and development investments, AESSEAL’s mechanical seals are tested and optimized to deliver the highest level of performance. Using advanced manufacturing techniques, they produce seals with fewer parts that are more compact, robust, and reliable than competitors’ designs. AES also prioritizes modularity across products and models, enabling shorter lead times and greater customer value for money compared to competitors.

With an assortment of computational and numerical tools used in conjunction with their extensive testing program, AESSEAL designs products that keep your pumps and rotating equipment up and running better for longer.

AESSEAL manufactures a variety of seals and seal support systems for a wide range of pumps and rotating equipment used to support industrial and commercial applications around the world. With their complete sealing packages, they’re stocked and ready to outfit entire operations, including:

As a brand and company, AESSEAL prides itself on delivering quality, reliability, and great service, while operating in an ethical and sustainable way. Their sealing solutions will reduce your overall costs associated with energy and water consumption, as well as associated maintenance costs.

In addition to supplying the best equipment for your operations, AESSEAL also provides both onsite and remote maintenance and repair services. With certified engineers and reliability consultants in locations across more than 100 countries, they can work with clients to assess and improve their operations wherever possible.

Globally-recognised standards body, BSI, has published a case study of AES Engineering/AESSEAL’s journey to achieve Net Zero on all scopes. We are delighted that BSI shares our experience to encourage other businesses on their own Net Zero journeys.https://hubs.ly/Q01zrC2S0

If you are in need of an ASI©seal replacement, Gaddis Mechanical Seals is here to help. We offer replacement mechanical seals for a variety of applications, and our team is highly experienced in mechanical seal repair and installation. We understand the importance of keeping your machinery running smoothly, and we will work diligently to get your mechanical seals repaired or replaced as quickly as possible. With ASI© Mechanical Seals, you can rest assured that your mechanical seal repair needs will be handled promptly and professionally. Contact us today to learn more about our mechanical seal repair services.

Our Mechanical Seals are used in a wide range of pumps and rotating equipment worldwide to prevent liquids and gases escaping into the environment. We manufacture mechanical seal types to suit all industries and our investment in modular design means that we provide the best on-time delivery performance in the industry.

The AESSEAL® range of seals, seal support systems and bearing protectors are all designed to improve pump reliability and reduce maintenance costs. Our business is built around giving our customers such exceptional service that they need never consider alternative sources of supply.

AESSEAL®cartridge mechanical sealsare used in a wide variety of pumps and rotating equipment to prevent liquids and gases from escaping into the environment. Here are three benefits of AESSEAL®cartridge mechanical seals.

AESSEAL®cartridge mechanical sealsare pre-assembled at the factory, pressure tested, and shipped as a unit. This seal configuration eliminates the requirement for seal setting measurements at installation.

Spring tension is another crucial factor in a successful seal installation. Withcomponent seals, you must set the tension manually by adjusting the length of the installed seal spring. Withcartridge seals, the spring tension is preset, eliminating the time and potential errors of manual installation. A retaining device holds the rotating and stationary elements in correct alignment until the seal is mounted.

Cartridge seals are capable of handling the most demanding applications, including slurry applications and hazardous process fluid containment. AESSEAL®’s standardcartridge sealline includes the following.

For unusual applications, AESSEAL® also has a Standard Plus line that offers the same benefits as their standard seals while also meeting specific customer needs. This includes competitor replacement seals and seals designed for specific pumps and processes.

Cartridge mechanical sealscost more thancomponent seals. However,cartridge seals will save you money in the long run, thanks to lower maintenance costs. Potential savings come from reduced labor costs and less downtime when in-service seal replacement is required.

Are you interested in improving pump reliability, increasing uptime, and reducing maintenance costs? The experts at C&B Equipment can help you implement the bestAESSEAL®cartridge mechanical sealsand seal support systems for your application. We also offer a suite ofpreventative maintenance programs and repair servicesto ensure your equipment remains in top shape for the duration of its life!

8613371530291

8613371530291