bellow type mechanical seal quotation

John Crane brings you the world’s most complete selection of performance-proven edge-welded and formed metal bellows sealing products used in a wide range of rotating equipment such as pumps, compressors, mixers, and agitators. Our experience in diverse industries such as oil & gas, petrochemical, chemical, refrigeration compressor, pharmaceutical, food processing, pulp & paper, and more have proven the soundness of John Crane’s metal bellows design.

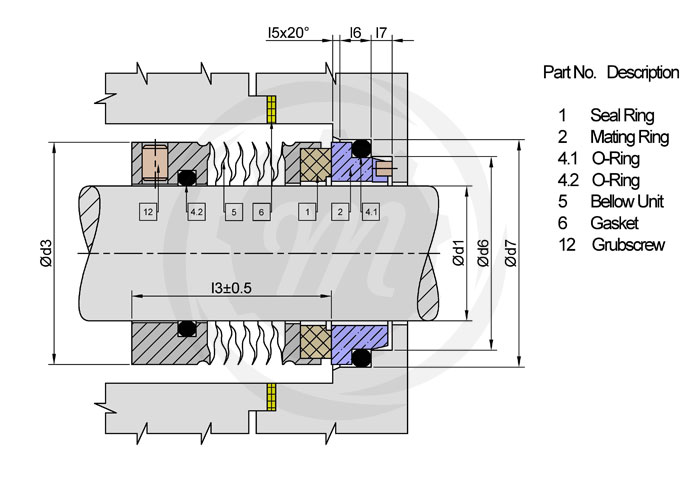

Bellows Mechanical Seal are a type of mechanical seal where the spring element is a bellows. This eliminates the need for a secondary dynamic seal e.g o-rings. Bellows Mechanical Seals are also known as non-pusher seals as they have a static secondary seal which stays in place against the shaft, sleeve or on the gland of the pump.

A bellows mechanical seal is used where a dynamic seal is deemed unsuitable for the application e.g high temperature medium slurry or high seal hysteresis.

The primary mechanical seal functions exactly the same as a standard mechanical seal except the spring element is now being replaced with a bellows. The friction from the dynamic seal (e.g o-ring) is not a consideration.

However if a bellows mechanical seal should fail it can be due to several reasons such as; poor wielding, product particulate getting into the bellows and causing the spring element to fail, chemical and/or abrasive attack or over-pressure.

If you have any query around how to install bellow mechanical seals for pumps or have some concerns around the seal failures, why not contact one of our seal specialists below to discuss it in more detail and find out how we can help solve your issues and get your process back up and running reliably again.

A Bellows seal does not have a secondary seal that must move along the shaft or sleeve to maintain seal face contact. The secondary seal is static state at all times, even when the pump is in operation.

Primary seal face wear is typically accommodated by welded metal or elastomeric bellows which move to assist in the compression of the rotary to stationary seal faces.

Bellows seals allow for high and low temperature applications when used in conjunction with metal bellows. They do not require a rotating secondary seal, which means it is not prone to secondary seal hang-up or fretting along the shaft or sleeve.

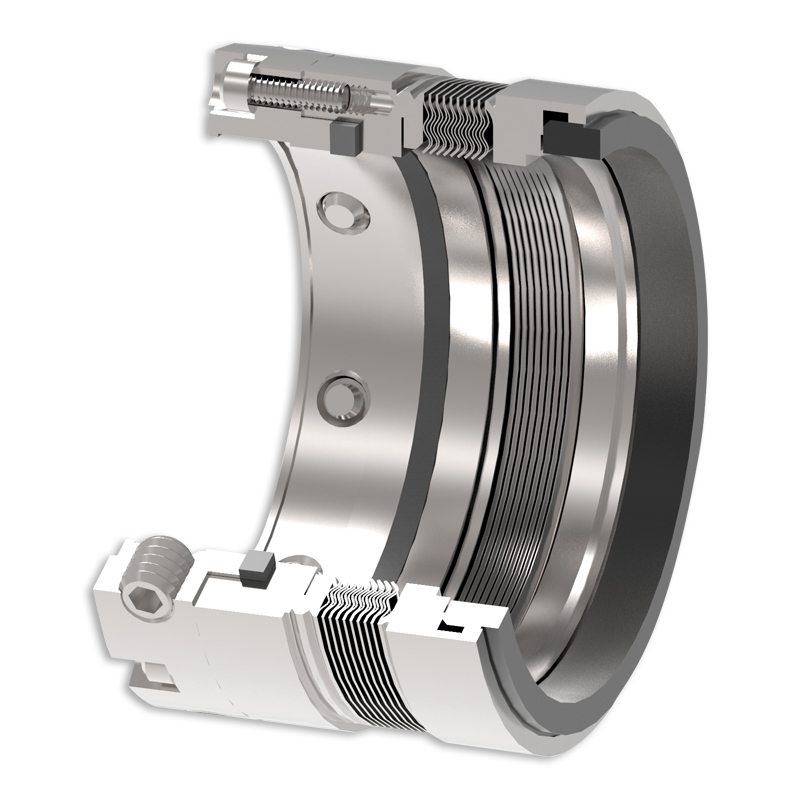

The Flexaseal Style 78A tandem cartridge seal is specifically designed for ruggedness and durability to withstand higher temperature or dirty services were leakage and emissions must be completely contained. Design elements include retained faces to allow for pressurized or unpressurized barrier systems, rotating metal bellows for self-cleaning and pilot gland to positively center the seal.

Style 78A is available in a High Temperature (HT) design with static O-Rings or with Grafoil Packing. This allows for operating temperatures up to 800F, while improving reliability by eliminating the dynamic secondary sealing element.

The Flexaseal Style 63A/66A cartridge seal is specifically designed for ruggedness and durability to withstand higher temperature or dirty services. The Style 63A features a stationary bellows unit for superior performance in applications that require higher shaft runount or large assembly tolerances. The Style 66 is a rotating bellows unit for enhanced solids handling.

Grafoil packing throughout allows for operating temperatures up to 800F, while improving reliability by eliminating the dynamic secondary sealing element.

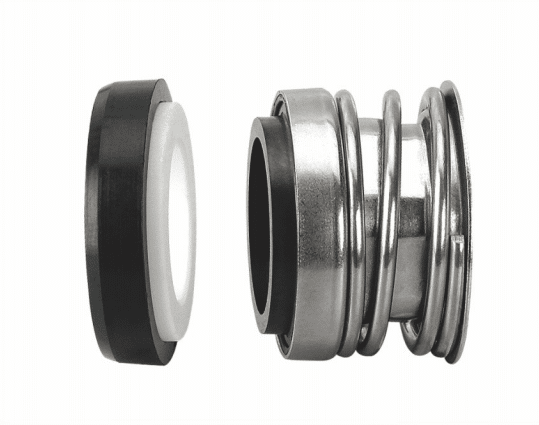

Rubber bellow seal – 21 is engineered under the firm direction of experienced quality controllers. These are widely used for universal general purpose for water / water based solution like fuels, oils and other allied fluid. These are uniquely designed for centrifugal pumps. These find their wide applications in various industries including water system, pulp and paper food processing, waste water treatment for petrochemical processing and many others allied industries. These are acclaimed for its compact design, high efficiency and less maintenance cost. These are attached with bellow seals protecting against twisting.

Eries Meqe502 Seals Specially Designed For High Temperature Application And Suitable For High Start – Up Toque Since The Bellows Unit Is Independent Of Torque Transmission. Graf Oil Is Secondary Member Having Excellent Temperature Rang Up To 4000c . Shrunk Fit Seal Face Design Minimize Face Distortion Restricting Leakage And Wear Rate To Very Low Level Under Of Condition.

Mechanical shaft seals are being manufacture by us for multiple applications where zero leakage is essential. Seals are available in designs capable of sealing corrosive, Volatile or abrasive fluids under a wide range of speeds, pressure and temperatures, especially at critical application and meeting followingread more...

Being the leading names in the industry, we are providing an extensive gamut of Rubber Bellow Seals. This seal is known for its flexibility, light weight, easy to install and durability. The offered seal is used for ensuring tight and leak proof sealing in the sewage pumps, water pumps and submersible pumps. Our seal isread more...

We are a topnotch Rubber Bellow Seal Manufacturer and Exporter from Gujarat, India. Our Rubber Bellow Seal comes at attractive price and is quite popular for its high quality. Harsh Pumps Make U74 Rubber Bellow Seal Series has Single Coil Spring Seal with Rubber Bellows, designed for Water, Oils & Light Duties.Special Materials can be offered to meet customer requirements.read more...

Our range of rubber bellow seal are extensively used in centrifugal pumps, plastic immersion pumps, vortex vacuum pumps, compressor for refrigeration of ammonia and various other applications. Fabricated using the premium quality raw material, these are known for their precise dimension, reliability and durability. Qualityread more...

... dual pressurized gas barrier metal bellows seal utilizing APGS non-contacting seal face technology. Welded metal bellows eliminate dynamic O-ring hang-up in a compact ...

LATTYseal U 6812 offers an instantaneous interchangeability of the rotating face permitting multiple use and cost reduction. Wide spectrum of rotating ...

... 425 ºC;• Inconel bellows available;• Cartridge easy to install;• Metal bellows provide better faces alignment;• Does not have dynamic gaskets;• Self-cleaning;• Adapts to API standard pumps;• Available ...

Cartridge seals for critical, toxic and emission control applications, where single seals are notaccepted;• Built-in pumping device improves barrier fl uid cooling;• Springs locations prevents contact ...

Burgmann H74-D Mechanical Seal called as PC04 are specialized in mechanical seals products. This device gives double seal and it can be rotated in any ...

FLEX MECH-Seal(china)Co.,ltd. is spent significant time in mechanical seals items including for auto cooling pump mechanical seals,for car air-layer ...

The PTFE bellows type mechanical seal, manufactured by Chinabase Machinery, can operate on a temperature range of -45°C up to 250°C on a pressure ≤1.2 Mpa and speed of ≤15 m/s. The stationary ...

The mechanical seals are designed to deliver excellent twin directional sealing performances in general purpose machines and are geared to operate in low to medium pressure applications. They are equipped ...

The MTM 51 series is an elastomer bellows type mechanical seal developed by Microtem. It is mainly used for general services machinery at low and medium pressure. This double directional ...

The MICROTEM double directional mechanical seal is with a single cylindrical spring is unbalanced and i elastomer bellows. It is used for general services machinery at low-medium pressure ...

The PK Seal features a single spring rubber bellows that will not wear the shaft or sleeve. It fits into shallow stuffing boxes and the flexible rotary face floats to compensate for misalignment.

... performance, the Type 1 elastomer bellows seal is widely recognized as the industry"s workhorse. Suitable for a wide range of service conditions ranging from water and steam to chemicals and corrosive ...

The BDFI™/BDFC™ (Bellows Double Flow Induction/Convection) is an innovative modular hybrid design, created using the inboard design of a BQFD™ and the outboard ...

Mechnical seal type 5030 / 5031 »with rubber bellowssingle-actingnon-anisotropicAreas of usestandard pumpwaster water pumpsupply engineeringgeneral industrial usemass production seal

Robust bellow seal with non-DIN cross-section, available inthree standard DIN working lengths and with stationaries to suitall common European housing sizes.

Structural Features: single end, balanced, independent direction of rotation, metal bellow, cartridge seal. The auxiliary seal ring is made of expanded graphite, which is suitable for complex operating conditions and mixed sealed mediums. This seal component is easy to install and adjust and has specifically great performance while used in medium-and-high viscosity and high or low temperature content.

Mechanical Seal (Metal Bellow) – Microsseals are one of the highest metal bellow mechanical seal manufacturers, manufacturing best metal bellow mechanical seal and supplier metal bellow seal design. Exciting one of the top most metal bellow seal Provider, manufacturer and exporter of the multiple types of mechanical seals, we supply the metal bellow seal manufactured and designed of very high quality raw materials.

"Metal Bellow Mechanical Seals" is lnherently balanced metal bellow mechanical seal. This seals are independent of direction of rotation. The unique feature of this type of seal is that, there is no dynamic "O" rings and therefore it will never hangup or damage the shaft and sleeve, it also has an ability to handle corrosive as well as abrasive & viscous media. These seals have self-cleaning & nonclogging construction. With selection of special bellow material it can be used in highly corrosive media.

We recognize and understand the vital role of metal bellow mechanical seal in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale metal bellow mechanical seal in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider metal bellow mechanical seal requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

In many cases, Cartridge Seals may contain the exact same major items that are sold separately as Component Seals. These pieces include the Rotary Seal and Stationary Face as well as other minor parts like O-rings or Gaskets all required at assembly. The advantage of using a Cartridge Seal is that the time required for installation, and even more importantly, the possibility of error during installation is dramatically reduced. When installing a Cartridge Seal, the necessity of having to measure internal components positioning on the shaft to achieve proper face loading is eliminated. Cartridge Seals come pre-assembled from the factory with all internal components assembled with proper face loading and all pieces in place, exactly where they should be. Cartridge Seals eliminate the need to handle delicate, polished parts such as Seal Faces that can be compromised by the presence of dirt, smudges and oils that can result from handling during assembly. So, for the easiest and most reliable Seal installation, Cartridge Seals go a long way towards helping you achieve trouble free startup and extended service life from your equipment.

Bellows seals are an excellent choice for applications where the process fluid is incompatible with common elastomers or where the cost of custom O-Rings is prohibitive. Chesterton provides a variety of bellows seals, including single and double seal designs for high-temperature and chemical applications.

8613371530291

8613371530291