barrier fluid for mechanical seal manufacturer

Lubriplate Barrier Fluids are ultra-clean, polyalphaolefin (PAO) synthetic based fluids recommended for all types of mecahnical seals. While they are NSF H1 registered food grade, they may be used for all applications requiring barrier fluid for mechanical seals.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Barrier Fluid FDA is a pure, non-reactive, synthetic fluid that provides superior lubrication and cooling for double and tandem mechanical seals. Barrier Fluid FDA provides very stable seal performance over an extremely wide temperature range, satisfying most seal service requirements. Barrier Fluid FDA is extremely clean and has excellent low temperature fluidity and heat transfer properties. Barrier Fluid FDA is sanctioned under the FDA CFR Title 21 Sections 178.3620(a)(b); 172.878; 175.105; 176.200 and 210; 177.2260, 2600 and 2800; 178.3570 and 3910. It is NSF Certified for H1 service. Barrier Fluid FDA is essentially inert, allowing it to be used with most hydrocarbon gases and aqueous acids and bases. Barrier Fluid FDA is an undyed product.

Barrier Fluid FDA is a pure, non-reactive, synthetic fluid that provides superior lubrication and cooling for double and tandem mechanical seals. Barrier Fluid FDA provides very stable seal performance over an extremely wide temperature range, satisfying most seal service requirements.

Barrier Fluid FDA is extremely clean and has excellent low temperature fluidity and heat transfer properties. Barrier Fluid GT is recommended for use at elevated temperatures where a nitrogen purge is not an option and when FDA purity is not required.

DuraClear Crystal 7 Seal Lubricant is a premium barrier fluid for use on equipment handling high purity, high value or highly reactive product fluids such as strong acids and bases. It has been specifically formulated for the lubrication needs of dual mechanical seals. When chemical compatibility is critical, this environmentally friendly and nonreactive barrier fluid extends the life of dual mechanical seals for increased process yield and throughput.

CTFE fluids may react violently with K, Na, amine, hydrazine, liquid fluorine, liquid chlorine trifluoride, Aluminum, Aluminum Chloride (AlCl3) and Aluminum Oxide (Al2O3)

As end users face increasingly restrictive leakage and safety regulations, a growing number are turning to multiple seal arrangements. Multiple sealing arrangements require a liquid or gas buffer or barrier fluid to operate, introducing a new factor that end users must monitor.

Below are some best practices for liquid buffer and barrier fluids. By selecting an appropriate fluid and following proper maintenance procedures, end users can promote system reliability and extend their systems’ operating lives.

In addition to process fluid, all multiple seals use an external fluid. Depending on the sealing arrangement, this external fluid is called buffer fluid or barrier fluid. American Petroleum Institute (API) Standard 682 specifies that unpressurized dual seals, also known as traditional tandem seal arrangements, use buffer fluid. Pressurized dual seals, on the other hand, use barrier fluid, which isolates the pump process liquid from the rest of the system.

When selecting a fluid, end users should weigh the pros and cons of their applications. Some common barrier and buffer fluids, which have benefits and potential risks, are:

Glycol solutions — These, which usually contain 50 percent ethylene glycol and 50 percent water, are the simplest and most common barrier or buffer fluids. Because inhibitors can come out of the solution and damage the seal faces, end users should use uninhibited glycol in these solutions instead of glycol with inhibitors, such as antifreeze. Since some areas restrict the use of ethylene glycol, end users may need to use propylene glycol instead.

Petroleum-based hydraulic, conventional gear and bearing lubricating oils — Because they are widely available, they are popular choices. However, the viscosity of these oils can cause carbon seal face blistering, particularly with oils that are Grade 32 or higher on the International Organization for Standardization (ISO) scale.

Synthetic oils specifically formulated for barrier or buffer use — These have grown increasingly popular during the last decade. These synthetics are typically polyalphaolefin-based, and they range between ISO Grade 5 and Grade 20 (approximately). Lower-viscosity synthetics are the most popular option among end users. Higher-viscosity synthetics, which are more expensive, are the best choice for applications with high temperatures or low shaft speeds.

Heat transfer fluids — Although useful in extremely high-temperature services, these fluids can pose problems because they tend to decompose and form coke, or hard carbon formations.

After choosing the correct fluid for their system, end users must maintain the fluid and the sealing environment properly to ensure peak performance. Checking the fluid each month for changes in pH, color, viscosity, consistency and the presence of solids is a good way to help promote system reliability.

While users should change their barrier and buffer fluids regularly, service life can vary dramatically. In general, fluids operating at high temperatures need changing more frequently than those at lower temperatures.

According to API 682, the allowable temperature rise is 15° F for systems with buffer or barrier fluids that are water-based, diesel or kerosene, and 30° F for systems that use mineral or synthetic oil as buffer or barrier fluids. For example, a system using oil could have an average reservoir temperature of 130° F with an outlet temperature of 115° F and an inlet temperature of 145° F.

When monitoring the decomposition of buffer or barrier fluids, end users should consider this rule of thumb for chemical reactions — the rate of reaction doubles for every 18 F rise in temperature. For example, if a barrier fluid needs changing every six months at an average reservoir temperature of 130° F, the same fluid would need to be changed every three months if the reservoir temperature is 148° F. This simple guideline can be useful for evaluating heat transfer options during system design.

In addition to temperature considerations, buffer fluids can become contaminated by the process liquid and may require more frequent changing than barrier fluids.

While selecting the proper buffer and barrier fluid is an important first step toward sealing system reliability, the following considerations also have a big effect on performance:

API 682 provides useful guidelines and default selections for standardized dual seal systems — including Piping Plans 52, 53A/B/C and 54. By combining the API guidelines with the best practices for buffer and barrier fluids described in this article, end users can keep their systems operating smoothly.

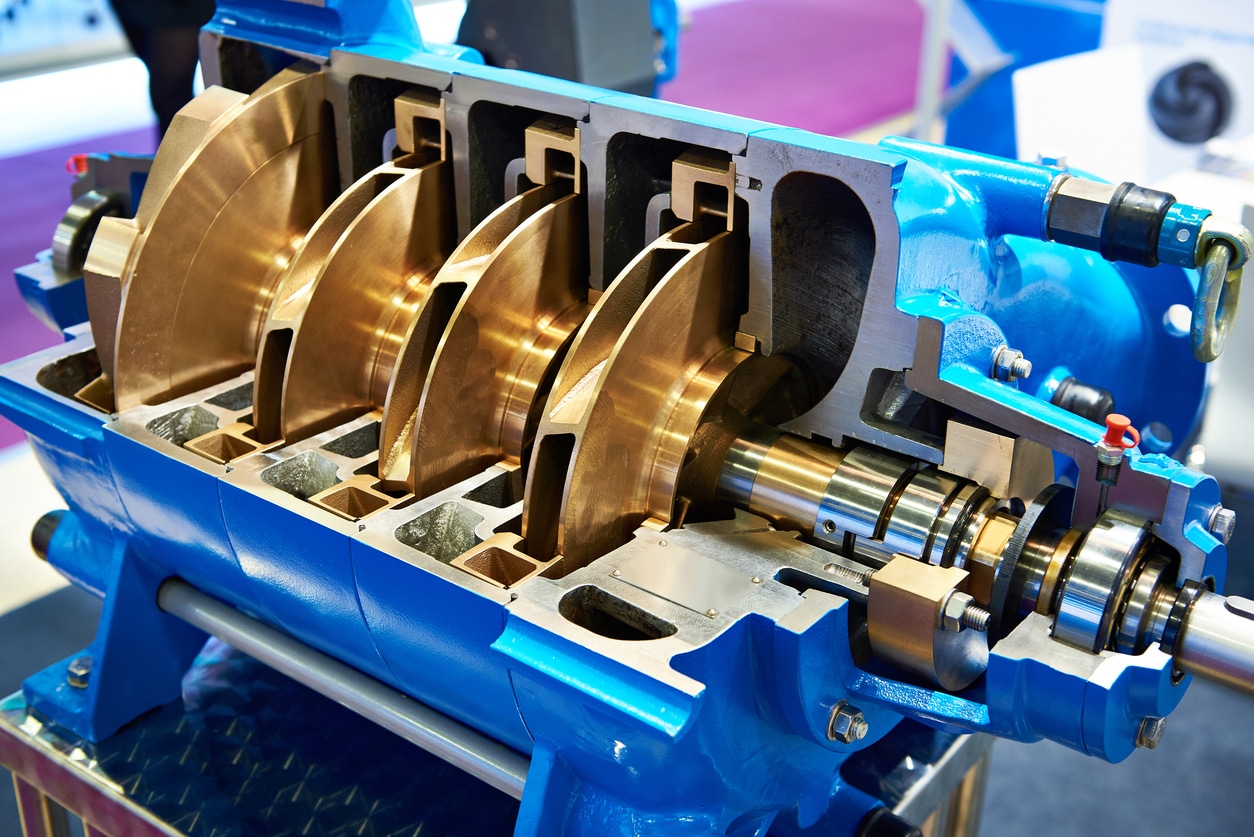

As operators of pumping equipment become more focused on the safety, reliability and environmental impact resulting from shaft seal leakage, dual mechanical seals have become more prevalent in the industry. A dual mechanical seal offers a second (outer) seal to contain the pumped fluid by creating a cavity or chamber between the inner and outer seal that can be filled with a fluid. When this fluid is unpressurized, it forms a buffer between the pumped fluid and atmosphere and is commonly referred to as a buffer fluid. When pressurized, it forms a barrier between the pumped fluid and atmosphere and is known as a barrier fluid.

Although mechanical seal designs are available in configurations that use either a liquid or a gas as a barrier fluid, the following discussion focuses on liquid buffer and barrier fluids only. In addition to separating the pumped fluid from the atmosphere, liquid buffer and barrier fluids lubricate the mechanical seal and transport frictional heat and absorbed heat from the mechanical seal to a heat exchanger. This controls the fluid’s temperature and lubricating properties.

Buffer/barrier fluid can be stored, monitored and delivered using many methods. Each is identified by a piping plan number that describes the minimum requirements of each system. The most commonly referenced piping plan originates from the American Petroleum Institute’s standard API 682.

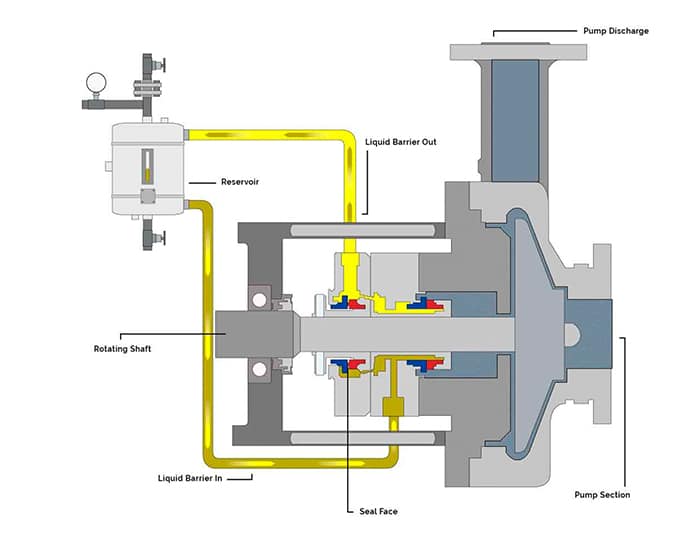

A Plan 52 system (see Figure 1) provides a reservoir that stores the buffer fluid. Supply and return lines are connected to the mechanical seal and circulation of the buffer fluid is achieved by an internal circulating device (pumping ring) within the mechanical seal. The vapor space above the buffer fluid in the reservoir is vented to atmospheric pressure typically via a flare or vapor recovery system. The reservoir can be instrumented to measure the liquid level and pressure in the reservoir. Ports are fitted to the reservoir to facilitate maintenance activities—such as inspection and cleaning or refilling and draining the buffer fluid. Cooling is accomplished using an internal heat exchanger.

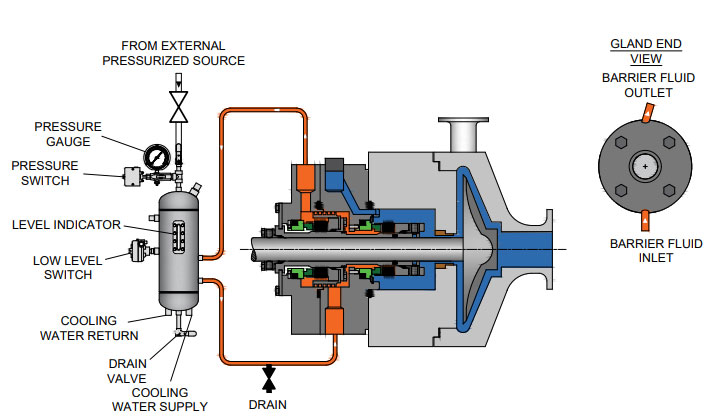

Pressurized dual seal systems contain the same essential components as an unpressurized system. However, they also contain a way to pressurize the barrier fluid. The following plans may be used for pressurized dual seal systems:

Plan 53A—A pressurized gas blanket in the reservoir pressurizes the fluid. Nitrogen is normally used and the pressure is controlled via a pressure regulator (see Figure 2). The barrier fluid is in direct contact with the pressurized gas.

Plan 53B—Pressure is generated as a nitrogen-filled bladder is compressed by the addition of barrier fluid into the bladder accumulator. The bladder prevents direct contact of the pressurized gas with the barrier fluid.

Plan 53C—A pressure amplifying piston uses pressure from within the pump (typically the seal chamber) to amplify the barrier pressure by the ratio of the area on each side of the piston. The barrier fluid is not exposed to any pressurized gas.

Plan 54—An external system is used to pressurize and circulate the barrier fluid. A Plan 54 system can be broadly classified into two groups: closed- and open-loop systems. In closed-loop systems, the barrier fluid is stored in a large reservoir and pumps pressurize and circulate the fluid. In open-loop systems, a compatible process stream is used as the barrier fluid and is circulated through the mechanical seal and returned to another point downstream in the process.

Several critical properties of a buffer or barrier fluid must be considered when making a selection. An ideal buffer or barrier fluid will have the following properties:

Water offers several benefits as a buffer/barrier fluid. Its thermal conductivity is about three times greater than oils and its specific heat is about twice that of oils, so it is good at transporting heat away from a mechanical seal. Water is inexpensive, easy to handle and store, has few seal material compatibility issues and is nonflammable. It is also compatible with many aqueous pumped solutions. Its viscosity is generally around 1 centistoke at moderate temperatures which offers low resistance to flow in the barrier system.

However, the viscosity becomes low at elevated temperatures limiting its effectiveness as a lubricant for the mechanical seal faces. Water is also susceptible to freezing during the winter months. This results in a narrow window of service and environment temperatures in which water can be used.

Generally, oils can be used in a much wider range of service temperatures. Compared to water, oils offer greater fluid stability at elevated temperatures and are not susceptible to freezing. They also provide excellent lubrication of the mechanical seal faces and, therefore, have the potential to offer longer seal life. Few compatibility issues with mechanical seal materials exist.

Oils are available in a wide range of types, compositions and viscosities. Traditional oils used in the industry include turbine oils and automatic transmission fluids. However, performance as buffer and barrier fluids has not been as successful as other oils, primarily because of the complex mixture of additives in these fluids.

Good performance can be achieved from oils with viscosity below that of ISO Grade 32 oils. High viscosities can result in damage to the mechanical seal faces, particularly when carbon is used as a face material. Paraffinic-based oils also generally perform better than naphthenic oils while synthetic oils offer even better performance. Synthetic lubricants specifically developed for use as a buffer/barrier fluid are now available in the marketplace and offer excellent performance. However, this performance is achieved at the sacrifice of cost.

We invite your suggestions for article topics as well as questions on sealing issues so we can better respond to the needs of the industry. Please direct your suggestions and questions to sealingsensequestions@fluidsealing.com.

Tegra Synthetic Barrier Fluid is designed to meet the needs of a barrier fluid for dual mechanical seals per API Standard 682, Shaft Sealing Systems for Centrifugal and Rotary Pumps. Dual mechanical seals are used to control emissions of volatile air pollutants from industrial equipment. Leading seal manufacturers recommend the use of low viscosity synthetic fluids for extended seal life of API Standard 682 dual mechanical seals.

Tegra Synthetic Barrier Fluid 17 cSt has a low Volatile Organic Compound (VOC) level, so that the barrier fluid itself will not be the source of volatile air pollutants in higher temperature applications.

Chesterton 662 FG is an ISO VG Grade 22 high-performance lubricant designed specifically as a barrier fluid for double mechanical seal applications. 662 FG is suitable for all industrial and food/beverage/pharmaceutical applications. 662 FG is NSF H1 registered.

The ultra-clean 662 FG delivers premium thermal stability while minimizing the abrasive-particle wear of the seal faces and extending equipment life.

DALLAS – March 7, 2016 – Hydrotex, a national manufacturer and distributor of high performance lubrication and fuel improver solutions, announced today it is introducing two new synthetic barrier fluids: Hydrotex Economy Barrier Fluid, for cost-sensitive applications, and Hydrotex Performance Barrier Fluid, for extended lubricant life and improved low-temperature fluidity. Both fluids outperform the leading competitor in providing superior lubrication and cooling for tandem and dual mechanical seals, as proven through testing by a major mechanical seal manufacturer.

For maintenance and reliability professionals in the refining, chemical processing, and food processing industries, Hydrotex Barrier Fluids ensure the performance and extend the life of expensive cartridge seals. These barrier fluids are also approved for incidental food contact under FDA Regulation CFR 178.3570, Lubricants with Incidental Food Contact and NSF H1 approval is pending.

Mechanical seals, which can number in the hundreds in a typical refinery or plant, are critical in the process of separating and controlling hazardous chemicals, maintaining the integrity of food ingredients and ensuring cleanliness and purity throughout the manufacturing processes. The reliability of each seal also safeguards worker safety and environmental compliance.

“These barrier fluids fill a performance gap,” said John Cummins, vice president, product technology. “Previously available products worked for a short time but didn’t provide long-lasting leak protection.”

Hydrotex Barrier Fluids are available through local Hydrotex representatives. To find your representative, please check www.Hydrotexlube.com or call 1-800-527-9439.

Hydrotex helps customers develop sustainable solutions designed to improve system reliability, save energy, limit pollution, extend fixed asset life, reduce maintenance costs and improve fuel efficiency. Its products and services leverage 80 years of innovation resulting in superior lubrication solutions and high touch customer service. For more information and to find your local Hydrotex consultant, contact www.hydrotexlube.com

Our barrier seal reservoirs are built to ASME Section VIII standards and ASME U code stamps are available. All our barrier fluid systems, whether custom or standard designs are designed and built to the current API 682 requirements.

Water is readily available. It is environmentally acceptable and has no health and safety restrictions. It also has a high specific gravity and specific heat which aids in heat transfer. For all of its favorable properties however, water has severe limitations as a barrier fluid. Pure water is a poor lubricant. At ambient conditions, water has viscosity that is suitable for lubricating seals with carbon vs hard face combinations. The viscosity decreases rapidly as the temperature increases. By 71°C (160°F), the viscosity is low enough that the fluid film in a standard seal fails to support the face often resulting in higher wear rates. The low viscosity of water can also create problems for Plan 54 systems.

This article is an excerpt from a paper, "Barrier and buffer fluid selection and considerations for mechanical seals" by Michael Huebner of Flowserve Corporation at the 2016 Turbomachinery & Pump Symposium.

Many Plan 54 systems are designed as an open system and use a positive displacement pump to create pressure and circulate the barrier fluid through the system. Many of these positive displacement pumps are designed with rubbing or sliding pump components that are designed to operate on a lubricating fluid. Operating these pumps on water can greatly reduce the reliability of the Plan 54.

Water at low temperatures can introduce different concerns. At 0°C (32°F), water freezes. This can have a severe impact on the condition of the seals and the auxiliary components. When a pump is in operation, the water barrier fluid may be heated by the process or the seal generated heat. In standby service though, the barrier fluid may reach ambient temperature conditions. Water is relatively non-corrosive but it will rust wrought and cast carbon steels. Normal seal piping plans will use stainless for most components but may use carbon steel for the reservoir to reduce cost.

Water barrier or buffer fluid systems must be designed with non-rusting materials. Not all water supply systems have clean, pure water. Contamination in the systems (e.g. rust or dirt) as well as water treatment chemicals (e.g. descalers, rust inhibitors, biocides, etc.) may affect chemical compatibility of the seal components or the lubricating properties between the seal faces. Users must ensure that the water supply is clean and suitable as barrier fluid.

One of the primary reasons why water is selected as a barrier fluid is for compatibility with the process fluids. In normal operation, small amounts of barrier fluid will leak into the process. In some processes, pure water introduced into the system would not be considered as a contaminant in the process. Water, specifically condensate, is the most common barrier fluid in the food processing, pharmaceutical, and biotech industries.

Many of the shortcomings of water can be addressed by mixing the water barrier fluid with other chemicals. The most common mixtures are water with either Ethylene Glycol (EG) or Propylene Glycol (PG). The addition of a glycol to the water depresses the freezing point and elevates the boiling point. It also increases the viscosity of the mixture which can provide better lubrication to the seal faces. It does this while still maintaining the high specific gravity and specific heat required for effective heat transfer. The improved properties made this buffer fluid an industry standard in refineries in light hydrocarbons services for many years.

Ethylene glycol is commonly used as a heat transfer fluid in industrial applications and automobile cooling systems. Automotive anti-freeze is most commonly a mixture of EG and other chemical additives. These other additives provide useful properties to automotive applications including preventing rust and corrosion, descaling metal surfaces, and stopping leaks in the cooling system. While these additives enhance the performance in automotive applications, they can cause high wear on the seal faces and reduce the reliability of the seal. For this reason, automotive anti-freeze should not be used in barrier or buffer fluid systems. Only pure EG or PG should be used. While ethylene glycol improves the properties of the barrier fluid, it has the drawback of being mildly toxic. Casual exposure to the skin is not considered a significant hazard but it must not be ingested and leakage into the environment may be regulated. For these reasons, many users have switched to propylene glycol/water mixtures. The properties of PG/water and EG/water are comparable and they will provide similar performance in most applications.

Propylene glycol is considered non-toxic and is safe for human exposure. Food grade PG is available and can be used in many food handling processes. Propylene glycol should be the first choice for glycol/water barrier and buffer fluids in most applications.

Welcome back to blog post #2 in the Seal Support Systems series! The first blog post in the series explored the various types of Seal Support Systems, the very common flush-type plans, and using API 682 for proper selection. Seal Support Systemshelp ensure peak performance of mechanical seals in process pumps, and different types of plans are required for different pump applications. This post focuses on Buffer and Barrier Plans.

Buffer and Barrier Plans use a circulating liquid or gas as a buffer or barrier between the process fluid and the atmosphere. These plans are often associated with the use of a secondary mechanical seal, further reducing the risk of process fluid to the atmosphere. This use of a dual seal means that a seal plan may require the combination of a flush plan for the primary seal, as well as a buffer or barrier plan for the secondary seal.

The primary difference between a Buffer and Barrier Plan is whether the Seal Support System is pressurized and therefore whether leakage over the seal is inboard or outboard. For a Buffer Plan, the seal support system provides an unpressurized fluid to the seal chamber which acts as a buffer between the process and the atmosphere. When process fluid leaks across the mechanical seal, it will be "captured" within the buffer fluid and is prevented from exiting the seal chamber. Conversely, a Barrier Plan provides pressurized fluid to the seal chamber, creating a more direct "barrier" to the leakage of the process fluid. This is accomplished by pressurizing the barrier fluid above the seal chamber pressure. In short, Buffer Plans are normally used where process fluid leakage should be minimized and contained, whereas Barrier Plans are used when no leakage to atmosphere can be tolerated1.

Within the categories of Buffer and Barrier Plans, some variations are available that provide benefits to certain applications. One of the most common plans is Plan 52, which is an external seal pot containing an unpressurized seal fluid. An example of a Plan 52 is shown in Figure 1 below.

Similar to the Plan 52 for Buffer Plans is the Plan 53 for Barrier Applications. Plan 53 is available in three common configurations which utilize different methods to achieve pressurization. Plan 53A uses a seal pot like Plan 52, however the seal pot is pressurized using a blanket of nitrogen gas. Alternatively, Plan 53B uses a pre-pressurized bladder accumulator, which has the benefit over Plan 53A of not allowing gas absorption into the barrier fluid. Plan 53C uses a third type of pressurization source, a piston accumulator. This unique arrangement is driven by a sensing line from the seal chamber, allowing for a constant pressure differential to be maintained between the seal chamber and the barrier fluid. An example of a Plan 53B is shown in Figure 2 below.

Plans 52 and 53 both rely on positive circulation within the circuit using a pumping ring. In certain cases, a larger, external Seal Support System is required that makes use of a pump and an external reservoir. This is demonstrated by Plan 54 (pressurized) and Plan 55 (unpressurized), which also make use of other complementary components such as filters, coolers, and other items. An example of a Plan 54 is shown in Figure 3 below.

Finally, Buffer and Barrier Plans may also make use of gases. Plan 72 supplies a buffer gas, typically nitrogen, from an external source to the seal chamber. These plans often include the use of filters, pressure regulators, and flowmeters to ensure the gas is in the appropriate condition for the mechanical seal. Alternatively, Plan 74 supplies barrier gas, which is pressurized above the seal chamber pressure.

It is important to note that Gas Seal Support Systems are only intended to be used with mechanical seals that are designed for use with gas seal fluids. Additionally, it is common to pair the Plan 72 with an associated leakage collection Plan 76, which collects the gas mixture exiting the seal chamber. An example of a Plan 74 is shown in Figure 4 below.

In addition to the various seal plan arrangements used for buffer and barrier seal applications, there are further best practices and options that may be employed. For example, a Plan 53 may use a water or air cooler to ensure heat dissipation from the seal fluid circuit. Other common best practices are recommended in the 4th edition of API 682, including the use of block and bleed valves with measurement devices and the use of pressure, temperature, and level transmitters and switches1.These best practices and options help to ensure proper mechanical seal operation, reliability, and safety.

Our global team of Field Engineers are also available to help you achieve safe and reliable Seal Support Systems through our OnsiteandVirtualFluid System Evaluation and Advisory Services.

8613371530291

8613371530291