burgmann mechanical seal price pricelist

Oct042016COMPLETE MECHANICAL SEAL, CARTEX-SNO/60-OO, BQ1VMG,317349, ID NR.058652004,MFG :BURGMANN ITEM NO.:1130200052Saudi ArabiaBombay Air CargoSET3119,43639,812

Mar052016Flowserve centrifugal pumpset, c/w Burgmann mechanical seals, siemens motors, coupling, coupling guards, heating jacketIndonesiaBombay Air CargoNOS61,143,514190,586

Oct292015BARE SHAFT PUMP MODEL SRP/100-80-200 FITTED WITH SKF BEARINGS, EAGLE BURGMANN CORBON / CERAMIC MECHANICAL SEALAustraliaChennai SeaNOS138,21738,217

Sep092015SPRING INBOARD FOR EAGLE BURGMANN MECHANICAL SEAL TYPE ; MD251, SIZE:48MM, MOC : HATELLOY-C, (1SET=12NOS)IndonesiaBombay Air CargoSET1550,1143,341

Sep092015SPRING OUTBOARD FOR EAGLE BURGMANN MECHANICAL SEAL TYPE ; MD251, SIZE:48MM, MOC : SS-316 (1 SET = 9 NOS)IndonesiaBombay Air CargoSET1518,7931,253

Sep092015SPRING INBOARD FOR EAGLE BURGMANN MECHANICAL SEAL TYPE ; MD251, SIZE:45MM, MOC : HATELLOY-C, (1SET=12NOS)IndonesiaBombay Air CargoSET1033,4103,341

Sep092015SPRING OUTBOARD FOR EAGLE BURGMANN MECHANICAL SEAL TYPE ; MD251, SIZE:45MM, MOC : SS-316 (1 SET = 9 NOS)IndonesiaBombay Air CargoSET1518,7931,253

Sep092015SPRING INBOARD FOR EAGLE BURGMANN MECHANICAL SEAL TYPE ; MD251, SIZE:65MM, MOC : HATELLOY-C, (1SET=12NOS)IndonesiaBombay Air CargoSET1043,4334,343

Sep092015SPRING OUTBOARD FOR EAGLE BURGMANN MECHANICAL SEAL TYPE ; MD251, SIZE:65MM, MOC : SS-316 (1 SET = 16 NOS)IndonesiaBombay Air CargoSET1031,1823,118

Jun162015MECHANICAL SEAL C174D (BURGMANN M74-D)MATERIAL: INBOARD SIG CARBON G9/EPDMOUT BOARD :SIQ CARBON G9 /EPDMVietnamChennai Air CargoSET150,64250,642

Jan012015MECHANICAL SEAL C174D (BURGMANN M74-D)MATERIAL: IBOARD SIC/CARBON G9/EPDMOUTBOARD SIC/CARBON G9/EPDM SIZE:70MMVietnamChennai Air CargoSET148,67048,670

Dec112014MECHANICAL SEALS,C174D (BURGMANN M74-D)MATERIAL NO: INBOARD SIC/CARBON G9/EPDMOUT BOARD SIC/CARBON G9/EPDMVietnamChennai Air CargoSET160,63960,639

We recognize and understand the vital role of eagle burgmann mechanical seals in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale eagle burgmann mechanical seals in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider eagle burgmann mechanical seals requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

Our component mechanical seal, burgmann mechanical seals, eagleburgmann mechanical seal are novel in technology and reasonable in structure. They sell well at home and abroad and are welcomed by the majority of users. We have formed a good reputation among users in the industry with "products that give you peace of mind, prices that make you satisfied, and services that move you", and have been universally recognized by users. We always focus on "technology development, people-oriented", and invest a lot of human and material resources to continuously improve and perfect our quality assurance system. After years of good faith management, our company has developed into an enterprise with strong technical force, strong economic strength, huge sales network and perfect after-sales service. We have established long-term and stable cooperation and service partnership with many large and medium-sized users at home and abroad, and have won wide recognition and praise from them.

The basic requirements of mechanical seal materials are mainly reflected in their material properties. The performance of the sealing material is an important factor to ensure effective sealing. The selection of the sealing material is mainly based on the working environment of the mechanical sealing element, such as the use temperature, working pressure, applicable working medium and movement mode.

With a new concept and a broad vision, we have constantly innovated and sought changes to create a series of high-quality Burgmann H7n/H75 Seal (Mechanical Seal TS H7N/TS H75). We continue to develop ourselves by training and promoting our employees, and we allow our employees to achieve professional improvement and human capital appreciation. Our company has established good cooperation relationship with various brand manufacturers, trade companies, wholesalers, retailers and other customer groups.

Hot Tags: h7n mechanical seal, China, suppliers, manufacturers, factory, customized, buy, quality, pricelist, quotation, low price, made in China, PTFE Bellows Mechanical Seals, QBW Cartridge Seals, seal kits for itt flygt pumps, CR16 Grundfos CR Mechanical Seal, 104 Mechanical Seal, Flygt Plug in Seals

Deriving additional value from critical rotating equipment can help a company improve efficiency, reduce operating expenses and extend operating life. Upgrades to components such as bearings, seals, couplings and controls keep rotating equipment operating at peak performance. A mechanical seal retrofit or upgrade is often a cost-effective answer to increasing throughput without the expense of investing in new equipment. Engineered seal retrofits can increase reliability, while reducing planned and unplanned outages that disrupt production and reduce revenue.

Mechanical seals are a component of a piece of rotating equipment. When defining the term “engineered,” look at both the component and the equipment in which it is installed. Currently, the common American National Standards Institute (ANSI) and American Petroleum Institute (API) pumps use standard stock seal designs, which are interchangeable from one manufacturer to another.

For larger, high-pressure, high-speed pumps and other unique pieces of rotating equipment, the seal and the equipment are typically designed for the application and use engineered mechanical seals with non-standard envelop dimensions, components, materials or face lubrication technologies.

Experience indicates that seal-related costs in many plants adhere to the 80/20 rule, meaning that 20 percent of the seals account for 80 percent of the total seal and/or rotating equipment maintenance cost. These so called bad actors are often the result of operational transients or issues that may be expensive to resolve or a result of using a seal that is simply too sensitive for the application.

For mechanical seal operation, it is a truism that “all seals leak.” It is when this leakage becomes excessive that equipment operations are in jeopardy. Failure data from a wide variety of industrial applications demonstrates that most mechanical seals are removed from service prematurely, not because the faces wore out but because damage to one of its components made it leak excessively.

Many failures occur randomly in frequency, which may imply that the seal is too sensitive to whatever event caused the component to fail. In such cases, upgrading the seal technology to make the mechanical seal less sensitive may be more beneficial than trying to avoid the event that caused the failure. Just replacing the damaged parts of a failed seal does little to uncover what caused the seal leakage and how to prevent subsequent problems.

The relationship between increased reliability and the converse effect on life cycle cost is certainly true for all mechanical components in a process system. Especially in the field of mechanical seals, this relationship is relevant since seal faces are inherently sensitive to leakage. The typical film thickness between the faces is a few microns and any significant deviation may exponentially increase the leak rate or damage the materials in a matter of seconds or minutes. Engineered seals may offer a good alternative to decrease the sensitivity of the seal parts to the typical and unusual operating conditions of a pump or any piece of rotating equipment with much improved reliability as a result.

A simple method to justify the cost of an engineered seal solution is by verifying the life cycle cost (LCC) of the seal and its environmental control system. Significant savings and excellent returns on investment (ROIs) can be achieved with engineered seal retrofits and upgrades in addressing the bad actors. The degree of technical risk and capital cost can vary widely depending on the nature of the equipment and the application.

A unique way of looking at seal problems is considering the entire operation, not just the failing component. While most seal companies are satisfied to just change-out a failing seal and leave it at that, a more holistic approach to solving seal problems is to go beyond the mechanical seal and look at the entire system.

Because a leaking seal is usually an indication of an even bigger problem, time should be taken to diagnose the whole application before beginning to reengineer the seal. The equipment in which the seal resides, along with the seal housing and hardware, process conditions and the auxiliary support systems, all affect the seal"s environment. When satisfied that the system as a whole is understood, a solution can be developed that will reduce the sensitivity of the seal to the specific application conditions.

The price of highly-engineered mechanical seals can start at $5,000 and run up to $100,000 per seal. Traditionally, mechanical seals have been treated as disposable items, when in fact they are repairable and improvable, regardless of the original manufacturer.

These highly engineered seals carry a lot of inherent or residual value and should not be treated as a commodity. As with any critical component or piece of equipment, these seals can be reengineered, recycled and transformed much in the same way as a pump or compressor would be remanufactured and reused.

An engineered seal adds value to the rotating equipment. Mechanical seals from any manufacturer can be reengineered to meet performance specifications within the same operating guidelines and with minimal changes to foundations, piping and other connections.

The reengineered seals have the same ‘form, fit and function" as the original seals, along with an enhancement of the redesign transformation process. Two case studies demonstrate the value of engineered seals.

Seal manufacturer engineers successfully upgraded two top-entry reactor seals for a major Gulf Coast chemical plant. In the existing, dual-pressurized seal arrangement, the “hard-on-hard” seal faces were extremely sensitive to lubrication-related damages due to a combination of high pressure (2,400 psi), high temperature (450 degrees F) and slow shaft speed (150 rpm). The seal"s short life span (three to six months) and its erratic leakage behavior caused unscheduled shutdowns and posed serious safety and environmental hazards.

This application was of particular concern because the chemicals in use were highly volatile and highly flammable, and therefore, the leakage problem required a highly engineered solution. Even though the original seals were not manufactured by the seal provider, its engineers knew that using an engineered upgrade approach to improve their reactor seals was possible.

The engineers examined the application from every angle to find the best solution that would extend the life of the seal, achieve a higher degree of reliability and eliminate the potential safety hazard. A proposal was made to retrofit the seal"s internal components with more robust face technology and materials that were not as prone to distress during all phases of the process.

A major gas producer in the Houston area was struggling with the seals on two between-bearing, 10-stage pumps that transport ethane at ambient temperature. Ethane was particularly difficult to seal in this application, as it was pumped at suction pressures above 600 psig and at the high pump shaft speed of 6,000 rpm. Low lubricity and the high vapor pressure of ethane made the lubrication aspect of this application challenging.

On top of these difficult conditions, the pump vintage year dated back to the 1970s when seal chambers were still stuffing boxes or had limited space for a beefy seal. Prediction, detection, containment and disposal of seal leakage were critical since the pumps were vital to the output of the plant and subject to an emission limit of 1,000 parts per million (ppm) as measured by EPA Method 21. The original seals were dual unpressurized equipped with API Plan 76 to dispose the leakage vapors to a flare system.

In Plan 76, a pressure switch at the outlet of a dry running back-up seal detected the onset of seal degradation when the primary, ethane lubricated seal leaked excessively and erratically. The cooling of the primary seal faces was achieved with a simple Plan 11 that connected from the second stage impeller. The lifetime of the original seals was poor, from days to a few months at best. Typical damages were heat cracks and severe wear of the seal faces.

A seal provider"s engineering team was asked to make recommendations to solve the problem and proposed an engineered seal face upgrade approach in combination with a change in the Plan 11. Instead of operating the primary seal faces on seal chamber pressures slightly above suction pressure, the engineers suggested maximizing the pressure in the seal chamber to create more vapor pressure margin. By changing the source connection for the primary seal flush, the mechanical seal would operate close to the discharge pressure of the pump.

A new close-clearance bushing in the bottom of the seal chamber was necessary to minimize the flush flow within acceptable rates. The back-up or safety seal from the original manufacturer as well as Plan 76 were left unchanged, as they appeared to work fine.

Also unique to this case was the limited space in which this solution was provided. The user looked at upgrading his pumps with compressor gas seal technology, which is the modern solution for this type of application, but found that this technology requires much more radial space then an old style API pump provides.

In addition, the initial cost, refurbishment costs and leakage rates of gas seals were much higher making the shrink fit face solution the lowest risk upgrade approach.

An engineered mechanical seal retrofit or upgrade transforms the original seal into a more robust, forgiving and reliable product, which can provide significant financial savings. This is why working with the seal manufacturer to “reengineer” seals and systems, not just replace them, is important.

Rather than treating mechanical seals as commodities and just “tossing them out” when they start to fail, upgrading offers a way to further a company"s investment in its rotating equipment and its components.

What are raw materials for metal bellow seals wholesale production? If this question asian coin with 100 on it asked, you will think about cost, security and performance of metal bellow seals wholesale. A producer is expected to confirm the source of raw material, decrease the cost for raw material and apply innovative technology, in order to improve the performance-cost ratio.

Now most of the manufacturers would examine their raw materials prior to processing. They may even invite third parties to check the materials and issue test reports. Stable partnerships with raw material suppliers are of great relevance to the metal bellow seals wholesale makers. This usually means that their raw materials will be guaranteed by price, quality and quantity.

Being an expert in the design and manufacture of grundfos pump seal kit, Guangzhou Lepu Machinery CO. Lepu cartridge type mechanical seal is manufactured by utilizing a tech pack - a comprehensive packet of design details. Through this, the product can meet customers" exact specifications.

Compact gland allows Lepu seal to be used in limited space. The product features the desired durability. It has a strong housing featuring impact resistance, which allows circuit boards to work stably in the case of vibration. Guangzhou Lepu Machinery CO. Get info! What properties are needed in metal bellow seals wholesale raw materials? A finest-quality metal bellow seals wholesale can"t become popular without well-selected raw materials.

With a track record of providing reliable manufacture services of teflon bellow, Guangzhou Lepu Machinery CO. There is an overseeing quality division to monitor aspects of product quality of Lepu teflon bellow. This division adopts statistical methods, probabilistic computing method and other ways to ensure its quality stability. The seal face uses high quality SSIC for stationary and rotary.

How much will it take for metal bellow seals wholesale materials? Material cost is a key focus in the manufacturing industry. All manufacturers do their endeavor to reduce the costs for raw materials.

So do the metal bellow seals wholesale producers. Material cost is closely related to other costs. If the manufacturer intends to reduce the costs for materials, technology is a solution. A successful manufacturer is always able to balance each expense.

Avail from is an exclusive collection of Shaft Seals which are constructed using premium quality basic material. These seals are available in a variety of sizes, and can be custom designed according to the client"s requirements. Owing to the striking features like durable finish standards, tensile strength and higherread more...

We are identified as one of the leading names in the market engaged in providing a wide range of Shaft Mechanical Seal to our valued clients.read more...

SEALS Range and Applications: Our Seals have a wide range of Mechanical Shaft Seals backed by over one decade of experience and expertise in Sealing Technology. We Manufacture highly efficient and reliable Mechanical Seals for Centrifugal Pumps, Turbine Pumps, Mixers, Agitators, Kneaders, Autoclaves, Compressors, Jet/Beamread more...

Sealdyne Systems is the leading Manufacturer, Exporter and Wholesaler of Mechanical Seals, Rotary Joints, Bearing Isolator and Centrifugal Pump etc. It includes with Single Springs, Conical Springs, Wave Springs and Multi Springs as well as Elastomer Bellow Seals, PTFE Bellow Seals designs. Non-Pusher seals includes Metalread more... Brochure

Incorporated in 2012, Gipfel Engineering is a widely accomplished manufacturer, exporter and service provider of Chemical Process Pumps & Mechanical Seals. Our product line includes Component Mechanical Seal, Bellow Mechanical Seal, and Cartridge Mechanical Seal. Owing to the qualitative fabrication, our range is widelyread more... Brochure

We “Macwell Seal are a Sole Proprietorship based firm, engaged as the foremost manufacturer of Mechanical Seal, Cartridge Seal, Unbalanced Seal in mumbai Maharashtra india

Mechanical seals are devices that are used to provide a seal at the point of entry or exit of a rotating shaft. Typically it is used to prevent the leakage of one high pressure fluid into a lower pressure fluid.read more... Brochure

Keeping in mind the precise demands of our clients, we offer a wide range ofMechanical Shaft Seals. This Mechanical Shaft Seal is manufactured using advanced machines and tools at our manufacturing unit. These products are highly demanded because of their high performance and long service life. These products can be availed atread more... Brochure

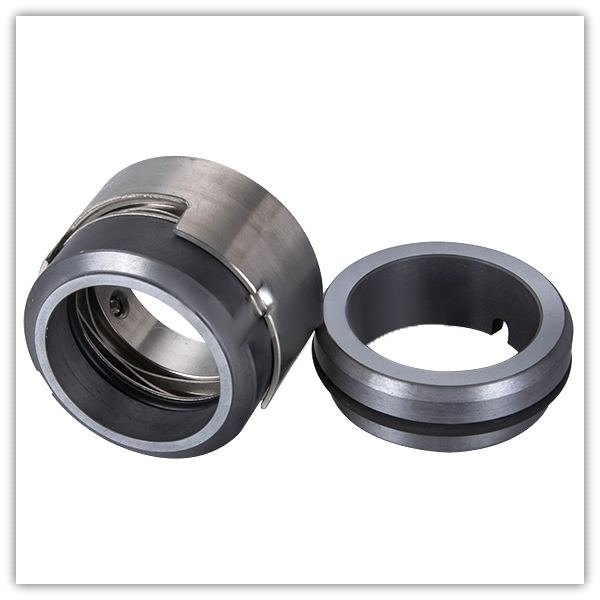

Burgmann cartex single cartridge seal is a world famous cartridge mechanical seal, this seals is popular used for pumps, agitator, mixer, and other rotating machines.

cartex signle cartridge seal is a standard mechanical seal, compared to the modular design with many complex parts, Cartex has been specifically engineered with a simple, robust design to achieve higher overall reliability and performance in extreme conditions.

Guangzhou Lepu machinery CO., LTD becomes one of the leading mechanical seal supplier in south of china, we focus in designing and manufacturing mechanical seal for many kinds of famous brand pumps, our mechanical seal cover many kinds of industry like food, petrol chemical, paper making, sea ship, and so on.

... pressurized gas barrier metal bellows seal utilizing APGS non-contacting seal face technology. Welded metal bellows eliminate dynamic O-ring hang-up in a compact cartridge that fits ANSI ...

• Drive mechanisms external to the product;• Seal faces positioned for maximum protection;• A dynamic elastomer moves on a non-metallic surface, eliminating fretting defects;• Hydraulically balanced;• Cartridge easy to ...

Burgmann H74-D Mechanical Seal called as PC04 are specialized in mechanical seals products. This device gives double seal and it can be rotated in any ...

The MTM10-11 is a conical spring mechanical seal developed by Microtem. It is mainly used for general services machinery at low and medium pressure. This unbalanced mechanical seal ...

The MTM 25_26, manufactured by MICROTEM, is a conical spring mechanical seal that can compensate positioning errors and withstand stresses created by vibrations. The contact surface can be made with silicon ...

... sealed tanks will have a mechanical seal of some sort. For many sanitary process vessels, the mixer must have some type of sealing barrier to provide either a dust tight vapor seal, a ...

mechanical seal for automotive engine cooling water pump, referred to as water seal, mainly composed of two parts: rotating ring and static ring. Static ring is installed ...

... harnesses the rotational energy of the pump shaft to vaporize the process fluid at a controlled rate, creating a stable gas film that lubricates the seal faces. Typical problems, such as dry-running wear, ...

The 3-D Seal is designed to be the foremost solution for high radial misalignment and high run out applications. By combining Garlock’s proven P/S®-II and expansion joint technologies into ...

The AESSEAL® API Type A, B and C single-seal range offers the user an unprecedented range of API engineered sealing solutions to suit all application ...

Mechnical seal type 5030 / 5031 »with rubber bellowssingle-actingnon-anisotropicAreas of usestandard pumpwaster water pumpsupply engineeringgeneral industrial usemass production ...

Balanced Bi-directional Built-in flushing connections External pressurization Fully split single seal, 2 x 2 segments, preassembled Installation and wear control Semi-cartridge Stationary springs

We manufacture face seals for hydraulic and pneumatic applications in the following designs:- rod seals and piston seals - single-acting - double-acting - rotatory seals ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

With more than ten years hard work and great emphasis on aftermarket services, A&S Seal Co., Ltd. has dominated a big market with growing knowledge and experiences in sealing industry.

The brands we provide: Parker seals, John Crane seals, Burgmann seals, SKF seals, NOK seals, NAK seals, Busak Shamban seals, Valqua seals, Merkel seals, Garlock seals, Trelleborg seals, Flowserve seals, TTO seals, etc.

The seals we supply :Mechanical Seals, Oil Seals, Hydraulic Seals, Shaft Seals, Lip Seals, Pump Seals, Dust Seals, Face Seals, Floating Seals, Piston Cup Seal, Packing, O-Rings and so on.

8613371530291

8613371530291