api 610 mechanical seal code manufacturer

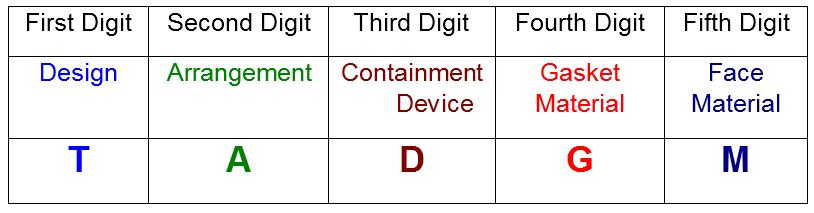

A seal code is an abbreviated method of communicating basic specifications for the mechanical seal. Sadly, the seal code has been changed with every edition of API 682. Fortunately, the new code, described in API 682 4th Edition Annex D, is the best to date and includes some concepts and codes from the historical API 610 seal code. The new code uses eight fields:

API 682 4th Edition was the first edition to include materials in the description and in many ways represents a combination of API 682 coding and the old API 610 codes.

4th Edition coding comprises four sections, some being sub-divided. The table below shows the construction of a typical seal code, it is intended to accurately describe the seal and seal system being implemented in a given application.

T: Seal type A, B or C per API 682 4th Edition definitions. For dual seals using different inner and outer seal types, show both types using the format inner/outer.

Note that the codes used for Design Options are the same as those used in API 610 for materials that are included in both systems. On the other hand, some materials cannot be specified because API 682 does not recommend them. Such materials must be specified with an “X”.

For many years the pump standard API 610 contained a mechanical seal coding system which became widely used in industry. This coding method provided a reference to the nomenclature and features used with mechanical seals that were current during that time period. While this coding method is obsolete it still is still being used in some areas of industry. It is presented herein as a historical reference only.

A very commonly used code was BSTFM which translates to a balanced single seal with throttle bushing in the gland plate. Gaskets would be FKM (fluoroelastomer). Seal faces would be carbon vs nickel bound tungsten carbide.

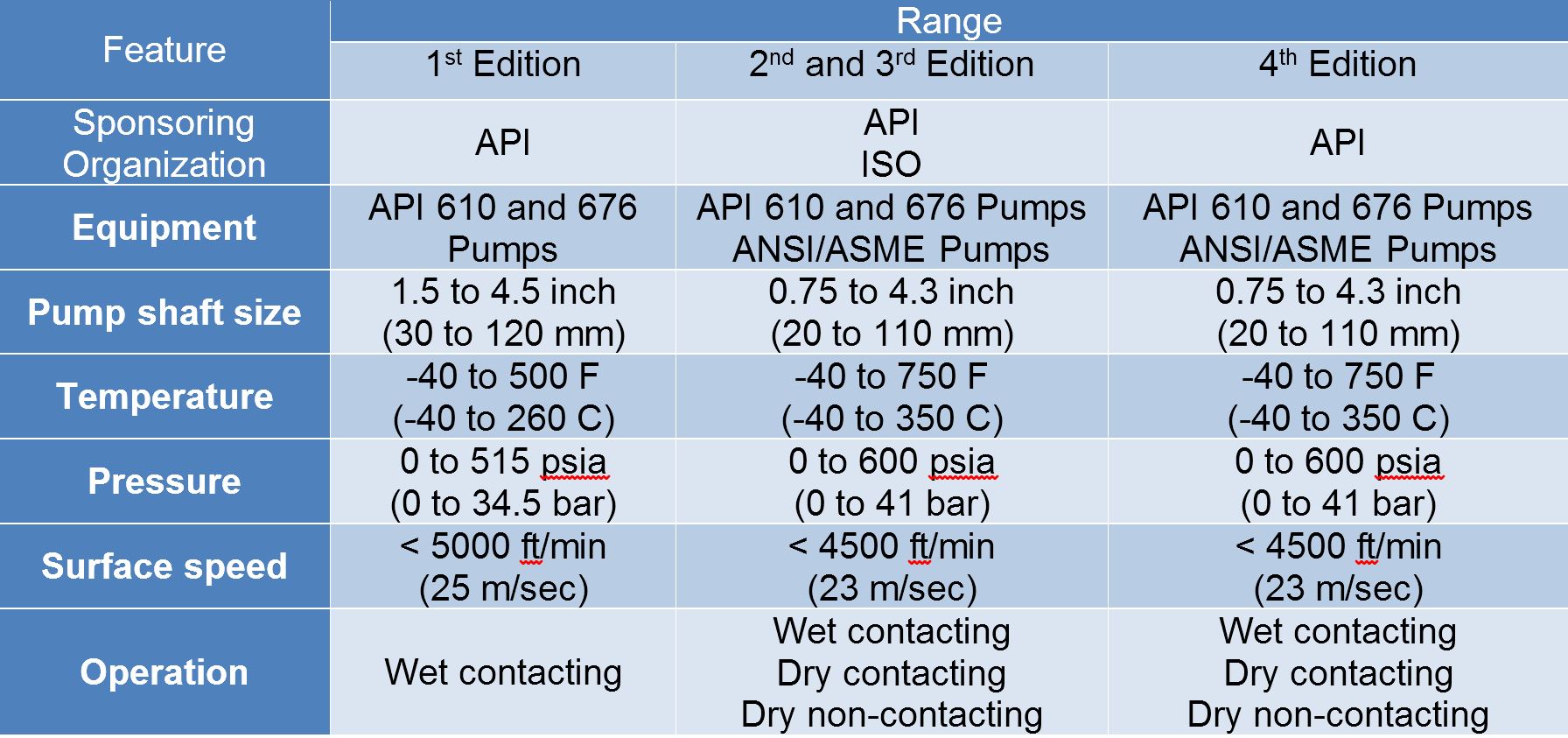

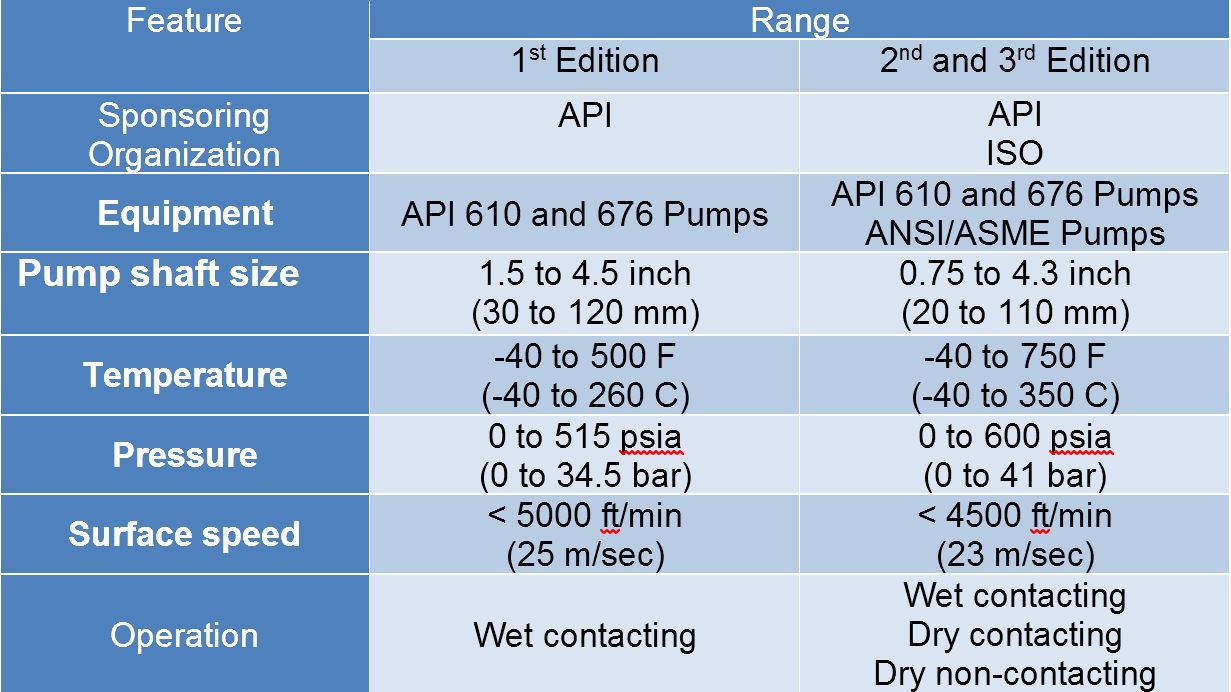

API Standard 682, titled "Pumps - Shaft Sealing Systems for Centrifugal and Rotary Pumps," is the American Petroleum Institute (API) standard for end-face mechanical seals.centrifugal pumps. It is based on the combined knowledge and experience of seal manufacturers, engineering companies, and end users. API 682 is primarily intended for use in the petroleum, natural gas and chemical industries, but is often referenced for other types of equipment and industries.

By the late 1980s, mechanical seals had been accepted as the preferred method for sealing rotating pumps for many years. However, mechanical seal standards were generally buried in other standards such as DIN 24960, ANSI B73, and API 610. All of these standards were primarily pump standards and any references to seals were directed at how mechanical seals would interact with pumps.

API 610 is the API standard about centrifugal pumps and is primarily intended for use in the petroleum, natural gas and chemical industries. Although the 1st through 7th Editions of API 610 included specifications for mechanical seals, beginning with the 8th Edition, API 610 defers to API 682 for seal specifications.

In the late 1980s a group of refinery equipment engineers and managers began to compare sealing solutions in refinery applications. This group, led by V. R. Dodd of Chevron, came up with a general plan and the American Petroleum Institute (API) agreed to establish a standard for mechanical seals: API 682. A Task Force was formed in 1990 and the first meeting was held in January 1991. This Task Force was composed of fourteen members from various refineries, seal and pump manufacturers. API 682, First Edition, was published in October 1994.

One interesting aspect of API 682 is that it includes a strong set of defaults. That is, unless the user indicates otherwise, API 682 makes default choices for specifics such as:

Some statements within API 682 are normative, that is, required, whereas others are informative, that is, descriptive but not required. In particular, many of the illustrations are informative. This distinction has not always been apparent to the reader.

The first edition of API 682 was entirely new although parts of it were extracted from the pump standard API 610 and existing API standard paragraphs.

Although this mission statement no longer appears in the standard, it remains the basic principle driving the work of the API 682 Task Force and its relevance remains the same for the 4th Edition as it did for the 1st.

In addition to providing requirements for mechanical seals, the 1st Edition of API 682 also provided a guide on how to select the correct seal for a number of common refinery applications. In order to provide this seal selection guide, it was necessary to categorize applications into a number of services:

Prior to API 682, 1st Edition, multiple seals were designated as being either “tandem” or “double” seals; however, advances in seal design had rendered these classic terms obsolete. As a result, there was some confusion on how multiple seals were designated. The task force decided to use a more descriptive designation and chose to define dual seal arrangements. A dual seal would be two sets of sealing faces used in the same seal chamber. The fluid between these two sets of sealing faces could be either pressurized or unpressurized. Three standard arrangements were defined:

After having defined the services, seal types, and seal arrangements, a series of flowcharts were created to help in selecting a seal type, special materials or design requirements, and supporting piping plans.

API 682 seals were to have a high probability of three years of reliable service. In order to prove this, seal performance testing on process fluids under representative pressures and temperatures was required. These performance tests are called “Qualification Tests”.

The general idea of the qualification test was to prove that the design was sound. The goal of the qualification test was to simulate a long-term steady state run followed by a process upset. The simulated process upset consisted of pressure changes, temperature changes and included loss of flush. The results of these tests were made available to the purchaser for evaluation. There was no acceptance criteria presented in API 682 1st Edition.

In addition to the qualification test of the design, every API 682 seal, whether new or repaired, is to be pressure tested with air before being shipped to the end user.

One of the major criticisms of API 682 1st Edition was that all the seals were “heavy duty” and therefore expensive with no alternatives for easy services. To some degree, this was intentional and was done in order to reduce inventory, promote familiarity with a limited number of seal types and to increase reliability. Another criticism of API 682 1st Edition was that it considered only API 610 pumps and only refinery applications. The chemical and petrochemical industries routinely use ASME pumps in addition to API 610 pumps. Broadening the scope of pumps covered by API 682 would allow standardized seals to be applied in a greater number of industries.

In 2nd Edition, the organization of API 682 was changed to conform to ISO standards: This reorganization means that there is no simple cross reference guide between 1st edition and 2nd edition paragraph numbers.

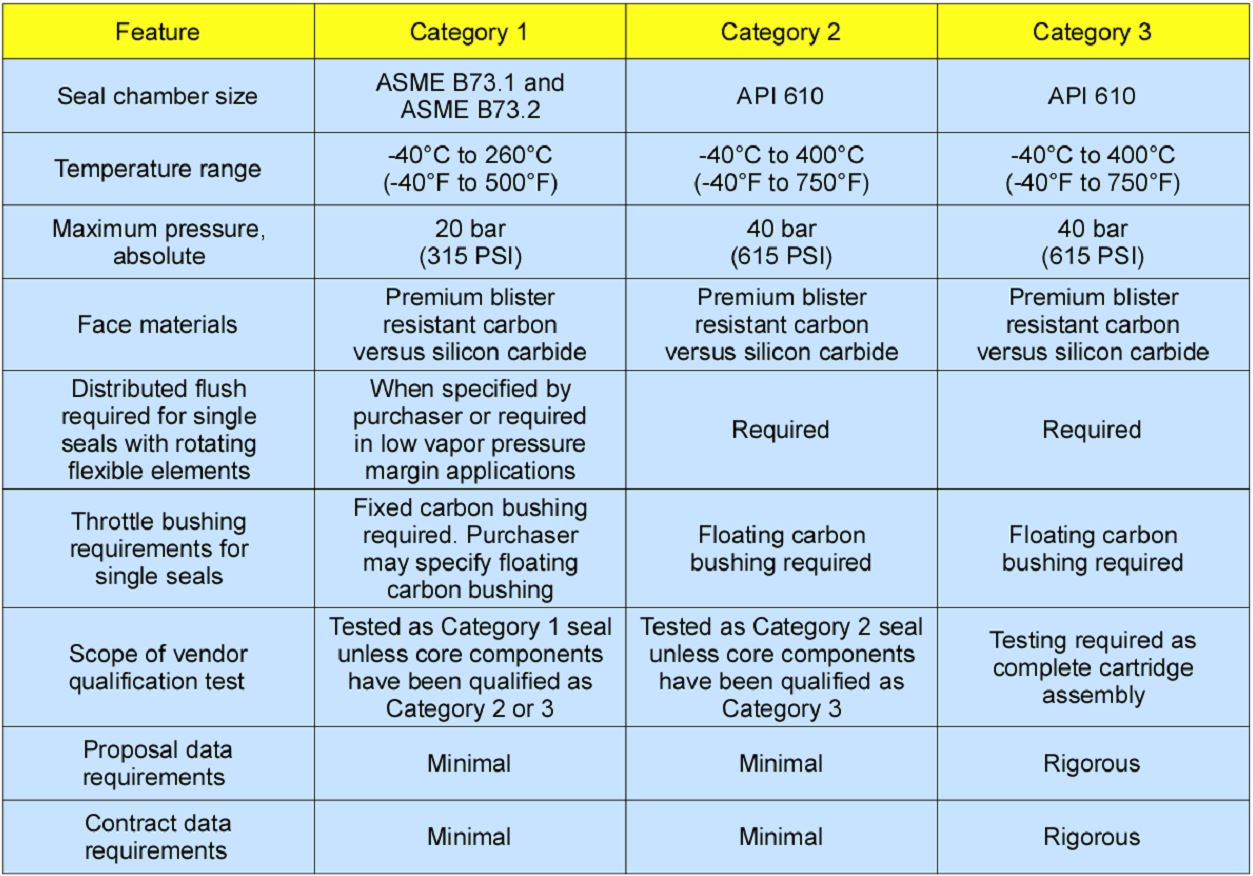

The 2nd Edition introduced the concept of seal categories. A seal category describes the type of pump into which the seal will be installed, the operating window, the design features, and the testing and documentation requirements. There are three categories designated as Category 1, 2, or 3.

Category 1 seals are intended for non-API-610 pumps. This category is applicable for temperatures between –40°F and 500°F (-40°C and 260°C) and pressures to 315 PSI (22 bar).

Category 2 seal are intended for API-610 This category is applicable for temperatures between –40°F and 750°F (-40°C and 400°C) and pressures to 615 PSI (42 bar).

Category 3 seals are essentially the original seals of 1st Edition and are also intended for API-610 pumps. Category 3 seals are intended for the most demanding applications. This category is applicable for temperatures between –40°F and 750°F (-40°C and 400°C) and pressures to 615 PSI (42 bar). Design features include a distributed flush and floating throttle bushing for single seals. Additional documentation must be also provided.

Containment seals are the outer seal of Arrangement 2. In the 2nd Edition, containment seals can be used with a liquid buffer fluid, a gas buffer fluid or without a buffer fluid. In the case of a dry running containment seal, the containment seal will be exposed primarily to buffer gas or vaporized process fluid. Such containment seals must therefore be designed for continuous dry running while meeting the reliability goals of the standard. Dry running containment seals may be either contacting or non-contacting.

Non-contacting inner seals are also introduced for Arrangement 2. One of the primary targets for non-contacting inner seals is in flashing hydrocarbon services. In some of these services, it is impossible to obtain adequate vapor margins to prevent flashing of the fluid in the seal chamber. This seal will be used with a dry running containment seal and the leakage past the inner seal will be piped to a vapor recovery system.

The other new seal type introduced in 2nd Edition was the dry running gas seal used in Arrangement 3. This seal is designed to run on a gas barrier fluid such as nitrogen.

Several new piping plans were introduced in the 2nd Edition. These included additional options for dual pressurized liquid seals as well as new piping plans to support containment seals and dual pressurized gas seals.

One of the strengths of the 1st Edition was to provide qualification tests in which seal vendors would be required to prove the suitability of their seals for a given service. The 2nd Edition expanded on these requirements by adding new tests for containment seals and dual gas seals as well as defining acceptance criteria for all tests.

For all practical purposes, API 682 3rd Edition is the same as 2nd Edition. The completed 2nd Edition was submitted to the ISO Organization for approval as their ISO 21049. At the time, API and ISO had an agreement to jointly issue standards. The ISO Organization made slight editorial changes to 2nd Edition, including correcting typographical errors and unit conversions. Therefore, API had to re-issue a corrected 2nd edition but choose to label it as 3rd edition. API 682 3rd Edition was published in September 2004.

API and ISO no longer have the agreement to jointly issue standards. The 2004 issue of ISO 21049 is the only issue and plans to update it are unknown.

Seal Configuration refers to the orientation of the seal components in an assembly. In previous editions, orientations were defined as face-to-back, back-to-back, and face-to-face and these terms are carried over into the 4th Edition. In 4th Edition, any orientation (face to back, back to back, face to face) can be used in a dual seal provided that the design features are appropriate to the functionality of that particular arrangement.

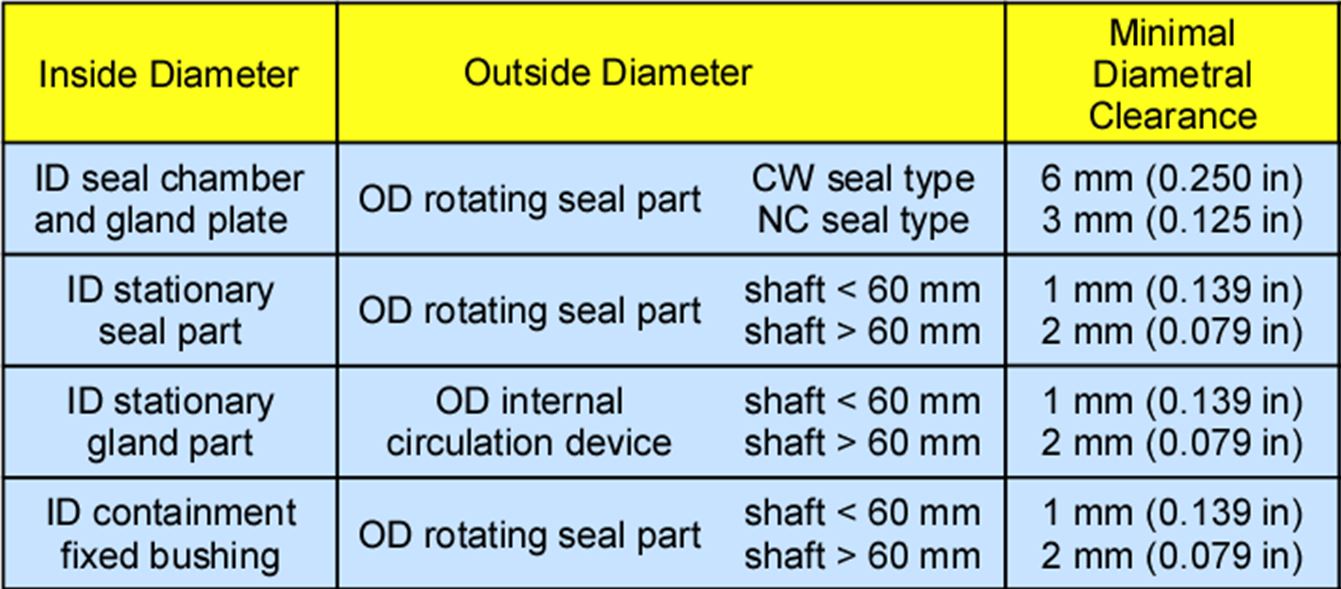

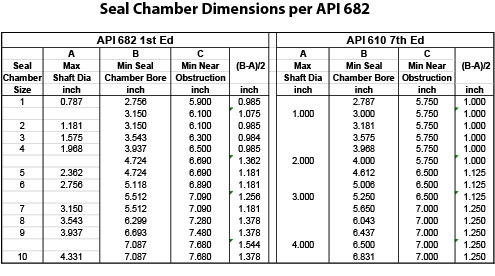

Fourth Edition added additional specifications for clearances, placed these requirements in the form of tables and noted that seal components are not to be considered as “shaft catchers” to restrict shaft movement. The minimum clearances specified apply only to equipment within the scope of the standard. Equipment outside that scope, such as non-cartridge seals, older pumps, non-API 610 pumps and certain severe services, might benefit from larger clearances.

Before API 682, API 610 (the pump standard) used a simple seal code to specify seals. API 682 attempted to use a more comprehensive seal code; however, that code changed with every edition of API 682. The 4th Edition code, described in Annex D, is probably the best to date and includes some concepts and codes from the historical API 610 seal code.

API standards are reviewed every five years and re-issued every ten years. A new Taskforce for API 682 was formed in 2017 and preparations for 5th Edition are underway.

Buck, G. S., Huebner, M. B, Thorp, J. M., and Fernandez, C. L. “Advances in Mechanical Sealing – An Introduction to API-682 Second Edition”, Texas A&M Turbomachinery Symposium, 2003.

API Standard 682, Second Edition, 2001, “Pumps – Shaft Sealing Systems for Centrifugal and Rotary Pumps,” American Petroleum Institute, Washington, D.C.

API Standard 682, Third Edition, 2004, “Pumps – Shaft Sealing Systems for Centrifugal and Rotary Pumps,” American Petroleum Institute, Washington, D.C.

API Standard 682, Fourth Edition, 2014, “Pumps – Shaft Sealing Systems for Centrifugal and Rotary Pumps,” American Petroleum Institute, Washington, D.C.

T - Seal gland type (P = plain, no throttle bushing; T = throttle bushing with quench, leakage and/or drain connections; A = auxilary sealing device, type to be specified) Note: See 2.7.3.21

Please contact AESSEAL Systems Division for further details. Tel: +44 (0)28 9266 9966 Email: systems@aesseal.com For more information, and a video demonstrating the piping plan in operation, select a plan below

OH–Overhung pumps– The impellers of these pumps protrude from the bearings. The support has to take care of all forces, e.g. the overhung mass and the rotor dynamic and hydraulic forces. The impellers of these pumps can be mounted either horizontally or vertically. Its advantages are a single bearing housing and a single seal or packing, but an overhung impeller load is a disadvantage.

The casing can be either axially or radially split, with radially split designs found in tougher applications, such as API-610, where a large gasket area of the axially split design could be a concern for leakage. In fact, axial load is nearly completely eliminated due to impeller symmetry.

(VS) Cantilever– a cantilever design in which only the impeller and casing are submerged in the tank or sump. All joints, including seals, bearings, bushings, and suction check valves, are located out of the fluid. This design is ideal for moving slurries and abrasive solutions that could degrade or interfere with submerged joints.

End Suction Pumps–A straight shot-no turns and bends-is the most efficient way to bring the flow to the impeller, and such designs are called end-suction. In the back, a mechanical seal or a set of packings separates the fluid from leaking out. Following the seal, two bearings support the entire rotor (impeller, shaft, sleeves).

For end-suction designs, the impeller is cantilevered against the inner bearing. On the positive side, there is no restriction to incoming flow, which would be caused by placing one of the bearings at the front side-also called a between-bearing design. Cantilevering the impeller against the inner bearing also helps efficiency and makes the design simple and less expensive (with only one seal).

However, a long cantilevered rotor is prone to deflections, which may overload the bearings and cause seal failures. For this reason, rotor stiffness is an important factor, and designs with bigger shafts (D) and lower overhung length (L) tend to be more reliable. The factor L3/D4, a coefficient of proportionality between force and deflection, is a good measure of comparison between similar designs. The lower the L3/D4, the more robust the rotor-which results in better resistance to deflections.

The API OH1 is a horizontal, foot mounted, single stage, overhung pump with end suction. The pump is mounted to a baseplate and driven via a flexible coupler.

Termomeccanica Pompe AP pumps are single stage, single suction radial impeller, end/top centrifigual pumps for heavy duty services, especially in oil & gas processing. The back pull-out arrangement allows for easy maintenance while the center-line assembly, large diameter shaft, and very stiff bearing casing assure proper alignment of the rotating parts during the most critical conditions. The seal chamber is according to API 682 for any mechanical seal configuration and API 610 for the seal flushing plan.

The API Maxum OH2 is designed for optimum reliability, featuring rugged construction and state-of-the-art mechanical design. Units are well suited for applications that include petroleum refining/production/distribution, petrochemical/chemical processing, boiler circulation/high- temperature applications, and general industrial use. A workhorse in the industry, these pumps are designed for years of service, in some of the toughest environments imaginable.

This model is fully compliant with latest edition API 610 specifications. Standard features include renewable casing wear rings, API 610 seal chamber sized to accommodate 682 mechanical seals, back pull-out construction, dynamically-balanced impellers, heavy-duty carbon steel/finned bearing housing equipped with labyrinth-type oil seals, and fan cooling. Locations are also included for temperature probes, as standard. Common options include single, double or tandem mechanical seals, and various seal flush systems. Heavy-duty baseplates, casing jackets, and various levels of performance testing are also available.

Together, these features combine to produce some of the most efficient hydraulics in the industry and shaft deflection values meeting or exceeding those of API 610 requirements. The API Maxum OH2 is also available as an OH1 design for lower temperature applications.

In a construction using C-6 material there will typically be 400 series stainless steel wear rings in the pump. The pump manufacturer will harden the 400 series rings so that there is at least a 50 Brinell hardness differential between the impeller and casing wear rings which helps prevent galling between the two rings during operation. Running clearance on these rings can be quite high at an elevated temperature. API 610 recommends running clearances greater than the pump OEM manufacturer’s clearances, especially as process temperature increases. High running clearances can provide improved reliability over time. As dry running a pump with metallic rings installed can cause catastrophic failure to the pump in less than one minute, special measures should be taken to prevent dry running the pump when metallic wear rings are installed.

Today there are a number of options on wear ring materials for customers to choose from in lieu of the traditional metal-to-metal ring combinations. Over the past two decades there have been many composite thermoplastic wear ring materials that have been introduced to the market. These composite materials are typically used on the stationary casing wear ring component. The composite material is installed inside of the metal ring as shown here. Composite material is also recommended for the stationary center bushing component on the API 610 BB3 design. Most composite rings can operate up to 500°F, allowing it to operate in most Boiler Feed Water applications.

With a composite wear ring on the stationary ring, running clearances can be taken to much tighter values, when compared to a metal-to- metal ring clearance. For example, the API 610 requires a .020” diametrical running clearance on a ring that is 8.000 inches to < 9.000 inches in diameter. Composite wear rings can accommodate a .011” diametrical running clearance on that same ring dimension. This ultimately improves the efficiency of the pump. In addition to its ability to run a tighter clearance, the composite ring also has a low coefficient of friction. This low coefficient prevents excessive heat buildup during an upset or temporary dry run condition. There are many case studies in the industry which show customers who have prevented a catastrophic and costly pump failure by having composite stationary wear rings installed on their pumps.

Composite rings come at a price. They can often add $15,000-$25,000 to the cost of a large API 610 BB3 pump. I will add that not all composite wear rings materials are created equal. Some will have different radial thermal expansion properties than others. It is encouraged that a pump subject matter expert conduct research before one decides on the type of composite ring material to use. Finally, caution is strongly recommended if using composite wear rings material in fluids with high solids content. If there is heavy scale or high solids in the boiler feed water, it is best to stay away from the composite ring materials. The thermoplastic base material can wear quickly in a high solids environment.

Whenever a new edition of global specifications [e.g., International Organization for Standardization (ISO) and the American Petroleum Institute (API)] is released, there is usually massive confusion surrounding understanding explicit details of the key changes and why they were made. This article addresses five areas of changes that deal directly with pump reliability and maintainability, along with highlighting other various changes incorporated in API Standard 610 12th Edition, Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries, published in January 2021.

Background.API documents are typically updated on a 5-yr interval. API 610 12th Edition had a release date of January 2021, close to 11 yr after the published 11th Edition, primarily due to key items which required some additional time to resolve. The API 610 taskforce began working on this update in 2006. The group addressed the latest developments for rotating equipment, reliability issues, industry issues and proposed changes based upon proven, sound engineering and operating practices. Collaboration with other industry groups such as the Hydraulic Institute, the International Electrotechnical Commission (IEC), the National Electrical Manufacturers Association (NEMA) and ASTM ensured that this document reflected their latest updates. It should be noted that the API 610 12th Edition standard is no longer co-branded with ISO. The 9th, 10th and 11th Editions of API 610 were co-branded as ISO 13709.

The time required for the pump manufacturing industry to incorporate the changes to API 610 in the 12th Edition into their pump designs is difficult to determine. Historically, previous editions of API 610 have transitioned into worldwide usage over about a 2-yr period. Engineers generally will embrace certain changes to API 610 12th Edition because of the benefits presented by these changes, especially regarding the impact on pump reliability. The rest of this article highlights key changes in the standard, with some background explanations.

The annex contains sections for definition; selection criteria for pressure boundary and rotor; design considerations for pressure boundary components, impellers, diffusers or volutes, shaft seals, bearings and bearing housings; materials; manufacturing; and testing guidelines. Product reliability and maintainability is critical for these high-energy pumps. Examples of special purpose pumps are:

For high-energy pumps, every aspect of the design requires careful review, including rotor stiffness, distribution of residual stresses in metal-to-metal sealing surfaces, determination of deflection at critical fits and the establishment of proper running clearances. Performing structural analysis of impellers and diffusers (or volutes) is essential as is determining the proper net positive suction head (NPSH) margin based upon incipient NPSH (NPSHi), not just the generic 3% NPSH3. Especially for new designs, finite element analysis (FEA) of the bearing housing should be done to carefully determine the types of bearings to use. Lastly, the ability to easily assemble and disassemble impellers must be taken into consideration. As for manufacturing requirements, patterns and rigging should provide sound castings while non-destructive testing of highly stressed areas should be performed.

Introduction of API RP 691 Risk Based Machinery Management.API 610 12th Edition now refers to API RP 691—Risk-based Machinery Management—by means of bulleted paragraphs whereby the purchaser needs to advise the vendor when this recommended practice document is invoked. API 691 defines technical readiness levels (TRL) for machinery, with TRLs ranging from conceptual, prototype equipment (TRL 0) to well established, field-proven machinery (TRL 7). When API RP 691 is invoked, the vendor is to advise the purchaser of the TRL of the equipment being offered. API 691 defines high-risk machinery as machinery that handles hazardous liquids or gases, services operating at temperatures of more than 177oC (350oF) and operating pressures of more than 80% of maximum allowable working pressure (MAWP), services operating at temperatures of more than 204oC (400oF), components with TRLs less than 7, liquid services operating at pressures higher than 41.4 bar (600 psig), and liquid services with specific gravity less than 0.5.

API 610 11th Edition required a 20-yr minimum service life. This requirement was replaced in the 12th Edition with requiring only “field proven” equipment to be consistent with other API standards and with the API standard paragraphs. This eliminated any inferred equipment warranty issues.

For several past API 610 editions, a continuous rising to shut-off head curve was mandatory for all pumps. The 12th Edition changed this to be a bullet item for customers to select when they want rising-to-shut-off head curves. However, a note in this bullet paragraph clearly states, “pumps with continuously rising head curve are preferred for all applications, but this is not possible with all pump types.” An example of this is low-specific speed pumps (typically low-flow/high-head, high speed pumps, which have slightly drooping curve shapes, and pumps with multiple radial blade (Barske) design impellers. For pumps operating in parallel, in addition to a minimum 10% rise-to-shut-off mandate, the 12th Edition requires pumps with discharge nozzles larger than 3 in. (80mm) within the preferred operating flow region, to have head values within 3% of each other. These stipulations ensure one pump will not “push” the second pump to shut-off.

Important changes to the API 610 data sheets were made to address all alternate hydraulic operating points: rated and normal (same as before); however, now three additional operating points for customers to advise. These could be for handling a different liquid (as typically found with pipeline pumps or tank farms) or even liquids used to flush pumps during maintenance periods. Most important is that the driver (usually electric motor) is selected to handle the power requirements to handle all these operating conditions, which may have large differences in specific gravity causing an increase in Kw (Hp). Besides data sheets, the 12th Edition introduces a data list, which includes all data found on the data sheets; however, in a tabular form to compile all data into a neutral format to support electronic data exchange (EDE) among contractor, end user and pump manufacturer to minimize possible errors in transposing numbers among all parties.

Pipeline services are characteristic of pumping products with lower product temperatures vs. medium to hot temperature liquids found in refinery services. Because of this, API 610 12th Edition now states the limit for using sleeve/sleeve-ball bearings in pipeline pumps as 8 × 106 kW/min (10.7 × 106 hp/min) after which hydrodynamic radial and thrust bearings are to be used. The 12th Edition also states that for pipeline pumps, with energy density values between 4 × 106 kW/min (5.4 × 106 hp/min) and 8 × 106 kW/min (10.7 × 106 hp/min), hydrodynamic radial bearings shall be used with either rolling-element or hydrodynamic thrust bearings.

New to the 12th Edition is the mandate for shaft guards. Previous API 610 editions, including the 11th Edition, addressed only coupling guards. Inputs from multiple refineries indicated that safety organizations were pointing out that the area between the pump casing cover and the bearing housing has an exposed shaft area that should be covered (FIG. 2). More specifically, this is the shaft area where the mechanical seal gland is located. Furthermore, the drive collar adjacent to the cartridge seal has set screws, which could be a concern if someone placed their hand in that area during pump operation. Basic design for refineries addresses venting to prevent accumulation of seal emissions and a port to measure emissions, whereas for pipeline services a different approach is typically taken.

Options for other designs such as open top-plate, non-grouted and non-grouted with gimble mounts are addressed. The purchaser is to advise which design is required. Designation for Annex D, which provides pre-engineered baseplate sizes, has changed from being normative to informative based on the industry feedback that with today’s enhanced computerized layout of equipment by engineering, procurement and construction (EPC) companies and the quick turnaround by vendors to generate pump general arrangement drawings, this mandate for standardized baseplate sizes has diminished. The 12th Edition states baseplates may have Annex D dimensions if driver, pump size, auxiliaries and seal flush piping properly fit.

A new requirement for OH2 pumps addresses the location for placing auxiliaries in the front region (adjacent to pump suction nozzle area) of the baseplate. This is a major change that improves accessibility for maintenance of single-stage overhung pumps by preventing blocking of the area adjacent to the pump bearing housing, mechanical seal, and coupling and providing easy access to remove the coupling and back-pull-out assembly (including bearing housing and case cover with mechanical seal) for maintenance. This is particularly important for OH2 process pumps with seal reservoirs for Plan 52, 53 and control panels for non-contacting gas seals, along with seal flush plans with coolers such as Plan 23 (FIG. 3). For between bearing pumps, auxiliaries are preferred to be mounted on one side leaving the other side open for easy maintenance.

Definitions, pump pressure ratings.As part of the review process for producing the 12th Edition, Standard Paragraphs—which apply to all rotating equipment—were reviewed. They were compared to the 11th Edition to determine where possible changes in definitions would be required. The definitions needing attention were MAWPand maximum discharge pressure. In both cases, these pressures are now based on maximum specific gravity, and it is the responsibility of the customer to provide this information on the improved format of the API data sheets.

The 11th Edition (as well as all previous API 610 editions) required that OH, BB1 and BB2 pumps be rated for 41 bar (600 psi). The 11th Edition had a special note stating that by the time the 12th Edition is issued, OH, BB1 and BB2 pumps would be required to have a pressure rating equal to that of a PN 40. (300 lb) flange, which is 51 bar (740 psi) at 100°F (38°C). Further discussions revealed that most of these pump sizes generate heads that are relatively low. This translates to the current 41 bar (600 psi) pressure requirement to which most pump manufacturers comply. The final decision was made to revert to the 40 bar (600 psi) rating for these pump types. It should be noted that most manufacturers do have, as an option, higher pressure pump designs, especially for high suction pressure applications which require PN 100. (600 lb), PN 160. (900 lb) and even PN 250. (1500 lb) flanges and heavier wall thickness casing designs.

Explanation has been added to address disassembly after performance testing of BB3 and BB5 pumps to ensure that all water is removed from internal passageways, as water cannot be removed simply by draining for these designs. However, for these multistage pumps, pump disassembly after tests may be invasive to the point of impacting mechanical integrity.

Improved wording and images, diagrams and normative references.One of the main objectives for the API 610 12th Edition task force was to improve wording throughout the document for clarity to assist international users. With this goal in mind, images and diagrams were added to show requirements more explicitly (e.g., baseplate designs), along with expanding the table of contents to include figures and tables, and adding a listing of acronyms and abbreviations

Similarly, a better description of single-stage axial split between bearings BB1 pump classification—foot- or near-centerline-mounted—was added to BB3 and BB4 pumps. “Centerline supported” was added to BB2 pumps. A further clarification was made so that the figures shown generically represent the various pump types and do not reflect actual construction details or certain pump features. This wording was added to help both contractors and end users apply variations of the images without concern. FIG. 6 depicts two additional nozzle orientations for BB1 pumps. FIG. 7 shows a typical top/top nozzle orientation for OH2 single-stage overhung process pumps. This combination was very common in the past, as it provided a cleaner field piping arrangement without typical end suction pump piping obstruction at the ground level, and for modular design systems where space is a premium. These orientations are still purchased today and are not considered as deviations or exceptions to API 610 12th Edition.

Takeaway.This article has touched on the main and other changes from API 610 11th Edition to the 12th Edition. Most of them have impacted pump reliability and maintainability. Changes were made to reflect industry feedback and most end user specification requirements to elevate equipment to a level of minimizing the need of overlay specifications. However, as technology changes and more demanding services arise, the API 610 standard continues to evolve.

Frank Korkowski (korkowskifrancis@gmail.com) is the Manager of Engineered Training at Applied K3nowedge Consulting. He is a consultant recently retired from Flowserve and previously was theMarketingManager for the API 1 and 2 stage process pumps. He spent 45yrin various pump roles with Ingersoll Rand, Ingersoll-Dresser Pumps and Flowserve.Mr. Korkowski earned a BS degree in industrial engineering fromthe New Jersey Institute of Technology,with post-graduate studies in engineering and business administration at Lafayette College and Fairleigh Dickinson University.

Tom Hess (thess@e2g.com) is the Principal Rotating Engineerfor The Equity Engineering Group, Inc. Prior to joining Equity, Mr. Hess worked as aRotatingReliabilityEngineer in an oil refinery.Hehas been fascinated with sealless pumps fornearly30yr. Heearnedhis BSME from Villanova University, is a member of ASME and is a registered professional engineer in the Commonwealth of Pennsylvania. Mr. Hess is a member of the API 685, 610, 682 and 613 Task Forces.

Roger L. Jones (rogerjonessping@aol.com) is a Rotating Equipment Consultant and Task Force Chairmanfor API 610. Mr. Jones spent 32yrin various positions at different Shell companies. In his career,he has held numerous technical and managerial positions in chemical plants and refineries, major capital projects and engineering consulting roles.He earned BS and MS degrees in mechanical engineering from Kansas State University and is a registered professional engineer in Texas. He is the previous chairman of the International Standards Coordinating Committee of the API and head of the U.S. delegation to the various ISO technical committees governing standards for refining and offshore equipment. He is a former member of the International Pump Users Symposium Advisory Committee.

The MP52 series aligns with API 682 Plans 52 and 53A. The Plan 52 is designed to support liquid buffer fluid for a containment seal chamber that is below the seal chamber pressure. The Plan 53A is a pressurized system designed to isolate the seal from the process completely by providing liquid barrier fluid at a pressure higher than the seal chamber.

Our seal reservoirs are built to ASME Section VIII standards and are available with ASME U code stamps. Flexaseal Engineered Seals and Systems, LLC provides standard and custom buffer fluid reservoirs that meet API 682 Standards. As an industrial seal pot manufacturer for the chemical, petrochemical, and industrial industries, our seal pot systems help protect the environment and your workers from hazardous materials.

After more than five years of planning, the American Petroleum Institute (API) is preparing to release the 4th edition of API Standard 682 (ISO 21049:2011). The API 682 standard, which dates back to 1994 and is formally known as Shaft Sealing Systems for Centrifugal and Rotary Pumps, offers specifications and best practices for mechanical seals and systems to pump end users.

The standard’s latest edition began to take shape in 2006, when API formed a 4th edition task force to respond to end users’ questions and comments about previous editions. The task force soon realized that major changes, including reorganization and editing, would be necessary. While addressing every aspect of the resulting 4th edition (which is more than 250 pages long) would be impossible, this article summarizes the standard’s main points.

Those who use API 682 should understand the standard’s scope and remember that the standard does not include specifications for equipment outside that scope, such as engineered seals or mixers. Another important but often misunderstood point is that API 682’s figures are illustrative and not normative in their entirety.

For example, one of API 682’s figures shows a fixed throttle bushing combined with a rotating Type A seal, but seal manufacturers do not always have to combine these two components. The standard provides normative details in clauses and tables to help purchasers distinguish between requirements and suggestions.

The 4th edition continues to divide seals into three categories, three types and three arrangements. For all practical purposes, seal manufacturers can combine a seal’s component parts into nearly any orientation or configuration. Each orientation and configuration has advantages and disadvantages with respect to certain applications, performance and system disturbances.

Before the 4th edition, API 682 did not specify a minimum clearance between the inside diameter of a stationary seal part and the outside diameter of a rotating seal part. The 4th edition specifies this minimum clearance—typically the clearance between the sleeve and the mating ring. The specified clearances are representative of standard clearances that end users have used for decades. End users should not consider seal components to be “shaft catchers” to restrict shaft movement. The minimum clearance specified in API 682 also applies only to equipment within the standard’s scope. Equipment outside that scope, such as non-cartridge seals, older pumps, non-API 610 pumps and certain severe services, might benefit from larger clearances.

The new standard also updates the default bushings for the gland plate for the three seal categories. Fixed throttle bushings are now the default for Category 1 only, while floating bushings are the default for Categories 2 and 3.

While the 4th edition features the recommended seal selection procedure from the standard’s first three editions, it adds an alternative selection method in Annex A. Proposed by task force member Michael Goodrich, this alternative method recommends using material data sheet information to select a sealing arrangement.

Plans 66A and 66B are new to the standard, although end users have used them previously in pipeline applications. These plans detect and restrict excessive leakage rates in case of an Arrangement 1 seal failure.

The 4th edition has revised the data sheets in Annex C extensively to make them the same for all seal categories. Only two data sheets are included in the 4th edition—one in metric units and one in U.S. customary units. The new edition also folds Annex J into Annex E.

Previous editions of API 682 required metal plugs and anaerobic sealants when shipping new or repaired cartridges. After much debate, the task force decided that threaded connection points should be protected with plastic plugs for shipment. These plastic plugs should be red and have center tabs that operators can pull easily to distinguish the plugs from metal plugs. Shippers should also attach yellow warning tags to the plugs to indicate that end users need to remove the plugs before operation.

Although tutorial notes are scattered throughout API 682, this edition expands the tutorial section, Annex F, from seven pages to 42 pages. The expanded annex includes illustrative calculations. In particular, users interested in systems such as Plan 53B will find Annex F to be useful.

The 4th edition of API 682 is the product of more than 20 years of discussion, debate, usage and peer review. It includes a strong set of defaults and is by far the best and most logical starting point for mechanical seal and systems use. Equipment operators should take the time to familiarize themselves with API 682 to get the most out of this comprehensive standard.

![]()

National Pump has a complete line of API-610 type VS-0 submersible, VS-1 sump, and VS-6 canned vertical turbine pumps for the Petroleum market conforming to the latest edition of the API-610 standard. Applications include:

8613371530291

8613371530291