high temperature mechanical seal pricelist

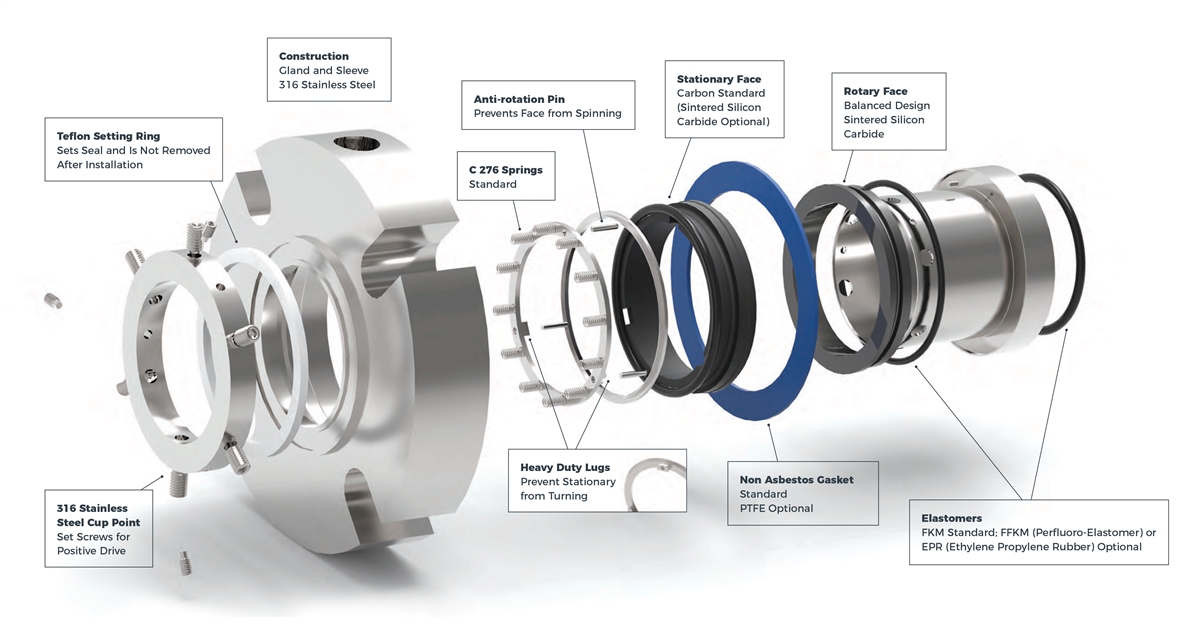

FSI Series 1015 mechanical cartridge seals are a premium grade product without the premium price. They"re ideal for use with most ANSI and DIN (standard and big bore) pumps and other types of pumps and rotating equipment. They have the following features:

Many tools can seal used when installing mechanical sealals that are not readily available, Alibaba.com offers a variety of mechanical seal tools that can seal used when installing mechanical sealals. This seal is not only for mechanic, but they are also in need of this material.

The many benefits of mechanical seals are that they offer, as they are less resistant to wear and tear on all occasions. Mechanical seals are the most durable, and seal option for those that require a lot of water and air at the same time.

Hydraulic seals are ideal for those that require higher pressure to maintain. On the other hand, the plunging seal is a common choice of mechanical seals, such as those with OKO"s, they all use the same functions of water and gas.

Usage/Application: Thermic Fluid, Fatty Acid, High Temperature, Hydrocarbons, Petroleum Refineries, Edible Oil Refineryread more... Brochure

These seals are designed to face higher temperature. That is possible by using teflon wedge as secondary elastomer. small springs(Multi springs) situated at peripheral of the seal it is dynamically balanced too. So we can go for maximum of 6000rpm by these seals

We bring forth our clients an advanced gamut of Teflon Bellow Seals. These seals are externally mounted and have low pressure. Moreover, these seals are independentread more... Brochure

• Drive mechanisms external to the product;• Seal faces positioned for maximum protection;• A dynamic elastomer moves on a non-metallic surface, eliminating fretting defects;• Hydraulically balanced;• Cartridge easy to ...

• Static grafoil gaskets;• Temperatures up to 425 ºC;• Inconel bellows available;• Cartridge easy to install;• Metal bellows provide better faces alignment;• Does not have dynamic gaskets;• Self-cleaning;• Adapts to API ...

The MTM10-11 is a conical spring mechanical seal developed by Microtem. It is mainly used for general services machinery at low and medium pressure. This unbalanced mechanical seal ...

Single mechanical seal, balanced, independent of the direction of rotation with multi-spring configuration. The MTM180 Series represents the mechanical seal with the ...

... the Type 1 elastomer bellows seal is widely recognized as the industry"s workhorse. Suitable for a wide range of service conditions ranging from water and steam to chemicals and corrosive materials, the Type 1 mechanical ...

Our Mechanical seal model CR is widely used for GRUNDFOS-PUMP . The normal material combination include SIC/SIC/viton/machined ss304,TC/TC/VITON/machined ss304 and SIC/ SIC/VITON/SS304. ...

... . The sleeve is fabricated from a new grade of carbon fiber reinforced PTFE providing superior chemical resistance of PTFE and consistent mechanical properties. A carbon fiber PTFE ...

The M7N series is made of compact structure. It has a various application scope and high interchangeability. This series is widely used in petrochemical pumps. It is also embedded with drive collar that is clamped by the drive lug, in ...

The PTFE bellows type mechanical seal, manufactured by Chinabase Machinery, can operate on a temperature range of -45°C up to 250°C on a pressure ≤1.2 Mpa and speed of ≤15 m/s. The stationary ...

The SAF is a double-acting seal particularly engineered to suit pumps, screens, knotters, sorters and pulpers in heavy process industries where liquids containing solid particles and impurities are involved. Seal ...

The 3-D Seal is designed to be the foremost solution for high radial misalignment and high run out applications. By combining Garlock’s proven P/S®-II and expansion joint technologies into ...

Bellow mechanical seal made of PTFE. Commonly used forstrong corrosive fluids.• Unbalanced Mechanical Seal.• Independent of direction of rotation.• External assembly

... 10T TS 10R Our Mechanical seal model TS10T TS10R can replace John Crane 10R 10T. 10T is integral rotary face ,10R is insert rotary face Operating Limits Pressure: 1.3MPa Speed: 15m/s Temperature: -...

We manufacture face seals for hydraulic and pneumatic applications in the following designs:- rod seals and piston seals - single-acting - double-acting - rotatory seals ...

Robco"s Mechanical Seal Division manufactures, distributes and customizes mechanical seals, as well as being a repair facility for virtually any mechanical seal brand, utilizing the latest technology and state-of-the-art manufacturing equipment. Robco’s seal designs are customer driven to provide the best possible solutions to sealing problems.

Robco will repair: Borg-Warner, Chesterton, John Crane, Durametallic, EG&G, Flex-A-seal, Flexibox, Flowserve, Garlock, Pac-Seal, U.S. Seal, and virtually any other brand.

Mechanical seals are used everywhere liquids and gases are transferred through rotating equipment. Robco’s seals and packing are the first step to efficiently control leakage and reduce operation costs.

The ideal seal for alumina applications, specifically designed to operate in this challenging environment, the Robco DRYTEK seal will provide maintenance-free operation at least five to twenty times longer than your average alumina screw conveyor seal.

•Better abrasion resistance •Dry-seal, no lubricant required •Sealing components rotate with the shaft, maintaining an airtight seal •Adapts to axial and radial movements of the shaft •Available in C.E.M.A. and METRIC standard shaft sizes.

Double balanced cartridge seal for pumps, agitators and mixers that prevents the leakage of toxic, hazardous, corrosive and costly fluids to the atmosphere.

Robco uses specialized equipment to ensure that rebuilt seals operate equal to brand new, with mechanical seal manufacturing and rebuilding experience dating back to 1978, servicing petrochemical, pulp & paper, steel, mining, waste water, utilities, boilers and more...

We rebuild all major brands at competitive prices with premium quality parts that meet all OEM specifications. We offer a free estimate and failure analysis. Rebuild outlay normally varies from a third to half the cost of a new seal, so lower your inventory value and reduce your overall operations cost.

By centralizing your repairs: Robco rebuilds all major brands in one location, simply complete our Seal Repair Form to be enclosed along with your seal shipment and we’ll take care of the rest, returning your seal looking and working like new. Robco tags all rebuilt seals for future rebuild identification, tracking seal life and failure patterns.

Mechanical seals are indispensable for sealing rotating shafts. They make sure that the fluid handled remains in the system, prevent emissions and thus protect the environment from contamination. High-quality shaft seals in the form of mechanical seals also ensure maximum economic efficiency and operating reliability for pumps. This is crucial because the majority of repairs arise due to sealing problems.

And this is where KSB’s mechanical seals can make a difference: as well as impressing with a robust design, they offer straightforward installation and optimal integration in the seal chamber – ensuring reliable and efficient system operation.

Having a definite quality administration system, we are providing a comprehensive assortment of Mechanical Seal to our customers. Valued for their perfect finish, sturdy built and longer life; these are hugely commended. Along with this, the offered product is designed by hard-working engineers, who ensure to comply it with the industry laid standards and norms. The offered product is extremely praised by our clients all over the country. Also the customers can avail these at affordable rates from us within the assured time.

Mechanical shaft seals are the best way to seal a pump. Face seals prevent leakage better than packing and if selected properly will last longer. Mechanical seals used in clean well lubricated applications can last 20 years. Seals can be constructed in single or double configurations, allowing only a vapor to escape.

Shaft seals are engineered forshaft-sealingapplications to serve Original Equipment Manufacturers or field replacement requirements, our seals will hold up to difficult applications. We can also asset in theconversion from braided pump packing to a mechanical seal.

American Seal and Packing delivers a full range of rotary mechanical seals configurations and component materials - to handle pump service requirements in a wide range of industries. . When you Specify a AS&P seals you have the advantage of proven reliability. When we need engineered seals for difficult applications we utilize the engineering departments of some of the top mechanical seal manufacturersin the world.

Many factors come into play when a mechanical seal is installed onto a rotating shaft. A major consideration is the equipment condition, which includes the amount of shaft movement when rotating and/or condition of the stuffing box face. Mechanical seals are designed with assumptions regarding the amount of motion the devices can be expected to withstand and still provide no visible leakage during operation.

A.W. Chesterton® is a manufacturer of industrial fluid sealing and maintenance products including hydraulic seals, pneumatic seals, mechanical seals and packing, oil seals, o-ring seals, metric seals, lip seals and many other products. We are ISO 9001/14001 and MRP II Class A certified.

AccroSeal® is committed to manufacturing high quality seals to your design at competitive prices. The AccroSeal® technical sales team works directly with your engineering department to solve the most difficult sealing applications. Our sealing product portfolio includes wipers, lip seals, o-rings, piston rings, v-rings, and more produced from our exclusive Accrolon® engineered compounds.

American High Performance Seals Inc. designs and manufactures hydraulic seals, rotary shaft seals, oil seals, gaskets and other high performance rubber and plastic parts. AHP Seals designs and manufactures the most durable seals available and delivers them within 1-4 days.

Since 1981, American Seal Supply Co. has been distributing top-quality fluid seals and packing to its varied customer base. Among our product offerings are oil seals, rubber seals, o-ring seals, metric seals, Teflon® seals and lip seals. We also supply hard-to-find and custom-made seals.

American Seal & Packing is a leading manufacturer & distributor of mechanical seals, Grafoil, gasket material, cut gaskets and quality o-rings. We are constantly working to provide innovative solutions to mechanical seal problems. With our wide selection of products we"re finding better ways to serve our customers all the time. Contact our expert staff for a quote to meet your needs.

Appleton Packing and Gasket was born out of the need for better service. Among the many products we offer are mechanical seals, oil seals, gaskets, mechanical packings and o-rings. We attribute our success to the trust placed in us by our customers. Our continuing goal is to offer outstanding quality products at competitive pricing, in a manner which will best satisfy customer needs.

Beacon Gasket & Seals Co. is fully tooled to cut your requirements from compressed non-asbestos, gylon, gore-tex, flexible graphite, teflon, silicone, red rubber and neoprene rotary seals and other hydraulic sealing systems. Specializing in MTBF Solutions and representing the best manufacturers in the industry, we are excited about our expanding product offerings and the opportunity to serve you.

CoorsTek provides custom engineering, materials expertise, operational excellence and rapid execution to make our world measurably better! Technical ceramic, engineering plastic and specialized metal components help us build tomorrow’s technology. CoorsTek hydraulic seals offer extreme-temperature, high-pressure, chemically inert, static and dynamic seals for the most demanding applications.

CW Marsh offers you the best of both worlds: the toughest, most versatile natural material available for sealings and the benefits of a century of technological advancements and product innovation. CW Marsh produces leather vee packings, cups, u-packings, flanges, and back-up washers, all manufactured and backed with the same old-world dedication to quality, service and dependability.

At D&D Engineered Products Inc. we manufacture top of the line hydraulic seals, gaskets, various o-rings, high temperature tapes, compression packings, and much more. We promise to cater our product to any needs you may have, such to ensure your satisfaction. If you would like more information please give us a call.

East Texas Seals, Inc. is a distributor of O"Rings and Gaskets for Parker Seal. If you need an O"Ring, Seal or Gasket, we can fulfill your needs. We have supplied the Oil Field industry with O"Rings to adequately keep their oil rigs up and running. East Texas Seals, Inc. works closely with the U.S. Government and Defense departments, shipping and storage companies and all commercial sectors.

EPM, Inc. is your one stop shop for seals, with billions of styles including rod seals, piston seals, symmetrical seals, V-Rings, wipers, rotary shaft seals, wear rings, static seals, back-up rings, o-rings, buffer rings, u-cups, oil & grease seals, cast iron piston rings and gaskets. Whether you need one or one million, EPM offers fast turnaround and great prices on seals up to 21inches or 600mm.

With an extensive customer service center for catering to customer needs, Freudenberg-NOK manufactures a number of different seals. These offerings include hydraulic seals, pneumatic seals, o-ring seals, rod seals, piston seals and pump seals.

Garlock Sealing Technologies is the global leader in high-performance fluid sealing products for the world’s processing industries. Their 12 manufacturing facilities in the U.S., Canada, Europe, Asia and Latin America collectively produce the broadest range of fluid sealing products designed specifically for industrial applications. Some products include metal gaskets, o-rings and oil seals.

Here at Gasket & Seal Fabricators, we supply die cut, lathe cut, extruded, molded and spliced gaskets of all types, sizes and shapes. We specialize in both commercial and military spec materials, including many UL, FDA and NSF recognized materials. Our in-house capabilities include various types of die cutting equipment such as punch presses, both manual and automatic roll feed, clicker presses, and beam presses. Contact us for more information!

We manufacturer high quality hydraulic seals that are ideal for a wide range of industries. Here at Global O-Ring and Seal, LLC we are a trustworthy manufacturer who is known for our ability to adhere to all of your special requests. These seals come in a number of different materials including Buna, Viton, Silicone, Teflon, Aflas and more. Please give us a call today to learn more!

We are a preferred supplier to most of the leading global manufacturers of hydraulic equipment, air compressors, transmissions, hydraulic clutches, valves and shock absorbers. We manufacture hydraulic seals and pneumatic seals among other products. Let us work together to enhance your applications.

Over 100 years, Hallite Seals International has been at the cutting edge of fluid power technology, manufacturing a wide range of rod / gland, piston, and static seals, as well as support and bearing components, for technically challenging applications, from a wide range of materials which include Polytetrafluoroethylene (PTFE), Polyurethane (AU), nitrile rubbers (NBR) and Fluoro-elastomers (FKM).

For over 34 years, Harwal has continued to be the leader in metric oil seals. With one of the largest seal selections, 1,000,000 seals in 7,000 different sizes in stock, be assured we"ve got what you need. We also offer V-rings, standard inch sizes, end caps, Teflon® seals, wipers and gamma seals!

For over 34 years, Harwal has continued to be the leader in metric oil seals. With one of the largest seal selections, 1,000,000 seals in 7,000 different sizes in stock, be assured we"ve got what you need. We also offer V-rings, standard inch sizes, end caps, Teflon® seals, wipers and gamma seals!

Hi-Tech Seals is capable of either creating parts with our in-house machining department or utilizing our relationships with industry leading seal manufactures. Our sales staff works with customers to find the best solution to replicate existing or design new parts. Different manufacturing options include machining, molding and extrusion.

At HydraPak, we make replacing your hydraulic seals easy, so you can get your seal repair jobs completed quickly, saving you time money. Even the most difficult seal repair challenges can be handled by our knowledgeable staff to get your equipment. We offer expertise in products for high-tech applications, as well as the ability to source everything from o-rings to sheet goods to sealing devices.

Being a seal manufacturer and distributor, JEM Seal Co. offers mechanical seals, hydraulic seals, oil seals, rubber seals, and more. Our mining equipment industry seals are used exclusively by Hallite Mining. Our stock of piston seals, rod seals, and wipers are in stock for your specific needs.

Encapsulated O-ring manufacturer and Precision extruder M-Cor Inc. is a leading U.S. producer of high performance sealing products for extreme environments. Extruded profiles are converted into o-rings, Teflon® encapsulated o-rings, camlock gaskets, chemical transport tubing and other sealing products. With in house tooling capabilities, we are able to immediately respond to customer requests.

Martin Fluid Power distributes on a worldwide basis, hydraulic seal repair kits, o-ring seal repair kits, metric seals, Teflon® seals and a lot of other types of seals, plus gaskets and packing. Our products come in many different shapes, sizes, materials and colors to suit your specifications.

Speed is of the essence at Michael-Stephens Co. Within 24 hours of your request, we can customize nitrile oil seals for you in a variety of profiles and materials. We work with a wide range of Teflon®-filled items. We also supply hydraulic seal kits; our website lists the wide range of manufacturers we carry.

Pacific International Bearing is capable of providing solutions for all types of applications with an educated and committed staff here to service your needs. PIB offers quality seals from Chu Hung Oil Seals Industrial Company (manufactured in Taiwan). They hold ISO 9001 Quality Certificates to provide top quality oil seals. Seals come in a variety of sizes and lip designs to suit your need.

With over 175 years of accumulative sealing experience, this team has helped pioneer the development of high performance seals around the world. Our core people excel at innovative seal design, high performance materials utilization, and efficient production techniques with a Certified ISO 9001: 2000 and AS9100 Rev. Some products of ours include, rotary shaft, rod and piston seals.

We are not only technically knowledgeable about hydraulic seals, but we also have the hands-on experience to back it up. We have over 30 years of industry experience, and we can use that experience to benefit you. We have faced nearly every problem and know the right solution for most problems. We can offer both stock and custom seals to benefit you. We will always put the customer first, so contact us today!

R&B Plastics is a supplier of custom machining serving a variety of industries including electronic connectors, plastics, filters, bearings, hydraulics and valve seals. With 34 years experience, R&B Plastics provides quality products to both the U.S. Government and major aerospace companies such as Boeing Corporation.

R.T. Dygert International is one of the largest distributors located in Minneapolis, MN and an office/warehouse in Niles, IL. RT/Dygert International prides itself on its responsive, service-driven culture and its reputation for its core values of quality, honesty and integrity and committed to a process of continuous improvement. Some of the products include piston and rod seals and o-rings.

Seal Master® specializes in manufacturing custom-built inflatable seals. These products include metric seals and rubber seals available in different sizes and shapes. Our seals are used in a wide variety of applications, including valves, robotics, conveyors, gates, brake devices and actuating devices.

Established in 1979, Southwest Seal and Supply has grown to become one of the most predominant distributors of sealing, hydraulic hoses, fittings, couplings/connectors, gasketing and fluid control products in the Southwest. We offer a wide range of products including the best in selection, quality, and value-added services.

System Seals offers a complete range of industrial hydraulic seals: small or large diameter, low or high pressure, reciprocating or rotary motion, dynamic or static sealing. We carry in-stock standard sizes plus are flexible enough to cater to all sizes. Rod Seals, Piston Seals, wipers & guide elements.

The T-Bird Group is a collection of distributors and manufacturers of seals, bearings, v-packings, unified pistons, wear rings, wipers, wear strips, u-cups, and machined plastic components.

Texacone Company, Inc is a manufacturer of fabric-reinforced elastomer and urethane molded products. Texacone specializes in molded seals up to 65" diameter in solid or split from a wide variety of fabric-reinforced elastomers. High temperature materials also available. Some of our products are: v-rings, flared u cup, piston cups and flanges.

Pumping of low-temperature and cryogenic fluids requires specific and unique engineering technologies for the shaft sealing system. When correctly applied, these technologies provide the containment and reliability to meet pumping equipment operators’ requirements.

Due to their extreme sub-zero temperatures, low-temperature hydrocarbons and liquefied atmospheric gases pose significant challenges to pumping, and particularly to the specification of their shaft sealing systems. To provide long-term reliability while ensuring that these pumped fluids are safely contained, the designs of the shaft seals used in cold-fluids pumps are often highly specialized.

For example, low temperatures have significant implications for the choice of materials used in the seal construction. Metals become increasingly brittle as the temperature is reduced; therefore, thermal constriction and expansion must be factored. The volatility and flammability of low-temperature hydrocarbons pose special challenges for the design of pump shaft seals, as well as for the release of hazardous emissions to the atmosphere. Liquefied oxygen, with temperatures much colder than these hydrocarbons, is a strong oxidizer and can cause certain materials to spontaneously combust.

Low-temperature hydrocarbons are typically pumped at sub-cryogenic temperatures, between –20°C and –140°C (–5°F to –220°F), although lower temperatures are occasionally encountered. They have high vapor pressures at ambient temperatures and are pumped at low temperatures to reduce the pumping pressures. These hydrocarbon fluids include ethylene, LNG, LPG, methane, butane and propylene.

Liquefied atmospheric gases include oxygen, nitrogen, argon and the noble gases. They are typically pumped at cryogenic temperatures ranging from –175°C to –198°C (–285°F to –325°F). Impeller inducers are often used, as they are frequently pumped with a low vapor pressure margin at the pump suction.

Low-temperature hydrocarbons are commonly pumped with API 610 (VS6) vertical multistage double-casing pumps that feature a warming chamber, known as a cofferdam (Fig. 1), which thermally isolates the shaft seal from the cold pumped fluid. Cofferdams enable a greater range of shaft sealing solutions to be used on these pumps, utilizing traditional sealing technology.

A cofferdam is a chamber between the pump discharge and the mechanical seal that is connected to the pump suction, or the vessel from which the pump is drawing suction. Ambient heat surrounding the pump, together with energy from the shaft and bearings, causes the liquid in this chamber to vaporize into a gas, which forms an insulating barrier between the seal and the process fluid. Cofferdams can be incorporated only into vertical pump designs.

Although vertical arrangements are common, various horizontal pumps can also be used. In these types of pumps, the shaft seal is in direct contact with the cold-pumped fluid; therefore, selection of the seal materials for low-temperature operation becomes more critical.

Similar to pumping equipment for low-temperature hydrocarbons, pumps used for liquefied atmospheric gases have a combination of vertical multistage pumps, together with horizontal single-stage pumps. These systems generally do not follow API pump design standards.

However, as the temperatures of liquefied atmospheric gases are much colder than those at which hydrocarbons are pumped, cofferdams cannot be used on these pumps. Although a mixture of vertical and horizontal pumps is commonly used at air liquefaction plants, mobile trailer truck unloading pumps are almost exclusively overhung single-stage pumps, either with direct-drive or speed-increasing gearboxes.

For pump designs where the mechanical seal is immersed in the pumped fluid, the vapor pressure margin in the seal chamber becomes critical. Where the vapor pressure margin is low, the heat energy from the mechanical seal faces can vaporize the fluid around the seal and in the seal interface, resulting in dry running of the seal. In this situation, a dual-pressurized seal is required. A dual-pressurized seal provides a stable barrier fluid to lubricate the seal faces, thereby negating the effect of vaporization of the pumped liquid at the seal faces.

API Plan 53B and 53C barrier systems are commonly selected for dual-pressurized seals to provide a source of warm, clean and stable barrier fluid to the mechanical seal. When an API Plan 53C system is selected, extra care should be taken to ensure that the pressure-amplifying piston and rod seals are insulated from exposure to cold temperatures.

The availability of suitable barrier fluids becomes limited at low temperatures, as the viscosity of many fluids becomes too high at the seal chamber operating temperatures. Mono- and di-ethylene glycol mixtures with water can be used down to temperatures of –29°C (–20°F). Alcohols, such as propanol (propyl alcohol), are suitable for even colder temperatures reaching –70°C (–95°F). Synthetic oils can also be used; however, careful consideration to their pour point is required, and a heating system may be needed to warm the barrier fluid to maintain a suitable viscosity.

When sufficient vapor pressure margin exists within the seal chamber, a dual-unpressurized seal can be selected. Typically, these designs feature a dry-sliding containment seal fitted with API Plan 76, or a combination Plan 72 and 76. These seal arrangements have the advantage of removing the low-temperature limitation of barrier fluid selection.

Pump designs utilizing a cofferdam require a dual-pressurized mechanical seal, as the seal chamber contains no liquid to lubricate the mechanical seal faces.

Icing, due to condensation of atmospheric humidity, can create a problem for sealing systems handling cold hydrocarbons. Since condensing water expands as it freezes, it can interfere with the operation of the mechanical seal if it reaches the seal’s operating mechanism. Extra protection should be applied to equipment exposed to atmospheric elements, such as rain. An API Plan 62 using a dry nitrogen quench can displace atmospheric humidity, thereby protecting the mechanical seal from these effects.

In applications handling liquefied atmospheric gases, pump seal reliability takes precedence when selecting a shaft sealing system. Unlike hydrocarbons, emissions of gases to the environment by liquefied atmospheric gases pose relatively minor hazards and, therefore, are not as critical a factor as seal reliability.

Two commonly employed shaft sealing technologies are used in pumps handling liquefied atmospheric gases: single mechanical seals and segmented bushings.

Single mechanical seals.The most common solution for pumps used in air liquefaction plants and mobile-transportation unloading pumps is the single mechanical seal. The major difference between the two is that the mobile unloading pumps tend to be smaller and often use non-cartridge seals. Cartridge seals are commonly found in larger machinery at air liquefaction plants. Single mechanical seals fall into two sub-categories: contacting wet seals and vaporizing liquid gas seals.

Contacting wet seals utilize a metal bellows to provide elastomer free-axial flexibility. Seal face materials typically include filled tetrafluoroethylene running against a tungsten carbide or hard-coated, stainless steel mating ring.

Vaporizing liquid gas seals (Fig. 2 and Fig. 3), similar in construction to contacting wet seals, feature engineered seal-face topography that allows the controlled vaporization of the pumped atmospheric gas to produce a highly reliable seal that exhibits controlled, low-level leakage rates.

Segmented bushings.A segmented bushings sealing configuration is often found in vertical multi-stage pumps at air liquefaction plants. The design provides a controlled leakage by breaking down the sealed pressure over a series of tightly controlled bushing clearances. Leakage rates are higher than those of mechanical seals; however, these leakage rates are often considered acceptable by this industry.

As mentioned, low temperatures have significant implications for the choice of materials used in the seal construction. This is especially true for elastomers applied in seals for pumps handling low-temperature hydrocarbons. Depending on the material grade used, elastomers have a variety of minimum temperature limits, but none can survive dynamic operation at true cryogenic temperatures.

Engineered polymer seals are an option at temperatures below the limits of elastomers; however, many of these designs will not function with pressure reversals applied to the sealing ring, which may be required in the mechanical seal design when support system failures occur.

Elastomers can survive at significantly lower temperatures below their operational limits when the seals are not in operation (i.e., static); however, they must be warmed up prior to operation. Commissioning of shaft seals containing elastomers must be completed carefully to ensure that equipment is at the correct temperatures before startup. Blowdown—the rapid depressurization of a vessel/pipeline—is one situation that can create excessively low temperatures for mechanical seal elastomers.

Thermal expansion and contraction are also considerations. The cavities in which elastomers or engineered polymer seals are installed will change with decreasing temperatures, as well as the dimensions of sealing elements installed in these cavities. Additionally, clearances between dissimilar materials, such as bushings, will require review. Mechanical seal manufacturers take these factors into consideration during the design of the mechanical seal for these cold services.

Since metals become increasingly brittle as the temperature is reduced, as a general rule of thumb, martensitic and ferritic stainless steels should be avoided in preference to austenitic stainless steels.

Since pumping equipment is often used interchangeably between different atmospheric gases, sealing of liquefied atmospheric gases presents some unique challenges to the selection of materials.

Liquefied oxygen is a strong oxidizer and can cause certain materials to spontaneously combust. Additionally, any organic contaminates on the seal can lead to spontaneous combustion, including metal cutting fluids, fibers from cleaning rags, and even oils from human fingerprints. To meet oxygen service requirements on seals, stringent cleaning specifications must be employed to ensure that the seal is free of any contaminates that may create a fire hazard while in service. Additionally, the materials of construction must include materials that are compatible for use in oxygen service.

Aluminum alloys should be avoided, as they can become hazardous when their protective oxide film is stripped from the material, such as when abrasion occurs. Lubricants used in the assembly and operation of the mechanical seal must be free of hydrocarbons and compatible for use in oxygen service. Packaging of the seal should also be suitable to preserve the cleanliness of the seal prior to installation into the pumping equipment, which must be performed in a suitably clean environment.

Of the many pump mechanical seal applications in use throughout various industries, those that deal with low-temperature and cryogenic processes rank among the more challenging.

It is critical to keep these seals, which handle low-temperature hydrocarbons and liquefied atmospheric gases, in optimal operating condition to ensure that the pumped fluids are safely contained, while providing long-term reliability. HP

Mark Savage is a Product Group Manager at John Crane, responsible for the application, design and development of metal bellows seals for pumps, compressors and rotating machinery. He has worked in the sealing industry for 25 yr and has been involved with the development of best practices for shaft seals and their support systems. Mr. Savage holds a BE degree in mechanical engineering from the University of Sydney, Australia. He is a member of the Fluid Sealing Association and Vice Chair of the Association’s Mechanical Seal Division, Chair of the Mechanical Seal Technical Committee and Vice Chair of the Government Relations Committee. He is also a member of NACE International and the Society of Tribologists and Lubrication Engineers (STLE). Mr. Savage has authored several publications on mechanical seals and support systems and their application to minimize environmental impact.

8613371530291

8613371530291