back to back mechanical seal quotation

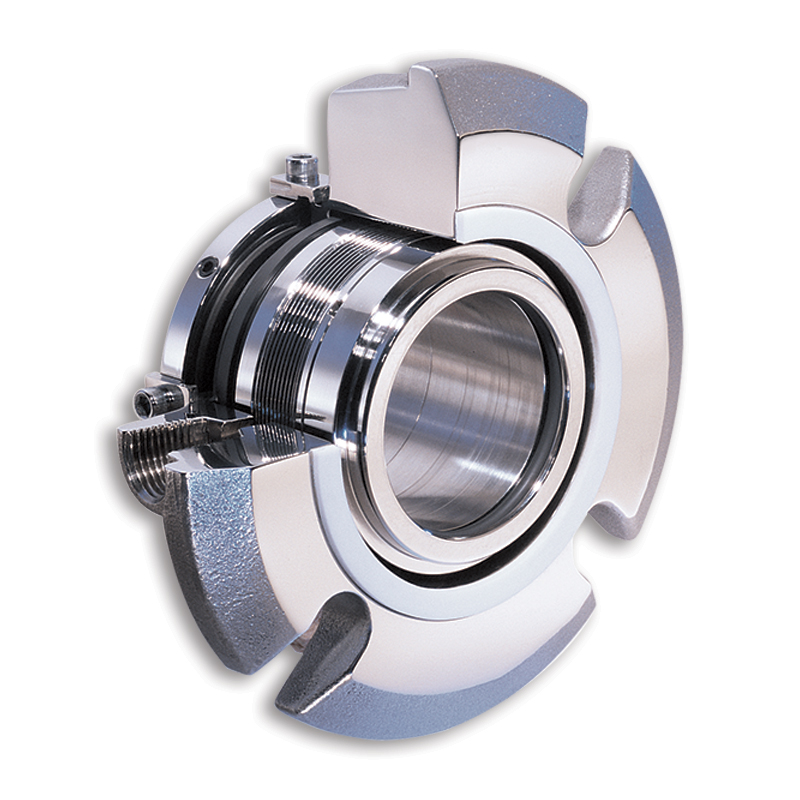

Dual cartridge seals, also referred to as double cartridge seals, are the answer for applications where a second level of protection is needed due to risks to the environment or operating equipment. Flexaseal offers a variety of models that are easy to install while also complying with environmental regulations and ANSI standards. A variety of configurations are available depending on the application and operating conditions.

Flexaseal has replaced traditional cup point set screws with stainless steel drive lugs, resulting in a five-fold improvement in torque transmission strength. And the possibility of sleeve distortion and damage due to over-tightened set screws is eliminated

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time. Contact Flexaseal Engineered Seals and Systems, LLC if in doubt.

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

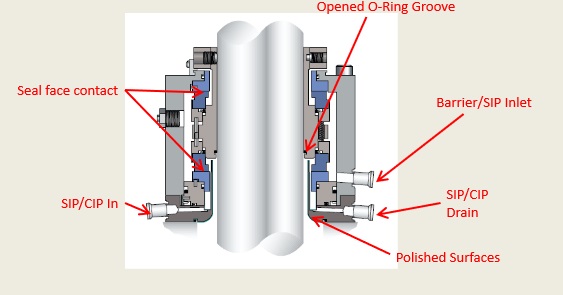

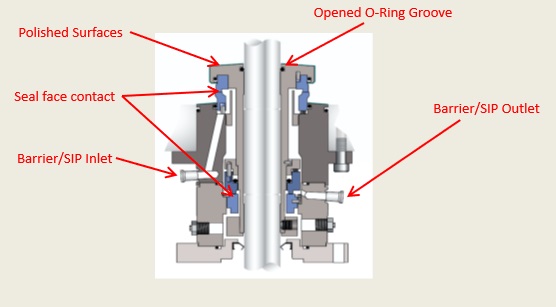

Dual cartridge seals are the answer for applications where a second level of protection is needed. Flexaseal’s Styles 73P & 75P offer system and personnel protection and are designed to ensure compliance with stringent environmental and emissions regulations.

Flexaseal has replaced traditional cup point set screws with stainless steel drive lugs, resulting in a five-fold improvement in torque transmission strength. And the possibility of sleeve distortion and damage due to over-tightened set screws is eliminated

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

The Flexaseal Style 78 tandem cartridge seal is specifically designed for ruggedness and durability to withstand higher temperature or dirty services were leakage and emissions must be completely contained. Design elements include retained faces to allow for pressurized or unpressurized barrier systems, rotating metal bellows for self-cleaning and pilot gland to positively center the seal.

Style 78 is available in a High Temperature (HT) design with static O-Rings or with Grafoil Packing. This allows for operating temperatures up to 800F, while improving reliability by eliminating the dynamic secondary sealing element.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

The Flexaseal Style 79 tandem cartridge seal is specifically designed for ruggedness and durability to withstand services were leakage and emissions must be completely contained. Design elements include retained faces to allow for pressurized or unpressurized barrier systems, stationary design for maximum runout compensation and pilot gland to positively center the seal.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

The Flexaseal Style 80A is designed specifically to conform to API 682 Category 2 Applications for Midstream and Downstream Oil and Gas Applications where a Pressurized or Unpressurized Tandem Arrangement is Desired.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

The Flexaseal Style 90A is designed specifically to conform to API 682 Category 2 Applications for Midstream and Downstream Oil and Gas Applications where a Pressurized Dual Arrangement is Desired.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

In certain processes, dangerous and volatile fluids require additional precautions to protect personnel, ensure safe operation, and prevent downtime. The Flexaseal Multi-Spring Fluid Containment (FCS) Seal has been specifically designed as an economical option for applications where the highest level of safety and environmental control is necessary. The FCS Seal allows monitoring of any primary seal leakage and functions as a secondary containment seal in the event of any primary failure.

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time.

A double mechanical seal is a type of mechanical seal withtwo primary seals or sets of faces, it can operate in various arrangements with a) a barrier (containment) between the sets of faces or b) a buffer (mixing).

2. A Double Mechanical Seal (Barrier) – Wet => is a double seal where the barrier fluid is a liquid. It is generally the most robust seal. It has a good pressure, speed and temperature capabilities.

If you have any query around how to install double mechanical seals for agitators or mixers or have some concerns around the seal failures, why not contact one of our mechanical seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process back up and running reliably again.

The scope of our mechanical seal product range far exceeds any other seal manufacturer. From small elastomer bellows seals used in millions of domestic water pumps to double mechanical seals that ensure maximum sealing safety and large, highly customized dry-running gas seals for mission critical high speed turbo compressors, John Crane has the right product for any application.

Our world-class rotating equipment technologies, paired with an unmatched breadth of applied engineering expertise, meet virtually all international standards including API 682 and help plants reduce maintenance costs, slash down time and improve reliability. When it comes to keeping your rotational equipment running 24/7, John Crane’s comprehensive range of mechanical seals and systems has you covered.

A range of seals for mission-critical applications, designed to solve the application-specific challenges of each industry. From API 682 compliance for the oil and gas industries, using gas seal technology on our innovative pump gas seals to eliminate fugitive emissions, dealing with slurry in the mining and minerals processing industries, to the difficulties associated with maintenance on large pumps and rotating equipment — we have a solution.

Dry-running, non-contacting gas seals have been the industry standard since the early 1980s for turbomachinery. John Crane gas seals, separation seals and support, monitoring, control and conditioning systems — the heart of any reliable sealing solution — are constantly evolving to meet the needs of customers. The product portfolio is supported by unrivaled global service capability providing repair, retrofit, gas seal storage and reliability expertise, delivering total solutions throughout the product lifecycle.

In industries like chemical, pharmaceutical, pulp and paper, and food and beverage, safeguarding and compliance with industry standards, avoiding contamination and efficiency are always top priorities. Our range of vessel and agitator seals optimize equipment performance, maintain product purity and conform to industry regulations, no matter where you are.

Our range of mechanical seals, packing and bearing isolators combines advanced, thoroughly proven technologies with extensive industry expertise to create a range of products characterized by innovative design concepts and outstanding manufacturing quality. Tried, tested and effective solutions for virtually any application that deliver robust performance, reduced installation times and lower maintenance costs.

Create the optimum operating environment that will ensure outstanding seal performance and reliability. Our comprehensive range of engineered pressure reservoirs, gas seal control panels, heat exchangers and abrasive separators can be combined to produce the perfect seal support system for any application.

Designed to overcome rigorous challenges, our comprehensive suite of seal face technologies combat limited seal face lubrication that adversely affects reliability, cost and durability. Our engineers designed these face treatments to extend rotating equipment life through advanced micro machined patterns and features improving seal face lubrication that optimizes equipment performance. We deliver the right face technology for the right application.

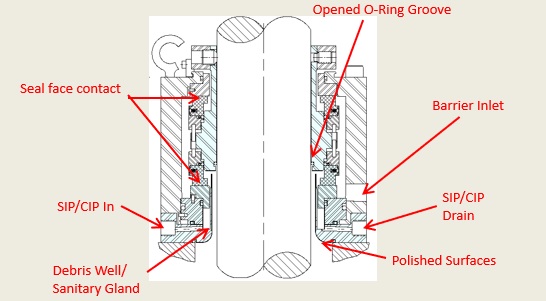

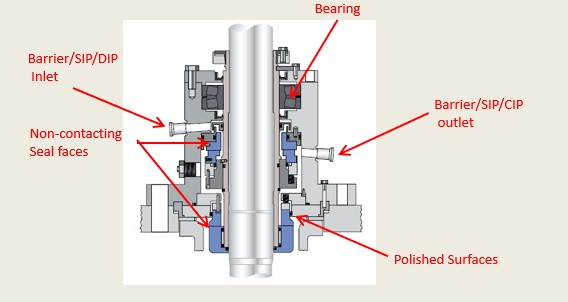

Type 7848 is part of the 7800 Vessel Seal family. The 7800 family consists of heavy-duty, dual pressurized, back-to-back, pusher cartridge seals designed for mixing and agitating equipment. This flexible seal family incorporates modular hardware to provide maximum interchangeability and is available in four different configurations (7828G, 7828GD, 7848W, 7848D), which are specified by the applied seal face technology. Type 7848 is characterized by the use of standard wet seal and special dry running seal faces technology. For details on the non-contacting gas seal versions, please see product description of seal Type 7828.

Type 7848 is available in two variants. The Type 7848W is a conventional wet-running seal that needs an external liquid for lubrication, whereas the 7848D is using special dry-running face materials that allow for application of a gas as barrier fluid. Advantages of contacting dry-running seals include freedom from contamination by barrier liquid at a low face wear rate together with a cost-efficient, easy-to-install (gas) supply system. Wet seals usually can cope with higher pressures and speeds and are less susceptible against solids. Type 7848 is therefore a perfect solution for general purpose and heavy-duty applications.

The 7800 Vessel Seal family was originally developed for the North American market. Therefore, all measurements follow imperial units, and standard designs are available for inch-sized agitator shafts from 1.000" to 5.000". Adaptations to interim or metric-sized shafts are available on request. The Type 7800 Series generally accommodates large amounts of radial run-out. Therefore, an integrated radial bearing is only available as an option for additional shaft stability. For protection against product contamination by barrier fluid or wearing face particles, a debris well option is available.

In Part 2, we’re taking a closer look at the various rotary and stationary double seal arrangement options (configurations), and how to maximize their success.

A double seal is designed with two primary seals. These seals often use two rotating seal faces and two stationary seal faces. A fluid is provided between these two seals at a lower pressure than the sealed fluid (known as buffer fluid) or at a pressure higher than the sealed fluid (known as barrier fluid). The fluid provided to the dual seal allows the seal to survive in lethal, explosive, carcinogenic, hazardous, adhesive, or extremely viscous fluids.

A conventional double seal can be designed to seal the buffer or barrier fluid on the inside or outside diameter of the seal faces. Typically, the seal designer will place a softer, narrow face against a harder, wide seal face. The design intention is to enable the softer seal face to wear, while keeping the wider hard face from wearing in service. Once the narrow seal face has been worn away, the seal has reached the end of its suitable life.

Each configuration has its own strengths which are addressed below. Ultimately, it’s best to speak with a sealing specialist who can draw on a wealth of direct experience and implement according to your organizations’ expectations for reliability and environmental compliance.

In this double seal configuration, two narrow seal faces are mounted back-to-back (opposing) to one another. This is the original concept of a dual seal —taking two component mechanical seals and placing them ‘back-to-back’ within the stuffing box. This configuration is used in most general applications.

The unbalanced back-to-back mechanical seal requires a barrier fluid pressure of 15 psig higher than the seal chamber pressure. The barrier fluid is being pressurized above the seal chamber pressure, so the outboard seal faces are carrying the greater load and should wear out or fail first. When this happens, the barrier pressure will be lost, causing the inboard faces to open. In other words – if the seal works correctly, both seals will fail at the same time. This is not very good back-up protection.

If this seal is a double balanced design, the fluid between the inboard and outboard seal faces can be higher (barrier) or lower (buffer) pressure than the seal chamber pressure. This means that if the barrier/buffer fluid is lost, both seals will remain closed and operate reliably.

In back-to-back arrangement (both unbalanced and balanced seal designs), the outboard seal faces almost always are rated for a lower pressure than the inboard seal faces. This is because the outboard seal faces are an outside seal configuration and the faces are exposed to tensile force. Ceramics are generally weaker in tension than compression, so their pressure limit is lower.

If the inboard seal fails first, the barrier fluid will leak into the process which will cause product dilution. This product dilution sometimes is not desirable for products that can not tolerate it.

This configuration occurs when two sets of seal rings are identically orientated and mounted in-series. This configuration is often referred to as the “in-series seal face arrangement” or “face-to-back.” It is commonly used in dual seals.

In this arrangement, the seals position the barrier or buffer pressure on the outside diameter of the outboard face. The pressure acts to compress the outboard seal faces. This allows a higher barrier fluid pressure.

Face-to-face seals can be used when the equipment is space constrained to accommodate a back-to-back or tandem seal arrangements. In this configuration a portion of the seal is mounted in the seal chamber and the remainder is mounted outside of the seal chamber.

For successful seal life and reliability it is very important to have the right seal arrangement along with the right barrier/buffer fluid system. In upcoming blogs, we will discuss various seal environmental control plans available for double seals and how to select the best barrier / buffer fluid for good seal life to achieve maximum reliability.

Antim Parikh is a Special OEM Projects & Applications Support Manager at A.W.CHESTERTON for mechanical seal product line. He manages the group of mechanical seal applications engineers and OEM platform products/projects.

Antim has worked for the A.W. Chesterton Company for the last six years in the Mechanical Seal product line as Lead Applications Engineer. He has provided support to all field salespeople and customers on product recommendation and troubleshooting. He has also conducted numerous mechanical seal training classes for customers and distributor’s specialists to provide assistance to training group.

Antim holds degrees in Master of Science in Mechanical Engineering (Fluid Power) from CT, USA and Bachelor of Science in Mechanical Engineering from India.

Structural Features: double end, unbalanced, multi spring. The force on the sealing faces are balanced due to the multiple spring design. Back-to-back structure builds up the double seal structure.

Scopes of Application: widely used in many types of pumps and mixers. This component can works as a replacement seal of EagleBurgmann 224UU mechanical seals.

When you need a repair or replacement for your damaged mechanical seals, there are a number of excellent reasons to choose Gaddis Inc. With over forty years of experience in the mechanical seal repair industry, our team of engineers and technicians have the knowledge and experience required to tackle any mechanical seal repair project. This expert team, combined with our state-of-the-art facility and cutting-edge equipment, allows us to offer some of the highest quality mechanical seal repair services that you will find on the market today.

The reasons to choose Gaddis Mechanical Seals for all of your mechanical seal repair needs don’t stop there. In addition to providing unparalleled mechanical seal repairs, we at Gaddis Inc. also strive to keep our rates as competitive as possible. By leveraging our numerous, long-standing relationships with our various suppliers and partners, we are able to pass our savings onto our customers and offer the best value that you will find on the market today. Last, but certainly not least, our dedication to customer satisfaction at Gaddis Mechanical Seals is truly second to none. If you would like to work with a company that is committed to going above and beyond your expectations then the mechanical seal repair professionals at Gaddis Inc. look forward to being at your service!

Multi Spring Double Cartridge Mechanical Sealare widely known high performance seal. This mechanical seals offered by us preassembled and are usually mounted with gland plate on a sleeve which enables it to fit directly over the pump shaft or shaft sleeve in conventional stuffing boxes of any make / type of pump and equipment. For maximum benefit, a seal must be set according to its correct working length, and must be fitted to its right position in the housing with clean face. This type cartridge mechanical seal manufactured by us provides a complete and easy solution to all requirements and easy to install with time saving, even non skilled person can install the seal.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

1. Lepu double mechanical seal animation is manufactured with the help of computerized data acquisition systems which ensure precise measurements of thermal performance and cooling effects.

3. Guangzhou Lepu Machinery CO., LTD review and manage suppliers together with R&T and Procurement, ensure double mechanical seal arrangement meet double mechanical seal animation management requirement.

Back to back: Two rotating seal rings are arranged facing away from each other. The lubricating film is generated by the barrier fluid. This arrangement is commonly found in the chemical industry. In case of leakage, the barrier liquid penetrates the product.

Face to face:The spring loaded rotary seal faces are arranged face to face and slide from the opposite direction to one or two stationary seal parts. This is a popular choice for the food industry, particularly for products which tend to stick. In case of leakage, the barrier liquid penetrates the product. If the product is considered “hot”, the barrier liquid acts as a cooling agent for the mechanical seal.

Users can choose different material for this double mechanical seal 208, matching for different liquid conditoncarbon, silicon, and tungsten carbide for this mechanical seal as seal face, if for high temerperature, we suggest to choose rubber seal viton for the rubber parts.

Lepu seal make this dual mechanical seal for many years, and offer professional suggestion when client need this grundfos seal, so we are your reliable specialist for grundfos mechanical seal.

Double mechanical seals are commonly used in the following circumstances:If the fluid and its vapors are hazardous to the operator or environment, and MUST be contained

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

3. We"ve fostered a culture which is based on openness, honesty, integrity, and fairness. And we empower our people to go beyond what is required to meet legal and regulatory obligations. Get price! We will continue to focus on driving down our emissions from energy as well as look at improving the way we collect data on our resources use, for example, waste and water. Get price! We minimize the negative impact of our production activities and promote both recovery and environmental-protection projects. We are developing new technologies in order to avoid unnecessary resource consumption.

Seal Type 532/D and 532/D/B Mechanical Seals are designed for Bottom and Side Entry Drives in Reactors. Compact Economical Cartridge Double Mechanical Seal. The design may either without bearing (Type 532/D) or with integral bearing (532/D/B). Complete Pre-assembled Tested Unit ready for installation. These Seal are used for Exclusive Solid Seal Faces, Stationary Seats, thus Lowest Level of Seal Face distortion when Expose to Compressive Load and Thermal Pressure.

8613371530291

8613371530291