type 1 mechanical seal supplier

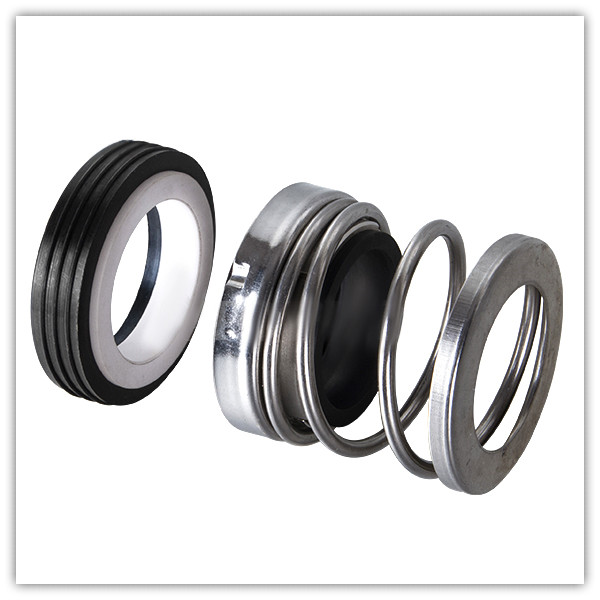

With its proven track record of exceptional performance, the Type 1 elastomer bellows seal is widely recognized as the industry"s workhorse. Suitable for a wide range of service conditions ranging from water and steam to chemicals and corrosive materials, the Type 1 mechanical seal is ideal for use in pumps, mixers, blenders, agitators, air compressors, blowers, fans and other rotary shaft equipment.

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

We recognize and understand the vital role of john crane type 1 mechanical seal in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale john crane type 1 mechanical seal in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider john crane type 1 mechanical seal requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

A Bellows seal does not have a secondary seal that must move along the shaft or sleeve to maintain seal face contact. The secondary seal is static state at all times, even when the pump is in operation.

Primary seal face wear is typically accommodated by welded metal or elastomeric bellows which move to assist in the compression of the rotary to stationary seal faces.

Bellows seals allow for high and low temperature applications when used in conjunction with metal bellows. They do not require a rotating secondary seal, which means it is not prone to secondary seal hang-up or fretting along the shaft or sleeve.

Type-16 is a mechanical elastomeric bellows. Seals for inch shafts. Application: Pumps for swimming pools. Analog mechanical seals: Flowserve 16, SEALOL 6, US SEAL A, John Crane 6, Burgmann BT-PNT, Vulcan 60/65, Sterling 216/217, Roten 16, AESSEAL B04 / B04U. Mechanical seal for Wilo pump, K, KM, X, AH, AHP, AH, Calpeda, DAB, Ebara, Grundfos, pump KSB, Allweiler, SALMSON, ACD Cryo, Flygt, IMP Pumps, LOWARA, PENTAX, Foras, Fristam, pump SPERONI, ZENIT, Inoxpa, JL, Johnson pump, KOLMEKS, Pedrollo, SAER, Vulcan, WQ, WQK, pump Tuchenhagen, ALFA LAVAL, Donjoy, Mission Magnum.

Aesseal B04, Aesseal B04U, Burgmann BT-PNT, Flowserve 16, John Crane 6, LIDERING LRB02, PacType 16, Roten 16, SEALOL 6, Sterling 216, Sterling 217, US SEAL A, Vulcan 60, Vulcan 65

* The John Crane and Flexibox trademarks are trademarks of their respective owners, and neither entity is affiliated with NE Seal Ind. Prod. LTD, its products, or its website, and does not manufacture, sponsor, or endorse its products.

Hayes Pump distributes the vast selection of John Crane mechanical seals. The range of seals available includes high performance, low emission petroleum seals, vessel and agitator seals, heavy-duty slurry seals and a variety of elastomer, formed and metal bellows seals suited to numerous applications. Hayes Pump is a factory-trained, stocking distributor for John Crane and provides local support and inventory.

John Crane has a strong legacy that dates back to the creation of the Crane Packing Company in 1917. Innovators from the start, John Crane designed the world’s first automotive mechanical seal in 1949. The groundbreaking design was soon followed by the development and introduction of the John Crane Type 1, end-face, elastomer bellows shaft seal. This patented product revolutionized sealing technology and is still one of the most widely used seals in the industry. Today, they are part of Smiths Group.

Hayes Pump carries the widest selection of seals in the market. We have the right solution for virtually any application. We will deliver unequaled performance, reduced installation times and lower maintenance costs. Rapid shipments are available from our stocked warehouse.

Dry Gas Mechanical Seals are non-contacting, dry-running mechanical seals and are designed to not contaminate a process. These seals are optimal for harsh working environment such as oil exploration, extraction and refining, petrochemical industries, gas transmission and chemical processing.

Metal Bellows Mechanical Seals allow for higher flow rates and less clogging than traditional spring seals. Bellows technology creates a uniform outside wall for uniform movement under hydraulic pressure. These seals are known for their reliability, tight tolerances, and compatibility with harsh media in pump systems.

PTFE Bellows Mechanical Seals are engineered for maximum reliability in extremely corrosive applications such as high concentrations of acids, salts, strong oxidizing and reducing agents and chemically active organic compounds.

Split Mechanical Seals use the latest modular split seal technology from John Crane. This combines the unique design requirements for wet-running and dry-running services onto one common seal platform.

Elastomer Bellows Mechanical Seals are widely recognized as the industry’s workhorse and suitable for a wide range of service conditions ranging from water and steam to chemicals and corrosive materials.

PTFE Wedge Mechanical Seals are used on corrosive applications, typically for chemical or hydrocarbon processing. Choices range from graphite-based wedges for corrosion resistance or high-temperature applications to DIN seals for general, low, medium and high pressure duties. Alternative seat designs options are available to suit product and operating conditions of applications.

Vessel and Agitator Mechanical Seals range from single Dry-running Mixer and Agitator Seals suitable for explosive atmospheres to Modular, high-performance, Agitator seals for glass-lined vessels. John Crane’s DIN vessel seal family has been specifically designed to suit all DIN vessel and agitator applications for the chemical and pharmaceutical industries.

Labyrinth Mechanical Seals are known for their long life and lack of friction to help prevent leakage. Many gas turbine engines, having high rotational speeds, and pistons use them to store oil and seal against high pressure.

O-Ring Pusher Mechanical Seals range from single cartridge pusher seals designed to help prevent emissions leakage in most refinery applications. Additional high-performance, low-emission cartridge seals designed to provide additional safety for hazardous to the Type 8B1 design which has been the preferred choice for safe, reliable, un-pressurized tandem and pressurized dual seal arrangements in petroleum services for more than four decades.

Slurry Mechanical Seals are designed to operate in the harshest abrasive slurry environments. These seals have unique design features allowing seal to operate without a flush, reducing total cost of ownership.

8613371530291

8613371530291